|

Leavitt-Riedler Pumping Engine

The Leavitt-Riedler Pumping Engine (1894) is a historic steam engine located in the former Chestnut Hill High Service Pumping Station, in Boston, Massachusetts. It has been declared a historic mechanical engineering landmark by the American Society of Mechanical Engineers. The pumping station was decommissioned in the 1970s, and turned into the Metropolitan Waterworks Museum in 2011. The engine drew steam from a coal-fired boiler, and had a pump valve mechanism which allowed its high-speed operation at a hydraulic head of . The engine was designed by engineer Erasmus Darwin Leavitt, Jr., of Cambridge, Massachusetts, with a pump valve invented by Prof. Alois Riedler of the Royal Technical College of Charlottenburg (now the Technical University of Berlin) in Berlin, Germany. It was built by N. F. Palmer Jr. & Co. and the Quintard Iron Works, in New York. In 1894, it was installed as Engine No. 3 of the Chestnut Hill High Station, later named the Boston Water Works. At its norm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leavitt-Riedler Pumping Engine

The Leavitt-Riedler Pumping Engine (1894) is a historic steam engine located in the former Chestnut Hill High Service Pumping Station, in Boston, Massachusetts. It has been declared a historic mechanical engineering landmark by the American Society of Mechanical Engineers. The pumping station was decommissioned in the 1970s, and turned into the Metropolitan Waterworks Museum in 2011. The engine drew steam from a coal-fired boiler, and had a pump valve mechanism which allowed its high-speed operation at a hydraulic head of . The engine was designed by engineer Erasmus Darwin Leavitt, Jr., of Cambridge, Massachusetts, with a pump valve invented by Prof. Alois Riedler of the Royal Technical College of Charlottenburg (now the Technical University of Berlin) in Berlin, Germany. It was built by N. F. Palmer Jr. & Co. and the Quintard Iron Works, in New York. In 1894, it was installed as Engine No. 3 of the Chestnut Hill High Station, later named the Boston Water Works. At its norm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gallon

The gallon is a unit of volume in imperial units and United States customary units. Three different versions are in current use: *the imperial gallon (imp gal), defined as , which is or was used in the United Kingdom, Ireland, Canada, Australia, New Zealand, and some Caribbean countries; *the US gallon (US gal), defined as , (231 cubic inches) which is used in the US and some Latin American and Caribbean countries; and *the US dry gallon ("usdrygal"), defined as US bushel (exactly ). There are two pints in a quart and four quarts in a gallon. Different sizes of pints account for the different sizes of the imperial and US gallons. The IEEE standard symbol for both US (liquid) and imperial gallon is gal, not to be confused with the gal (symbol: Gal), a CGS unit of acceleration. Definitions The gallon currently has one definition in the imperial system, and two definitions (liquid and dry) in the US customary system. Historically, there were many definitions and redefiniti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Historic American Engineering Record In Massachusetts

History (derived ) is the systematic study and the documentation of the human activity. The time period of event before the invention of writing systems is considered prehistory. "History" is an umbrella term comprising past events as well as the memory, discovery, collection, organization, presentation, and interpretation of these events. Historians seek knowledge of the past using historical sources such as written documents, oral accounts, art and material artifacts, and ecological markers. History is not complete and still has debatable mysteries. History is also an academic discipline which uses narrative to describe, examine, question, and analyze past events, and investigate their patterns of cause and effect. Historians often debate which narrative best explains an event, as well as the significance of different causes and effects. Historians also debate the nature of history as an end in itself, as well as its usefulness to give perspective on the problems of the p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Purdue University Press

Purdue University Press, founded in 1960, is a university press that is part of Purdue University. It is a unit of Purdue University Libraries. History An administrative unit of Purdue University Libraries, Purdue University Press has its roots in the 1960 founding of Purdue University Studies by President Frederick Hovde on a $12,000 grant from the Purdue Research Foundation. This was the result of a committee appointed by Hovde after the Department of English lamented the lack of publishing venues in the humanities. The first editorial board was headed by Robert B. Ogle. William Whalen, director of the Office of Publications, became the part-time director of Purdue University Studies. Verna Emery was managing editor from 1977 to 1990, succeeded by Margaret Hunt who served until 2008. On September 12, 1974, Purdue University Studies became Purdue University Press. In June 1992 Whalen retired and David Sanders was appointed the first full-time director of the press serving until ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

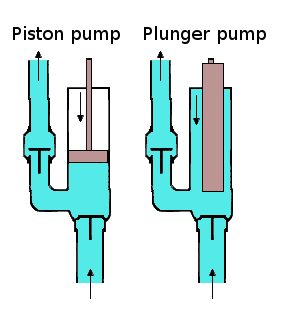

Plunger Pump

A plunger pump is a type of positive displacement pump where the high-pressure seal is stationary and a smooth cylindrical plunger slides through the seal. This makes them different from piston pumps and allows them to be used at higher pressures. This type of pump is often used to transfer municipal and industrial sewage. History The invention of the plunger pump is attributed to Samuel Morland based on a patent of 1675. Operation Piston pumps and plunger pumps are positive displacement pumps that use a plunger or piston to move media through a cylindrical chamber. The plunger or piston is actuated by a steam powered, pneumatic, hydraulic, or electric drive. Rotary piston and plunger pumps use a crank mechanism to create a reciprocating motion along an axis, which then builds pressure in a cylinder or working barrel to force gas or fluid through the pump. The pressure in the chamber actuates the valves at both the suction and discharge points. Plunger pumps are used in appli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bellcrank

A bellcrank is a type of crank that changes motion through an angle. The angle can be any angle from 0 to 360 degrees, but 90 degrees and 180 degrees are most common. The name comes from its first use, changing the vertical pull on a rope to a horizontal pull on the striker of a bell, used for calling staff in large houses or commercial establishments. Angles A typical 90 degree bellcrank consists of an "L" shaped crank pivoted where the two arms of the L meet. Moving rods (or cables or ropes) are attached to the ends of the L arms. When one is pulled, the L rotates around the pivot point, pulling on the other arm. A typical 180 degree bellcrank consists of a straight bar pivoted in the center. When one arm is pulled or pushed, the bar rotates around the pivot point, pulling or pushing on the other arm. Mechanical advantage Changing the length of the arms changes the mechanical advantage of the system. Many applications do not change the direction of motion but instead amplify a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft located within the engine block, held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cylin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Rod

In a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or (for steam locomotives) the driving wheels. Internal combustion engines, and in particular all current automobile engines, do not generally have piston rods. Instead they use trunk pistons, where the piston and crosshead are combined and so do not need a rod between them. The term ''piston rod'' has been used as a synonym for 'connecting rod' in the context of these engines. Engines with crossheads have piston rods. These include most steam locomotives and some large marine diesel engines. Steam engines The first single-acting beam engines, such as Newcomen's, had a single power stroke acting downwards. Rather than a piston rod, they used an iron chain. This could transmit a tensile force, but not a compression force pushing upwards. The piston was sealed in the cylinder around its rim but the top of the cylinder was open. Later, a rudimentary pist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Engine

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.''Thermodynamics: An Engineering Approach'' by Yunus A. Cengal and Michael A. Boles Common features in all types There may be one or more pistons. Each piston is inside a cylinder, into which a gas is intro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flywheel

A flywheel is a mechanical device which uses the conservation of angular momentum to store rotational energy; a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. In particular, assuming the flywheel's moment of inertia is constant (i.e., a flywheel with fixed mass and second moment of area revolving about some fixed axis) then the stored (rotational) energy is directly associated with the square of its rotational speed. Since a flywheel serves to store mechanical energy for later use, it is natural to consider it as a kinetic energy analogue of an electrical inductor. Once suitably abstracted, this shared principle of energy storage is described in the generalized concept of an accumulator. As with other types of accumulators, a flywheel inherently smooths sufficiently small deviations in the power output of a system, thereby effectively playing the role of a low-pass filter with respect to the mechanical velocity ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Triple-expansion Steam Engine

A compound steam engine unit is a type of steam engine where steam is expanded in two or more stages. A typical arrangement for a compound engine is that the steam is first expanded in a high-pressure ''(HP)'' cylinder, then having given up heat and losing pressure, it exhausts directly into one or more larger-volume low-pressure ''(LP)'' cylinders. Multiple-expansion engines employ additional cylinders, of progressively lower pressure, to extract further energy from the steam. Invented in 1781, this technique was first employed on a Cornish beam engine in 1804. Around 1850, compound engines were first introduced into Lancashire textile mills. Compound systems There are many compound systems and configurations, but there are two basic types, according to how HP and LP piston strokes are phased and hence whether the HP exhaust is able to pass directly from HP to LP ( Woolf compounds) or whether pressure fluctuation necessitates an intermediate "buffer" space in the form of a st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)