|

M5 Fiber

M5 fiber (polyhydroquinone-diimidazopyridine or PIPD) is a high-strength synthetic fiber first developed by the Dutch chemical firm AkzoNobel. It is produced in the United States by the Magellan Systems International, which became a division of DuPont. Preparation M5 fiber is prepared by a condensation polymerization between tetraaminopyridine and dihydroxyterephthalic acid using diphosphorus pentoxide as a dehydrating agent. The polymer mixture is then heated and extruded to form brightly blue polymer fibers. The fibers are then washed extensively with water and base in order to remove the phosphoric acid generated by the hydration of diphosphorus pentoxide from the polymer. To remove water from the fiber structure and enable the intermolecular hydrogen bonds to be created, thus increasing the strength of the polymer, the fiber is heated and exposed to controlled stress. This aligns the molecular structure of the fiber in a better configuration for tensile and compressive stre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrogen Bonds

In chemistry, a hydrogen bond (or H-bond) is a primarily electrostatic force of attraction between a hydrogen (H) atom which is covalently bound to a more electronegative "donor" atom or group (Dn), and another electronegative atom bearing a lone pair of electrons—the hydrogen bond acceptor (Ac). Such an interacting system is generally denoted , where the solid line denotes a polar covalent bond, and the dotted or dashed line indicates the hydrogen bond. The most frequent donor and acceptor atoms are the second-row elements nitrogen (N), oxygen (O), and fluorine (F). Hydrogen bonds can be intermolecular (occurring between separate molecules) or intramolecular (occurring among parts of the same molecule). The energy of a hydrogen bond depends on the geometry, the environment, and the nature of the specific donor and acceptor atoms and can vary between 1 and 40 kcal/mol. This makes them somewhat stronger than a van der Waals interaction, and weaker than fully covalent ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dyneema

Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene, (HMPE), it has extremely long chains, with a molecular mass usually between 3.5 and 7.5 million amu. The longer chain serves to transfer load more effectively to the polymer backbone by strengthening intermolecular interactions. This results in a very tough material, with the highest impact strength of any thermoplastic presently made. UHMWPE is odorless, tasteless, and nontoxic. It embodies all the characteristics of high-density polyethylene (HDPE) with the added traits of being resistant to concentrated acids and alkalis, as well as numerous organic solvents. It is highly resistant to corrosive chemicals except oxidizing acids; has extremely low moisture absorption and a very low coefficient of friction; is self-lubricating (see boundary lubrication); and is highly resistant to abrasion, in some forms being 15 times more resistant t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

UHMWPE

Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene, (HMPE), it has extremely long chains, with a molecular mass usually between 3.5 and 7.5 million amu. The longer chain serves to transfer load more effectively to the polymer backbone by strengthening intermolecular interactions. This results in a very tough material, with the highest impact strength of any thermoplastic presently made. UHMWPE is odorless, tasteless, and nontoxic. It embodies all the characteristics of high-density polyethylene (HDPE) with the added traits of being resistant to concentrated acids and alkalis, as well as numerous organic solvents. It is highly resistant to corrosive chemicals except oxidizing acids; has extremely low moisture absorption and a very low coefficient of friction; is self-lubricating (see boundary lubrication); and is highly resistant to abrasion, in some forms being 15 times more resistant to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Twaron

Twaron (a brand name of Teijin Aramid) is a para-aramid. It is a heat-resistant and strong synthetic fibre developed in the early 1970s by the Dutch company Akzo Nobel's division Enka BV, later Akzo Industrial Fibers. The research name of the para-aramid fibre was originally Fiber X, but it was soon called Arenka. Although the Dutch para-aramid fiber was developed only a little later than DuPont's Kevlar, the introduction of Twaron as a commercial product came much later than Kevlar due to financial problems at the AKZO company in the 1970s. History This is a chronology of the development of Twaron: * In 1960s a research program starts for "Fiber X." * In 1972 the ENKA Research laboratory develops a para-aramid called Arenka. * In 1973 Akzo decides to use sulfuric acid (H2SO4) as a solvent for spinning. * In 1974 New process route was found at Akzo Research laboratory, using N-methylpyrrolidone (NMP) with a co-solvent (auxiliary solvent) with an ionic component (Calcium Chloride ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kevlar

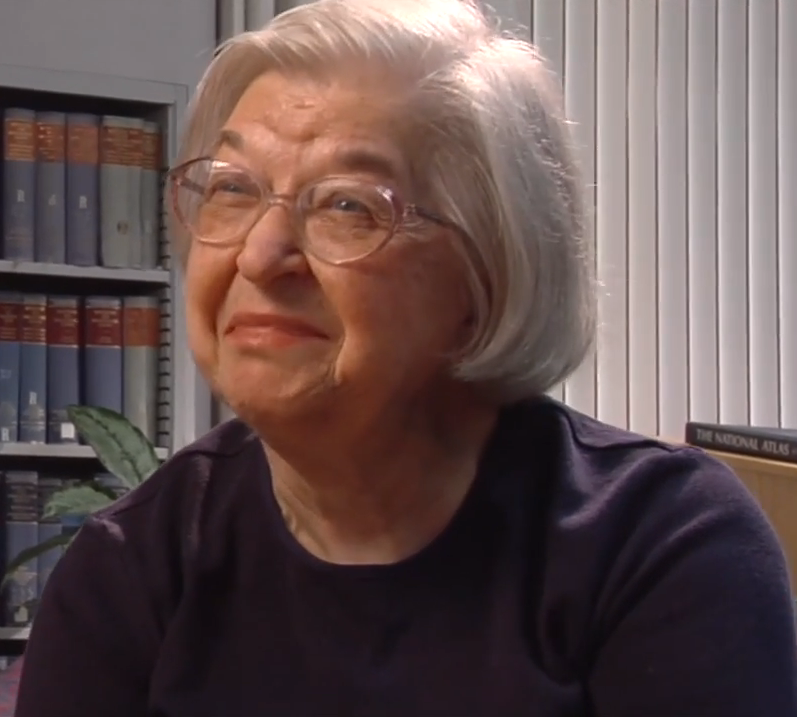

Kevlar (para-aramid) is a strong, heat-resistant synthetic fiber, related to other aramids such as Nomex and Technora. Developed by Stephanie Kwolek at DuPont in 1965, the high-strength material was first used commercially in the early 1970s as a replacement for steel in racing tires. It is typically spun into ropes or fabric sheets that can be used as such, or as an ingredient in composite material components. Kevlar has many applications, ranging from bicycle tires and racing sails to bulletproof vests, all due to its high tensile strength-to-weight ratio; by this measure it is five times stronger than steel. It is also used to make modern marching drumheads that withstand high impact; and for mooring lines and other underwater applications. A similar fiber called Twaron with the same chemical structure was developed by Akzo in the 1970s; commercial production started in 1986, and Twaron is now manufactured by Teijin. History Poly-paraphenylene terephthalamide (K2 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aramids

Aramid fibers, short for aromatic polyamide, are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in marine cordage, marine hull reinforcement, and as an asbestos substitute. The chain molecules in the fibers are highly oriented along the fiber axis. As a result, a higher proportion of the chemical bond contributes more to fiber strength than in many other synthetic fibers. Aramids have a very high melting point (>500 °C). Common aramid brand names include Kevlar, Nomex, and Twaron. Terminology and chemical structure ''Aramid'' is a shortened form of aromatic polyamide. The term was introduced in 1972, accepted in 1974 by the Federal Trade Commission of the USA as the name of a generic category of fiber distinct from nylon, and adopted by the International Standards Organisation in 1977. Aromatic in the name refers to the presence of aromatic rings of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tensile Strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials the ultimate tensile strength is close to the yield point, whereas in ductile materials the ultimate tensile strength can be higher. The ultimate tensile strength is usually found by performing a tensile test and recording the engineering stress versus strain. The highest point of the stress–strain curve is the ultimate tensile strength and has units of stress. The equivalent point for the case of compression, instead of tension, is called the compressive strength. Tensile strengths are rarely of any consequence in the design of ductile members, but they are important with brittle members. They are tabulated for common materials such as alloys, composite materials, ceramics, plastics, and wood. Definition The ultimate tensile streng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phosphoric Acid

Phosphoric acid (orthophosphoric acid, monophosphoric acid or phosphoric(V) acid) is a colorless, odorless phosphorus-containing solid, and inorganic compound with the chemical formula . It is commonly encountered as an 85% aqueous solution, which is a colourless, odourless, and non- volatile syrupy liquid. It is a major industrial chemical, being a component of many fertilizers. The compound is an acid. Removal of all three ions gives the phosphate ion . Removal of one or two protons gives dihydrogen phosphate ion , and the hydrogen phosphate ion , respectively. Phosphoric acid forms esters, called organophosphates. The name "orthophosphoric acid" can be used to distinguish this specific acid from other "phosphoric acids", such as pyrophosphoric acid. Nevertheless, the term "phosphoric acid" often means this specific compound; and that is the current IUPAC nomenclature. Production Phosphoric acid is produced industrially by one of two routes, wet processes and dry. We ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Synthetic Fiber

Synthetic fibers or synthetic fibres (in British English; see spelling differences) are fibers made by humans through chemical synthesis, as opposed to natural fibers that are directly derived from living organisms, such as plants (like cotton) or fur from animals. They are the result of extensive research by scientists to replicate naturally occurring animal and plant fibers. In general, synthetic fibers are created by extruding fiber-forming materials through spinnerets, forming a fiber. These are called synthetic or artificial fibers. The word polymer comes from a Greek prefix "poly" which means "many" and suffix "mer" which means "single units". (Note: each single unit of a polymer is called a monomer). Early experiments The first fully synthetic fiber was glass. Joseph Swan invented one of the first artificial fibers in the early 1880s; today it would be called semisynthetic in precise usage. His fiber was drawn from a cellulose liquid, formed by chemically modifying th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diphosphorus Pentoxide

Phosphorus pentoxide is a chemical compound with molecular formula P4 O10 (with its common name derived from its empirical formula, P2O5). This white crystalline solid is the anhydride of phosphoric acid. It is a powerful desiccant and dehydrating agent. Structure Phosphorus pentoxide crystallizes in at least four forms or polymorphs. The most familiar one, a metastable form (shown in the figure), comprises molecules of P4O10. Weak van der Waals forces hold these molecules together in a hexagonal lattice (However, in spite of the high symmetry of the molecules, the crystal packing is not a close packing). The structure of the P4O10 cage is reminiscent of adamantane with ''T''d symmetry point group. It is closely related to the corresponding anhydride of phosphorous acid, P4O6. The latter lacks terminal oxo groups. Its density is 2.30 g/cm3. It boils at 423 °C under atmospheric pressure; if heated more rapidly it can sublimate. This form can be made by condensing the vapo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |