|

Nitro Engine

A nitro engine generally refers to an engine powered with a fuel that contains some portion (usually between 10% and 40%) of nitromethane mixed with methanol. Nitromethane is a highly combustible substance that is generally only used in very specifically designed engines found in Top Fuel drag racing and miniature internal combustion engines in radio control, control line and free flight model aircraft. The term "nitro" has come into use in the last few decades to describe these engines and has its origins in marketing hype in the model car market. For the fifty or so years prior to this term since the engines were first developed, they were simply referred to as "glow engines", but the term "nitro" has more impact in ad copy. These engines are actually fueled by methanol, but the fuel is often doped with nitromethane as a performance additive. The ignition system consists of a glow plug – hence the older term "glow" engine which has a coil of platinum-containing wire alloy, u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitromethane

Nitromethane, sometimes shortened to simply "nitro", is an organic compound with the chemical formula . It is the simplest organic nitro compound. It is a polar liquid commonly used as a solvent in a variety of industrial applications such as in extractions, as a reaction medium, and as a cleaning solvent. As an intermediate in organic synthesis, it is used widely in the manufacture of pesticides, explosives, fibers, and coatings. Nitromethane is used as a fuel additive in various motorsports and hobbies, e.g. Top Fuel drag racing and miniature internal combustion engines in radio control, control line and free flight model aircraft. Preparation Nitromethane is produced industrially by combining propane and nitric acid in the gas phase at 350–450 °C (662–842 °F). This exothermic reaction produces the four industrially significant nitroalkanes: nitromethane, nitroethane, 1-nitropropane, and 2-nitropropane. The reaction involves free radicals, including t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

2 Stroke Engine

A two-stroke (or two-stroke cycle) engine is a type of internal combustion engine that completes a power cycle with two strokes (up and down movements) of the piston during one power cycle, this power cycle being completed in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle during two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust (or scavenging) functions occurring at the same time. Two-stroke engines often have a high power-to-weight ratio, power being available in a narrow range of rotational speeds called the power band. Two-stroke engines have fewer moving parts than four-stroke engines. History The first commercial two-stroke engine involving cylinder compression is attributed to Scottish engineer Dugald Clerk, who patented his design in 1881. However, unlike most later two-st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Model Engine

A model engine is a small internal combustion engine typically used to power a radio-controlled aircraft, radio-controlled car, radio-controlled boat, free flight, control line aircraft, or ground-running tether car model. Because of the square–cube law, the behaviour of many engines does not always scale up or down at the same rate as the machine's size; usually at best causing a dramatic loss of power or efficiency, and at worst causing them not to work at all. Methanol and nitromethane are common fuels. Overview The fully functional, albeit small, engines vary from the most common single-cylinder two-stroke to the exotic single and multiple-cylinder four-stroke, the latter taking shape in boxer, v-twin, inline and radial form, a few Wankel engine designs are also used. Most model engines run on a blend of methanol, nitromethane, and lubricant (either castor or synthetic oil). Two-stroke model engines, most often designed since 1970 with Schnuerle porting for best per ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitrous Oxide Engine

A Nitrous Oxide Engine, or Nitrous Oxide System commonly referred to and known as NOS, is an internal combustion engine in which oxygen for burning the fuel comes from the decomposition of nitrous oxide, N2O, rather than air. The system increases the engine's power output by allowing fuel to be burned at a higher-than-normal rate, because of the higher partial pressure of oxygen injected with the fuel mixture. Nitrous oxide is not flammable at room temperature, it only becomes flammable under extensive pressure. Nitrous injection systems may be "dry", where the nitrous oxide is injected separately from fuel, or "wet" in which additional fuel is carried into the engine along with the nitrous. NOS may not be permitted for street or highway use, depending on local regulations. N2O use is permitted in certain classes of auto racing. Reliable operation of an engine with nitrous injection requires careful attention to the strength of engine components and to the accuracy of the mix ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitrous Oxide Fuel Blend

Nitrous oxide fuel blend propellants are a class of liquid rocket propellants that were intended in the early 2010s to be able to replace hydrazine as the standard storable rocket propellent in some applications. In nitrous-oxide fuel blends, the fuel and oxidizer are blended and stored; this is sometimes referred to as a ''mixed monopropellant''. Upon use, the propellant is heated or passed over a catalyst bed and the nitrous oxide decomposes into oxygen-rich gasses. Combustion then ensues. Special care is needed in the chemical formulation and engine design to prevent detonating the stored fuel. Overview The propellant used in a rocket engine plays an important role in both engine design and in design of the launch vehicle and related ground equipment to service the vehicle. Weight, energy density, cost, toxicity, risk of explosions, and other problems make it important for engineers to design rockets with appropriate propellants. The major classes of rocket fuels are: ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cubic Inch

The cubic inch (symbol in3) is a unit of volume in the Imperial units and United States customary units systems. It is the volume of a cube with each of its three dimensions (length, width, and height) being one inch long which is equivalent to 1/231 of a US gallon. The cubic inch and the cubic foot are used as units of volume in the United States, although the common SI units of volume, the liter, milliliter, and cubic meter, are also used, especially in manufacturing and high technology. One cubic inch is approximately . One cubic foot is equal to exactly because 123 = 1,728. One US gallon is equal to exactly . Notation conventions * The following abbreviations have been used to denote the cubic inch: cubic in, cu inch, cu in, cui, cu. in. * The IEEE standard symbol is: in3 * In internal combustion engines, the following abbreviations are used to denote cubic inch displacement: c.i.d., cid, CID, c.i., ci Equivalence with other units of volume 1 cubic inch (assuming a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air–fuel Ratio

Air–fuel ratio (AFR) is the mass ratio of air to a solid, liquid, or gaseous fuel present in a combustion process. The combustion may take place in a controlled manner such as in an internal combustion engine or industrial furnace, or may result in an explosion (e.g., a dust explosion, gas or vapor explosion or in a thermobaric weapon). The air–fuel ratio determines whether a mixture is combustible at all, how much energy is being released, and how much-unwanted pollutants are produced in the reaction. Typically a range of fuel to air ratios exists, outside of which ignition will not occur. These are known as the lower and upper explosive limits. In an internal combustion engine or industrial furnace, the air–fuel ratio is an important measure for anti-pollution and performance-tuning reasons. If exactly enough air is provided to completely burn all of the fuel, the ratio is known as the stoichiometric mixture, often abbreviated to stoich. Ratios lower than stoichiometri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Servo (radio Control)

Servos (also RC servos) are small, cheap, mass-produced servomotors or other actuators used for radio control and small-scale robotics. Most servos are rotary actuators although other types are available. Linear actuators are sometimes used, although it is more common to use a rotary actuator with a bellcrank and pushrod. Some types, originally used as sail winches for model yachting, can rotate continuously. Construction A typical servo consists of a small electric motor driving a train of reduction gears. A potentiometer is connected to the output shaft. Some simple electronics provide a closed-loop servomechanism. Operation The position of the output, measured by the potentiometer, is continually compared to the commanded position from the control (i.e., the radio control). Any difference gives rise to an error signal in the appropriate direction, which drives the electric motor either forwards or backwards, and moving the output shaft to the commanded position. When the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Needle Valve

A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates. Construction and operation An instrument needle valve uses a tapered pin to gradually open a space for fine control of flow. The flow can be controlled and regulated with the use of a spindle. A needle valve has a relatively small orifice with a long, tapered seat, and a needle-shaped plunger on the end of a screw, which exactly fits the seat. As the screw is turned and the plunger retracted, flow between the seat and the plunger is possible; however, until the plunger is completely retracted, the fluid flow is significantly impeded. Since it takes many turns of the fine-threaded screw to retract the plunger, precise regulation of the flow rate is easily possible. The virtue of the needle valve is from the vernier effect of the ratio between the needle's length and its diameter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Venturi Effect

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe. The Venturi effect is named after its discoverer, the 18th century Italian physicist, Giovanni Battista Venturi. Background In inviscid fluid dynamics, an incompressible fluid's velocity must ''increase'' as it passes through a constriction in accord with the principle of mass continuity, while its static pressure must ''decrease'' in accord with the principle of conservation of mechanical energy (Bernoulli's principle). Thus, any gain in kinetic energy a fluid may attain by its increased velocity through a constriction is balanced by a drop in pressure. By measuring pressure, the flow rate can be determined, as in various flow measurement devices such as Venturi meters, Venturi nozzles and orifice plates. Referring to the adjacent diagram, using Bernoulli's equation in the special case of steady, incompressible, inviscid flows (such as t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

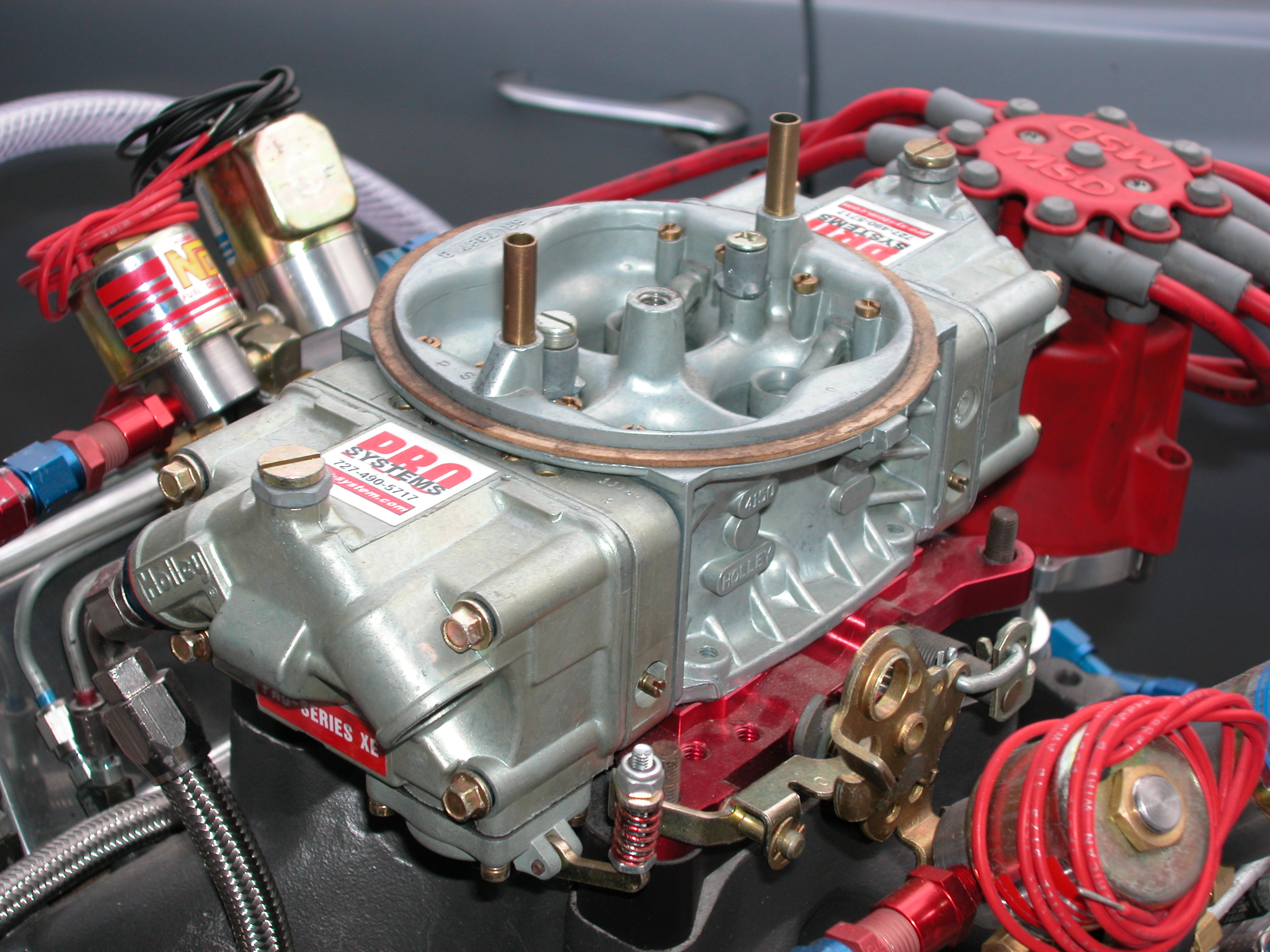

Carburetor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main metering circuit, however various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, however carburetors are still used by some small engines (e.g. lawnmowers, generators and concrete mixers) and motorcycles. Diesel engines have always used fuel injection instead of carburetors. Etymology The name "carburetor" is derived from the verb ''carburet'', which means "to combine with carbon," or in particular, "to enrich a gas by combining it with carbon or hydrocarbons." Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG). The name is spelled "carburetor" in American English ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Red Heat

The practice of using colours to determine the temperature of a piece of (usually) ferrous metal comes from blacksmithing. Long before thermometers were widely available it was necessary to know what state the metal was in for heat treating it and the only way to do this was to heat it up to a colour which was known to be best for the work. Chapman According to Chapman's ''Workshop Technology'', the colours which can be observed in steel are: Stirling In 1905, Stirling Consolidated Boiler Company published a slightly different set of values: See also *Black-body radiation *Color temperature Color temperature is the color of light emitted by an idealized opaque, non-reflective body at a particular temperature measured in kelvins. The color temperature scale is used to categorize the color of light emitted by other light sources ... * Incandescence References {{Reflist Metallurgy Temperature ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |