|

Manufacturing Engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital. The manufacturing or production engineer's primary focus is to turn raw material into an updated or new product in the most effective, efficient & economic way possible. An example would be a company uses computer integrated technology in order for them to produce their product so that it is faster and uses less human labor. Overview Manufacturing Engineering is based on core industrial engineering and mechanical engineering skills, adding important elements from mechatronic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Prefabrication

Prefabrication is the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be located. The term is used to distinguish this process from the more conventional construction practice of transporting the basic materials to the construction site where all assembly is carried out. The term ''prefabrication'' also applies to the manufacturing of things other than structures at a fixed site. It is frequently used when fabrication of a section of a machine or any movable structure is shifted from the main manufacturing site to another location, and the section is supplied assembled and ready to fit. It is not generally used to refer to electrical or electronic components of a machine, or mechanical parts such as pumps, gearboxes and compressors which are usually supplied as separate items, but to sections of the body of the machine which in the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ford Assembly Line - 1913

Ford commonly refers to: * Ford Motor Company, an automobile manufacturer founded by Henry Ford * Ford (crossing), a shallow crossing on a river Ford may also refer to: Ford Motor Company * Henry Ford, founder of the Ford Motor Company * Ford Foundation, established by Henry and Edsel * Ford Australia * Ford Brasil * Changan Ford * Ford Motor Company of Canada, Canadian subsidiary * Ford of Britain * Ford of Europe, the successor of British, German and Irish subsidiaries * Ford Germany * Ford Lio Ho * Ford New Zealand * Ford Motor Company Philippines * Ford Romania * Ford SAF, the French subsidiary between 1916 and 1954 * Ford Motor Company of South Africa * Fordson, the tractor and truck manufacturing arm of the Ford Motor Company * Ford Vietnam * Ford World Rally Team (aka Ford Motor Co. Team prior to 2005), Ford Motor Company's full factory World Rally Championship team (1978–2012) * Ford Performance * Henry Ford & Son Ltd, Ireland * List of Ford vehicles, models referr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

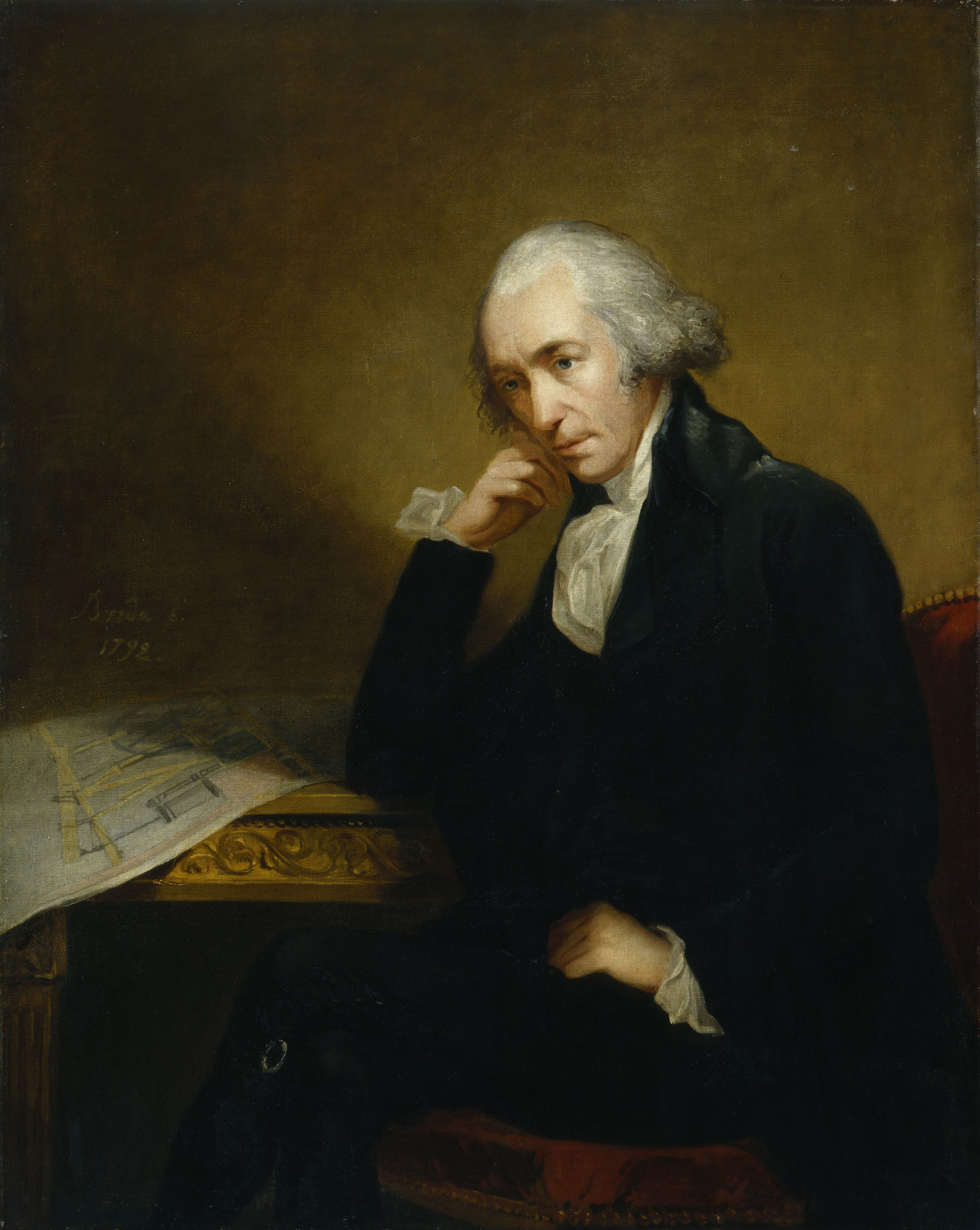

Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain, and many of the technological and architectural innovations were of British origin. By the mid-18th century, Britain was the world's leadi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Venetian Arsenal

The Venetian Arsenal ( it, Arsenale di Venezia) is a complex of former shipyards and armories clustered together in the city of Venice in northern Italy. Owned by the state, the Arsenal was responsible for the bulk of the Venetian republic's naval power from the late Middle Ages to the early modern period. It was "one of the earliest large-scale industrial enterprises in history". Overview Construction of the Arsenal began around 1104, during Venice's republican era. It became the largest industrial complex in Europe before the Industrial Revolution, spanning an area of about , or about fifteen percent of Venice.Giove, S., Rosato, P. & Breil, M.A multicriteria approach for the evaluation of the sustainability of re-use of historic buildings in Venice" ''Sustainability indicators and environmental valuation paper - Fondazione Eni Enrico Mattei.'' October 2008. Accessed 30 January 2010. Surrounded by a rampart, laborers and shipbuilders regularly worked within the Arsenal, b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron beam, friction, and ultrasound. While often a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Robots

An industrial robot is a robot system used for manufacturing. Industrial robots are automated, programmable and capable of movement on three or more axes. Typical applications of robots include welding, painting, assembly, disassembly, pick and place for printed circuit boards, packaging and labeling, palletizing, product inspection, and testing; all accomplished with high endurance, speed, and precision. They can assist in material handling. In the year 2020, an estimated 1.64 million industrial robots were in operation worldwide according to International Federation of Robotics (IFR). Types and features There are six types of industrial robots. Articulated robots Articulated robots are the most common industrial robots. They look like a human arm, which is why they are also called robotic arm or manipulator arm. Their articulations with several degrees of freedom allow the articulated arms a wide range of movements. Cartesian coordinate robots Cartesian robo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

William Edwards Deming

William Edwards Deming (October 14, 1900 – December 20, 1993) was an American engineer, statistician, professor, author, lecturer, and management consultant. Educated initially as an electrical engineer and later specializing in mathematical physics, he helped develop the sampling techniques still used by the U.S. Department of the Census and the Bureau of Labor Statistics. He is also known as the father of the quality movement and was hugely influential in post-WWII Japan. He is most well-known for his theories of management. Overview Deming received a BS in electrical engineering from the University of Wyoming at Laramie (1921), an MS from the University of Colorado (1925), and a PhD from Yale University (1928). Both graduate degrees were in mathematics and physics. He had an internship at Western Electric's Hawthorne Works in Cicero, Illinois, while studying at Yale. He later worked at the U.S. Department of Agriculture and the Census Department. While working unde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quality Control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements". This approach places emphasis on three aspects (enshrined in standards such as ISO 9001): # Elements such as controls, job management, defined and well managed processes, performance and integrity criteria, and identification of records # Competence, such as knowledge, skills, experience, and qualifications # Soft elements, such as personnel, integrity, confidence, organizational culture, motivation, team spirit, and quality relationships. Inspection is a major component of quality control, where physical product is examined visually (or the end results of a service are analyzed). Product inspectors will be provided with lists and descriptions of unacceptable product defects such as cracks or surface blemishes for example. History and introductio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

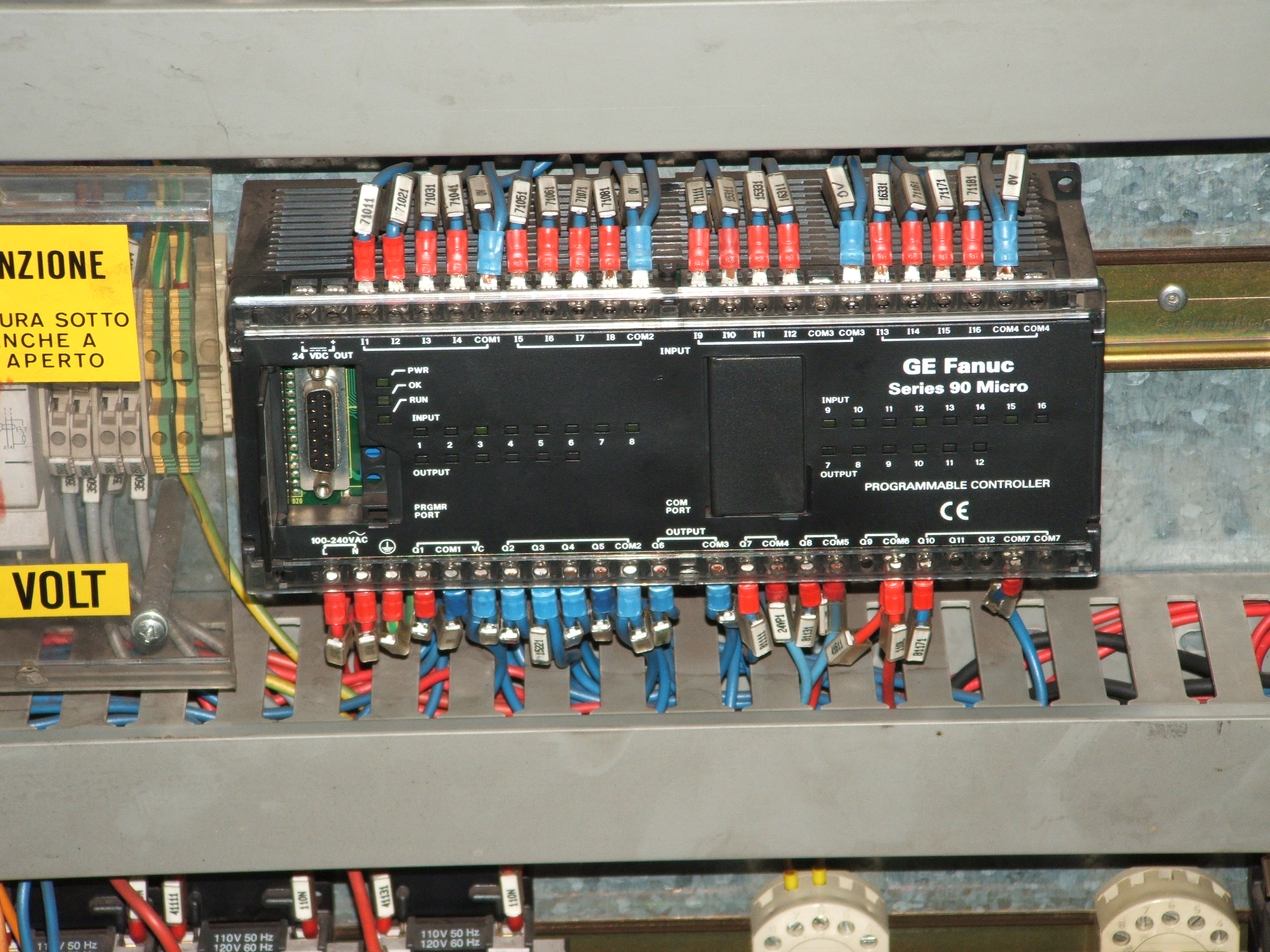

Numerical Control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be print ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Systems Engineering

Systems engineering is an interdisciplinary field of engineering and engineering management that focuses on how to design, integrate, and manage complex systems over their life cycles. At its core, systems engineering utilizes systems thinking principles to organize this body of knowledge. The individual outcome of such efforts, an engineered system, can be defined as a combination of components that work in synergy to collectively perform a useful function. Issues such as requirements engineering, reliability, logistics, coordination of different teams, testing and evaluation, maintainability and many other disciplines necessary for successful system design, development, implementation, and ultimate decommission become more difficult when dealing with large or complex projects. Systems engineering deals with work-processes, optimization methods, and risk management tools in such projects. It overlaps technical and human-centered disciplines such as industrial engineeri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

FANUC 6-axis Welding Robots

FANUC ( or ; often styled Fanuc) is a Japanese group of companies that provide automation products and services such as robotics and computer numerical control wireless systems. These companies are principally of Japan, Fanuc America Corporation of Rochester Hills, Michigan, USA, and FANUC Europe Corporation S.A. of Luxembourg. FANUC is the largest maker of industrial robots in the world. FANUC had its beginnings as part of Fujitsu developing early numerical control (NC) and servo systems. FANUC is acronym for Fuji Automatic NUmerical Control. History In 1955, Fujitsu Ltd. approached Seiuemon Inaba( :ja:稲葉清右衛門), who was then a young engineer, to lead a new subsidiary purposed to make the field of numerical control. This nascent form of automation involved sending instructions encoded into punched cards or magnetic tape to motors that controlled the movement of tools, effectively creating programmable versions of the lathes, presses, and milling machines. W ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |