|

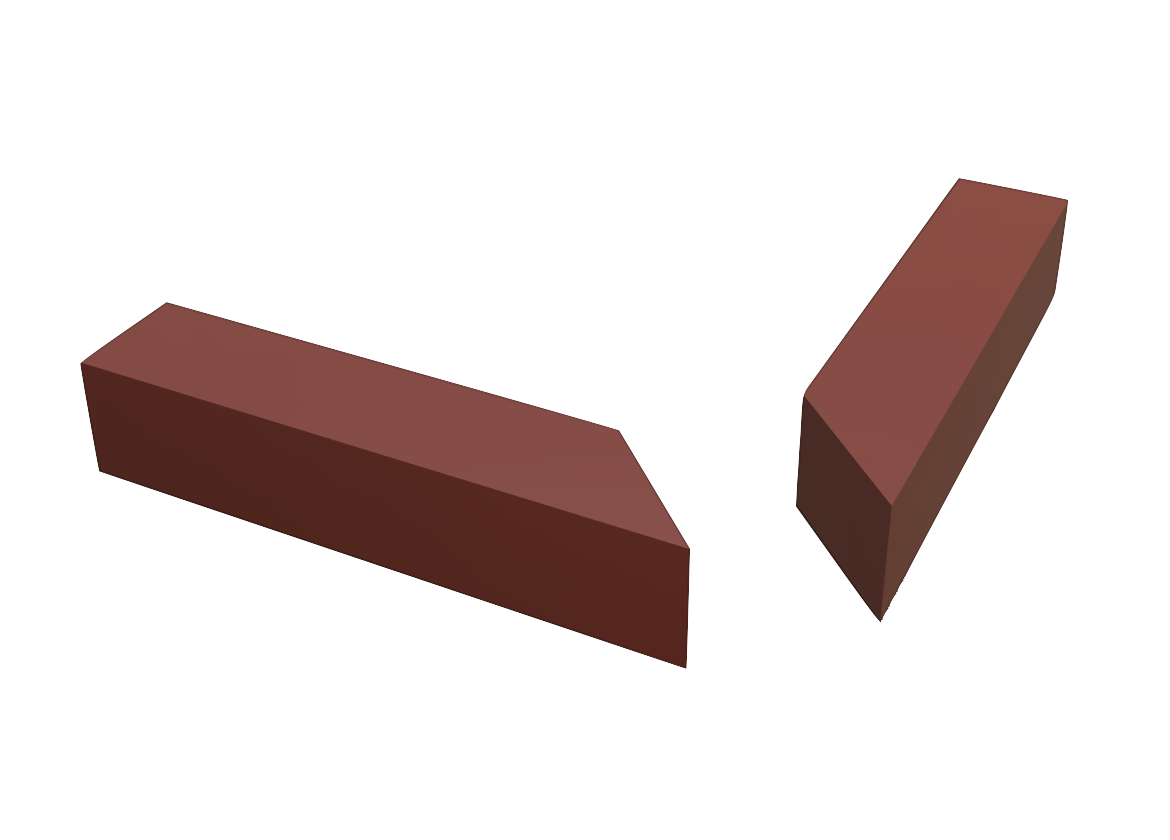

Mason's Mitre

A mason's mitre is a type of mitre joint, traditionally used in stonework or masonry but commonly seen in kitchen countertops. In a mason's mitre, the two elements being joined meet as for a butt joint but a small section of one member is removed creating a socket to receive the end of the other. A small mitre is made at the inside edges of the socket and on the end of the intersecting member so that edge treatments are carried through the joint appropriately. The mason's mitre allows the appearance of a mitre joint to be created with much less waste than occurs with a common mitre joint, in which triangular sections must be removed from the ends of both joint members. The terms "back mitre" and "mason's mitre" (or "miter") are often used interchangeably, but are different types of joints, and used for different purposes. Both joints are traditionally used in stone or woodwork. Neither joint requires that one part be coped (or fit) over the other. In the back mitre, the joints f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mitre Joint

A mitre joint (often miter in American English) is a joint made by cutting each of two parts to be joined, across the main surface, usually at a 45° angle, to form a corner, usually to form a 90° angle, though it can comprise any angle greater than 0 degrees. It is called beveling when the angled cut is done on the side, although the resulting joint is still a mitre joint. For woodworking, a disadvantage of a mitre joint is its weakness, but it can be strengthened with a spline (a thin wafer of wood inserted into a slot, usually arranged with the long grain of the spline across the short grain of the frame timber). There are two common variations of a splined mitre joint, one where the spline is long and runs the length of the mating surfaces and another where the spline is perpendicular to the joined edges. Common applications include picture frames, pipes, and molding. Non-perpendicular joints For mitre joints occurring at angles other than 90°, for materials of the s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stonework

Stonemasonry or stonecraft is the creation of buildings, structures, and sculpture using stone as the primary material. It is one of the oldest activities and professions in human history. Many of the long-lasting, ancient shelters, temples, monuments, artifacts, fortifications, roads, bridges, and entire cities were built of stone. Famous works of stonemasonry include the Egyptian pyramids, the Taj Mahal, Cusco's Incan Wall, Easter Island's statues, Angkor Wat, Borobudur, Tihuanaco, Tenochtitlan, Persepolis, the Parthenon, Stonehenge, the Great Wall of China, and Chartres Cathedral. Definition Masonry is the craft of shaping rough pieces of rock into accurate geometrical shapes, at times simple, but some of considerable complexity, and then arranging the resulting stones, often together with mortar, to form structures. *Quarrymen split sheets of rock, and extract the resulting blocks of stone from the ground. *Sawyers cut these rough blocks into cuboids, to required ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Masonry

Masonry is the building of structures from individual units, which are often laid in and bound together by mortar; the term ''masonry'' can also refer to the units themselves. The common materials of masonry construction are bricks, building stone such as marble, granite, and limestone, cast stone, concrete blocks, glass blocks, and adobe. Masonry is generally a highly durable form of construction. However, the materials used, the quality of the mortar and workmanship, and the pattern in which the units are assembled can substantially affect the durability of the overall masonry construction. A person who constructs masonry is called a mason or bricklayer. These are both classified as construction trades. Applications Masonry is commonly used for walls and buildings. Brick and concrete block are the most common types of masonry in use in industrialized nations and may be either load-bearing or non-load-bearing. Concrete blocks, especially those with hollow cores, offer v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Countertop

A countertop, also counter top, counter, benchtop, worktop (British English) or kitchen bench ( Australian or New Zealand English), bunker (Scottish English) is a raised, firm, flat, and horizontal surface. They are built for work in kitchens or other food preparation areas, bathrooms or lavatories, and workrooms in general. The surface is frequently installed upon and supported by cabinets, positioned at an ergonomic height for the user and the particular task for which it is designed. A countertop may be constructed of various materials with different attributes of functionality, durability and aesthetics, and may have built-in appliances, or accessory items relative to the intended application. In Australian and British English, the term ''counter'' is generally reserved for a surface of this type that forms a boundary between a space for public access and a space for workers to carry out service tasks. In other contexts, the term ''bench'' or ''benchtop'' is used. Kit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Butt Joint

A butt joint is a technique in which two pieces of material are joined by simply placing their ends together without any special shaping. The name "butt joint" comes from the way the material is joined. The butt joint is the simplest joint to make since it merely involves cutting the material to the appropriate length and butting them together. It is also the weakest because unless some form of reinforcement is used (see below), it relies upon glue or welding alone to hold it together. Because the orientation of the material usually presents only one end to a long gluing or welding surface, the resulting joint is inherently weak. Nonetheless, it generally provides sufficient strength in most cases, particularly when fasteners are used. The butt joint is widely used in many applications due to its simplicity, notably in rough carpentry and construction. Methods The butt joint is a very simple joint to construct. Members are simply docked (cut off) at the right angle and have a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coping (joinery) Coping or scribing is the woodworking technique of shaping the end of a moulding or frame component to neatly fit the contours of an abutting member. Joining tubular members in metalworking is also referred to as a cope, or sometimes a "fish mouth joint" or saddle joint. Most English-speaking countries outside the Unit |