|

Material Handling

Material handling involves short-distance movement within the confines of a building or between a building and a transportation vehicle. It uses a wide range of manual, semi-automated, and automated equipment and includes consideration of the protection, storage, and control of materials throughout their manufacturing, warehousing, distribution, consumption, and disposal. Material handling can be used to create ''time and place utility'' through the handling, storage, and control of waste, as distinct from manufacturing, which creates ''form utility'' by changing the shape, form, and makeup of material. Role Material handling plays an important role in manufacturing and logistics. Almost every item of physical commerce has been transported on a conveyor or lift truck or another type of material handling equipment in manufacturing plants, warehouses, and retail stores. While material handling is usually required as part of every production worker's job, over 650,000 people in the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

US Navy 050831-N-3725R-004 Fork Trucks From The Amphibious Assault Ship USS Iwo Jima (LHD 7) Load Stores From The Pier To The Ship Prior To Getting Underway From Naval Station Norfolk

The United States of America (U.S.A. or USA), commonly known as the United States (U.S. or US) or America, is a country Continental United States, primarily located in North America. It consists of 50 U.S. state, states, a Washington, D.C., federal district, five major unincorporated territories, nine United States Minor Outlying Islands, Minor Outlying Islands, and 326 Indian reservations. The United States is also in Compact of Free Association, free association with three Oceania, Pacific Island Sovereign state, sovereign states: the Federated States of Micronesia, the Marshall Islands, and the Palau, Republic of Palau. It is the world's List of countries and dependencies by area, third-largest country by both land and total area. It shares land borders Canada–United States border, with Canada to its north and Mexico–United States border, with Mexico to its south and has maritime borders with the Bahamas, Cuba, Russia, and other nations. With a population of over 333 m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Present Value

In economics and finance, present value (PV), also known as present discounted value, is the value of an expected income stream determined as of the date of valuation. The present value is usually less than the future value because money has interest-earning potential, a characteristic referred to as the time value of money, except during times of zero- or negative interest rates, when the present value will be equal or more than the future value. Time value can be described with the simplified phrase, "A dollar today is worth more than a dollar tomorrow". Here, 'worth more' means that its value is greater than tomorrow. A dollar today is worth more than a dollar tomorrow because the dollar can be invested and earn a day's worth of interest, making the total accumulate to a value more than a dollar by tomorrow. Interest can be compared to rent. Just as rent is paid to a landlord by a tenant without the ownership of the asset being transferred, interest is paid to a lender by a borr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Warehouse

A warehouse is a building for storing goods. Warehouses are used by manufacturers, importers, exporters, wholesalers, transport businesses, customs, etc. They are usually large plain buildings in industrial parks on the outskirts of cities, towns, or villages. Warehouses usually have loading docks to load and unload goods from trucks. Sometimes warehouses are designed for the loading and unloading of goods directly from railways, airports, or seaports. They often have cranes and forklifts for moving goods, which are usually placed on ISO standard pallets and then loaded into pallet racks. Stored goods can include any raw materials, packing materials, spare parts, components, or finished goods associated with agriculture, manufacturing, and production. In India and Hong Kong, a warehouse may be referred to as a "godown". There are also godowns in the Shanghai Bund. History Prehistory and ancient history A warehouse can be defined functionally as a building in whic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Material Handling Equipment

Material handling equipment (MHE) is mechanical equipment used for the movement, storage, control, and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption, and disposal. The different types of equipment can be classified into four major categories: transport equipment, positioning equipment, unit load formation equipment, and storage equipment. Transport equipment Transport equipment is used to move material from one location to another (e.g., between workplaces, between a loading dock and a storage area, etc.), while positioning equipment is used to manipulate material at a single location. The major subcategories of transport equipment are conveyors, cranes, and industrial trucks. Material can also be transported manually using no equipment. Conveyors Conveyors are used when material is to be moved frequently between specific points over a fixed path and when there is a sufficient flow volume to justify the fixed co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Robot

An industrial robot is a robot system used for manufacturing. Industrial robots are automated, programmable and capable of movement on three or more axes. Typical applications of robots include welding, painting, assembly, disassembly, pick and place for printed circuit boards, packaging and labeling, palletizing, product inspection, and testing; all accomplished with high endurance, speed, and precision. They can assist in material handling. In the year 2020, an estimated 1.64 million industrial robots were in operation worldwide according to International Federation of Robotics (IFR). Types and features There are six types of industrial robots. Articulated robots Articulated robots are the most common industrial robots. They look like a human arm, which is why they are also called robotic arm or manipulator arm. Their articulations with several degrees of freedom allow the articulated arms a wide range of movements. Cartesian coordinate robots Cartesian ro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Human Factors And Ergonomics

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learning are to reduce human error, increase productivity, and enhance safety, system availability, and comfort with a specific focus on the interaction between the human and the engineered system. The field is a combination of numerous disciplines, such as psychology, sociology, engineering, biomechanics, industrial design, physiology, anthropometry, interaction design, visual design, user experience, and user interface design. Human factors research employs methods and approaches from these and other knowledge disciplines to study human behavior and generate data relevant to the four primary goals above. In studying and sharing learning on the design of equipment, devices, and processes that fit the human body and its cognitive abilities, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conveyor System

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors (floor and overhead) as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys. Industries where used Conveyor systems are used widespread across a range of industries due to the numerous benefits they provide. * Conveyors are able to safely tr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

College-Industry Council On Material Handling Education

The College-Industry Council on Material Handling Education (CICMHE) is an US academic/industry council of the Material Handling Industry (MHI) that promotes increased awareness of material handling and logistics within the USA through a variety of educational and research activities. CICMHE was founded in 1952 and has served to connect practitioners with academics that teach and do research in material handling. Organization The main body of the council is composed of fifteen college and university educators that are elected to a four-year term and is governed by a four-member executive committee. Additional members are drawn from material handling equipment manufacturers, distributors, users and consultants, representatives of the business press, and professional staff members of organizations concerned with material handling education. CICMHE is organized into two working committees: * The Events Committee plans and executes structured events to facilitate learning and res ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bulk Material Handling

Bulk material handling is an engineering field that is centered on the design of equipment used for the handling of dry materials. Bulk materials are those dry materials which are powdery, granular or lumpy in nature, and are stored in heaps.http://practicalmaintenance.net/wp-content/uploads/Maintenance-of-Ash-Handling-Plants-and-Pneumatic-Conveying-Systems.pdf Examples of bulk materials are minerals, ores, coal, cereals, woodchips, sand, gravel, clay, cement, ash, salt, chemicals, grain, sugar, flour and stone in loose bulk form. It can also relate to the handling of mixed wastes. Bulk material handling is an essential part of all industries that process bulk ingredients, including: food, beverage, confectionery, pet food, animal feed, tobacco, chemical, agricultural, polymer, plastic, rubber, ceramic, electronics, metals, minerals, paint, paper, textiles and more. Major characteristics of bulk materials, so far as their handling is concerned, are: lump size, bulk weight (densi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automation

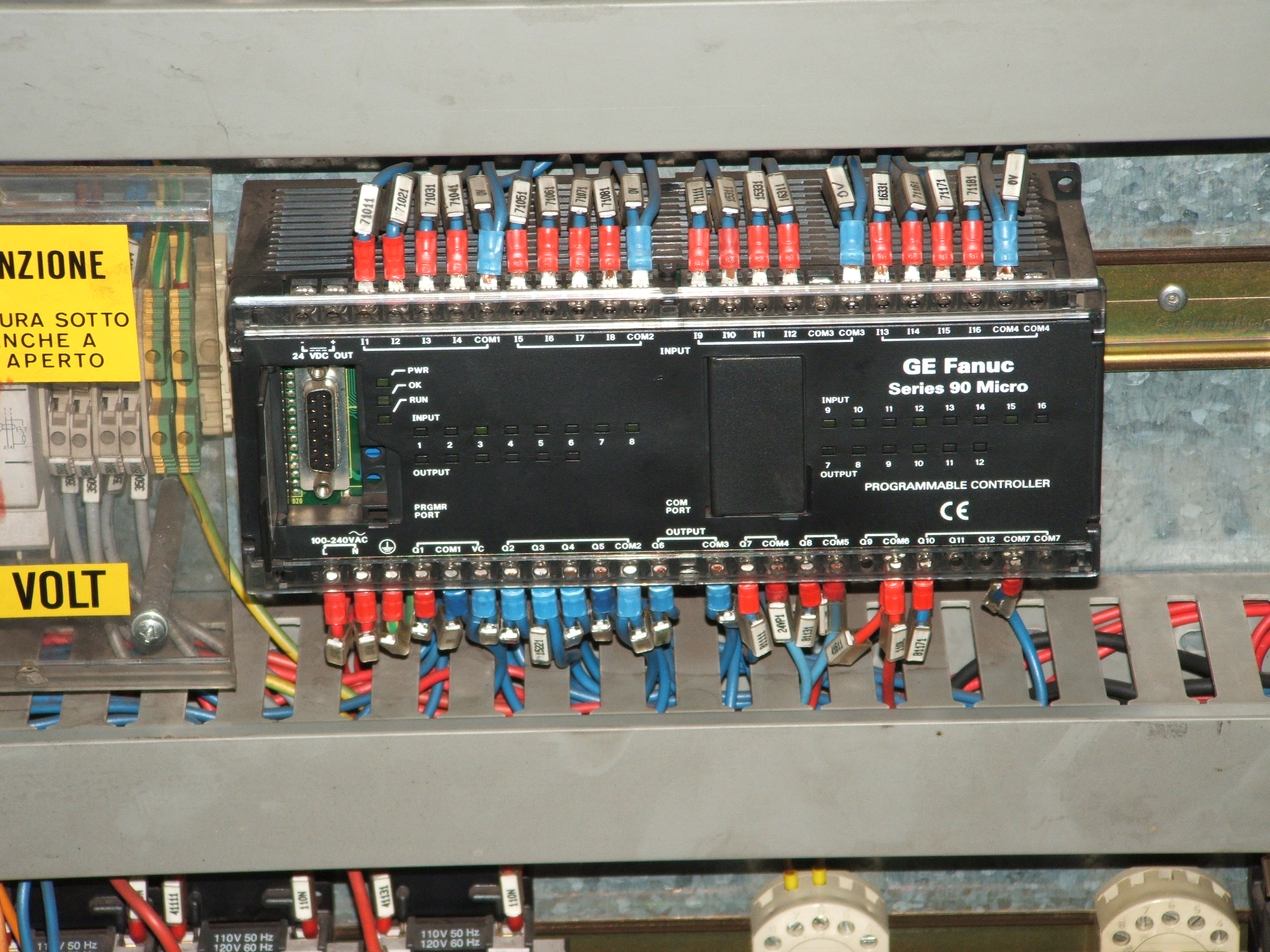

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision. Automation includes the use of various equipment and control systems such as machinery, processes in factories, boilers, and heat-treating ovens, switching on telephone networks, steering, and stabilization of ships, aircraft, and other applications and vehicles with reduced hu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automated Storage And Retrieval System

An automated storage and retrieval system (ASRS or AS/RS) consists of a variety of computer-controlled systems for automatically placing and retrieving loads from defined storage locations. Automated storage and retrieval systems (AS/RS) are typically used in applications where: * There is a very high volume of loads being moved into and out of storage * Storage density is important because of space constraints * No value is added in this process (no processing, only storage and transport) * Accuracy is critical because of potential expensive damages to the load An AS/RS can be used with standard loads as well as nonstandard loads, meaning that each standard load can fit in a uniformly-sized volume; for example, the film canisters in the image of the Defense Visual Information Center are each stored as part of the contents of the uniformly sized metal boxes, which are shown in the image. Standard loads simplify the handling of a request of an item. In addition, audits of the ac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

FANUC R2000iB AtWork

FANUC ( or ; often styled Fanuc) is a Japanese group of companies that provide automation products and services such as robotics and computer numerical control wireless systems. These companies are principally of Japan, Fanuc America Corporation of Rochester Hills, Michigan, USA, and FANUC Europe Corporation S.A. of Luxembourg. FANUC is the largest maker of industrial robots in the world. FANUC had its beginnings as part of Fujitsu developing early numerical control (NC) and servo systems. FANUC is acronym for Fuji Automatic NUmerical Control. History In 1955, Fujitsu Ltd. approached Seiuemon Inaba( :ja:稲葉清右衛門), who was then a young engineer, to lead a new subsidiary purposed to make the field of numerical control. This nascent form of automation involved sending instructions encoded into punched cards or magnetic tape to motors that controlled the movement of tools, effectively creating programmable versions of the lathes, presses, and milling machines. W ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |