|

Lean IT

Lean IT is the extension of lean manufacturing and lean services principles to the development and management of information technology (IT) products and services. Its central concern, applied in the context of IT, is the elimination of waste, where ''waste'' is work that adds no value to a product or service. Although lean principles are generally well established and have broad applicability, their extension from manufacturing to IT is only just emerging. Lean IT poses significant challenges for practitioners while raising the promise of no less significant benefits. And whereas Lean IT initiatives can be limited in scope and deliver results quickly, implementing Lean IT is a continuing and long-term process that may take years before lean principles become intrinsic to an organization's culture. Extension to IT As lean manufacturing has become more widely implemented, the extension of lean principles is beginning to spread to IT (and other service industries).Hanna, Julia. ‚Brin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war 1950s and 1960s by the Japa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

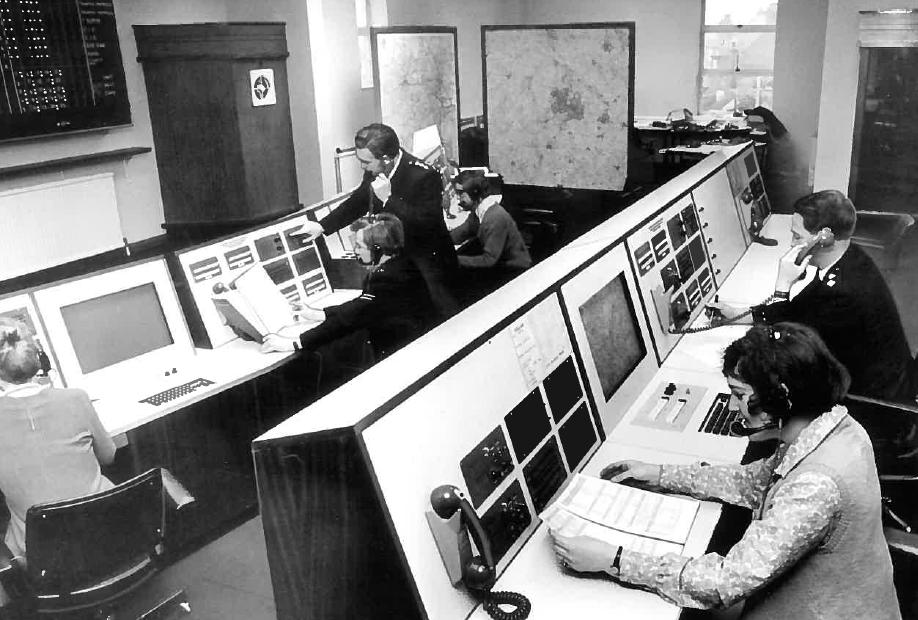

Call Center

A call centre ( Commonwealth spelling) or call center (American spelling; see spelling differences) is a managed capability that can be centralised or remote that is used for receiving or transmitting a large volume of enquiries by telephone. An inbound call centre is operated by a company to administer incoming product or service support or information enquiries from consumers. Outbound call centres are usually operated for sales purposes such as telemarketing, for solicitation of charitable or political donations, debt collection, market research, emergency notifications, and urgent/critical needs blood banks. A contact centre is a further extension to call centres telephony based capabilities, administers centralised handling of individual communications, including letters, faxes, live support software, social media, instant message, and email. A call center was previously seen to be an open workspace for call center agents, with workstations that include a computer and d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Provisioning

In telecommunication, provisioning involves the process of preparing and equipping a network to allow it to provide new services to its users. In National Security/Emergency Preparedness telecommunications services, ''"provisioning"'' equates to ''"initiation"'' and includes altering the state of an existing priority service or capability. The concept of network provisioning or service mediation, mostly used in the telecommunication industry, refers to the provisioning of the customer's services to the network elements, which are various equipment connected in that network communication system. Generally in telephony provisioning this is accomplished with network management database table mappings. It requires the existence of networking equipment and depends on network planning and design. In a modern signal infrastructure employing information technology (IT) at all levels, there is no possible distinction between telecommunications services and "higher level" infrastructure. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Just-in-time (business)

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war 1950s and 1960s by the Japanes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mura (Japanese Term)

is a Japanese word meaning "unevenness; irregularity; lack of uniformity; nonuniformity; inequality", and is a key concept in the Toyota Production System (TPS) as one of the three types of waste (''muda'', ''mura'', '' muri''). Waste in this context refers to the wasting of time or resources rather than wasteful by-products and should not be confused with Waste reduction. Toyota adopted these three Japanese words as part of their product improvement program, due to their familiarity in common usage. Mura, in terms of business/process improvement, is avoided through Just-In-Time systems which are based on keeping little or no inventory. These systems supply the production process with the right part, at the right time, in the right amount, using first-in, first-out (FIFO) component flow. Just-In-Time systems create a ‚Äúpull system‚ÄĚ in which each sub-process withdraws its needs from the preceding sub-processes, and ultimately from an outside supplier. When a preceding proces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Value Stream Mapping

Value-stream mapping, also known as "material- and information-flow mapping", is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer. A value stream map is a visual tool that displays all critical steps in a specific process and easily quantifies the time and volume taken at each stage. Value stream maps show the flow of both materials and information as they progress through the process. Whereas a value stream map represents a core business process that adds value to a material product, a value chain diagram shows an overview of all activities within a company. Other business activities may be represented in "value stream diagrams" and/or other kinds of diagram that represent business processes that create and use business data. Purpose The purpose of value-stream mapping is to identify and remove or reduce "waste" ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Value Stream Mapping

Value-stream mapping, also known as "material- and information-flow mapping", is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer. A value stream map is a visual tool that displays all critical steps in a specific process and easily quantifies the time and volume taken at each stage. Value stream maps show the flow of both materials and information as they progress through the process. Whereas a value stream map represents a core business process that adds value to a material product, a value chain diagram shows an overview of all activities within a company. Other business activities may be represented in "value stream diagrams" and/or other kinds of diagram that represent business processes that create and use business data. Purpose The purpose of value-stream mapping is to identify and remove or reduce "waste" ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Service Catalogue

A service catalog (or catalogue), is an organized and curated collection of any and all business and information technology related services that can be performed by, for, or within an enterprise. Service catalogs act as knowledge management tools for the employees and consultants of an enterprise, allowing them to route their requests for and about services and service-related topics to the subject matter experts who own, are accountable for, and operate them. Each service within such service catalogs is usually very repeatable and has controlled inputs, processes, and outputs. Service catalogs also allow leadership and management, for example the Chief Operations Officer (COO), to compartmentalize the enterprise into highly structured and more efficient operational units, hence the descriptive phrase: "''a service-oriented enterprise''." Service centralization A service catalog is a means of centralizing all services that are important to the stakeholders of the enterprises wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Backup

In information technology, a backup, or data backup is a copy of computer data taken and stored elsewhere so that it may be used to restore the original after a data loss event. The verb form, referring to the process of doing so, is "back up", whereas the noun and adjective form is " backup". Backups can be used to recover data after its loss from data deletion or corruption, or to recover data from an earlier time. Backups provide a simple form of disaster recovery; however not all backup systems are able to reconstitute a computer system or other complex configuration such as a computer cluster, active directory server, or database server. A backup system contains at least one copy of all data considered worth saving. The data storage requirements can be large. An information repository model may be used to provide structure to this storage. There are different types of data storage devices used for copying backups of data that is already in secondary storage onto archive fi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Application Performance Management

In the fields of information technology and systems management, application performance management (APM) is the monitoring and management of the performance and availability of software applications. APM strives to detect and diagnose complex application performance problems to maintain an expected level of service. APM is "the translation of IT metrics into business meaning ( .e.value)." Measuring application performance Two sets of performance metrics are closely monitored. The first set of performance metrics defines the performance experienced by end-users of the application. One example of performance is average response times under peak load. The components of the set include load and response times: :* The load is the volume of transactions processed by the application, e.g., transactions per second, requests per second, pages per second. Without being loaded by computer-based demands (e.g. searches, calculations, transmissions), most applications are fast enough, which ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Supply Chain Optimization

Supply-chain optimization (SCO) aims to ensure the optimal operation of a manufacturing and distribution of supply chain. This includes the optimal placement of inventory within the supply chain, minimizing operating costs including manufacturing costs, transportation costs, and distribution costs. Optimization often involves the application of mathematical modelling techniques using computer software. It is often considered to be part of supply chain engineering, although the latter is mainly focused on mathematical modelling approaches, whereas supply chain optimization can also be undertaken using qualitative, management based approaches. Applications Typically, supply-chain managers aim to maximize the profitable operation of their manufacturing and distribution supply chain. This could include measures like maximizing gross margin return on inventory invested (GMROII) (balancing the cost of inventory at all points in the supply chain with availability to the customer), min ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ecommerce

E-commerce (electronic commerce) is the activity of electronically buying or selling of products on online services or over the Internet. E-commerce draws on technologies such as mobile commerce, electronic funds transfer, supply chain management, Internet marketing, online transaction processing, electronic data interchange (EDI), inventory management systems, and automated data collection systems. E-commerce is in turn driven by the technological advances of the semiconductor industry, and is the largest sector of the electronics industry. Defining e-commerce The term was coined and first employed by Dr. Robert Jacobson, Principal Consultant to the California State Assembly's Utilities & Commerce Committee, in the title and text of California's Electronic Commerce Act, carried by the late Committee Chairwoman Gwen Moore (D-L.A.) and enacted in 1984. E-commerce typically uses the web for at least a part of a transaction's life cycle although it may also use other technolog ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |