|

Kar98k

The Karabiner 98 kurz (; "carbine 98 short"), often abbreviated Karabiner 98k, Kar98k or K98k and also sometimes incorrectly referred to as a K98 (a K98 is a Polish carbine and copy of the Kar98a), is a bolt-action rifle chambered for the 7.92×57mm Mauser cartridge. It was adopted on 21 June 1935 as the standard service rifle by the German ''Wehrmacht.''K98k Mauser Page Retrieved 28 March 2007. It was one of the final developments in the long line of military rifles. Although supplemented by semi-automatic and fully automatic rifles during World War II, the Karabiner 98k remained the primary German ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

German Military Rifles

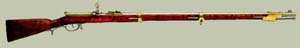

The evolution of German military rifles is a history of common and diverse paths followed by the separate German states, until the mid-19th century when Prussia emerged as the dominant state within Germany and the nation was unified. This article discusses rifled shoulder arms developed in or for the military of the states that later became Germany; it excludes firearms of the Austrian Empire, except where they were used substantially by German troops. There was also a period in the late 20th century when Germany was again divided and the two nations had separate armies and weapons, in "Cold War" opposition. The various rifles used during this period are displayed here, identified by either East German or West German usage. Early ''Jäger'' rifles ''Jäger'' (German, lit. "hunter") were a type of soldier, a form of light infantry, first named by the Landgrave of Hesse when he formed such a unit from his foresters and huntsmen in 1631. Huntsmen and foresters recruited in certain Ger ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mauser

Mauser, originally Königlich Württembergische Gewehrfabrik ("Royal Württemberg Rifle Factory"), was a German arms manufacturer. Their line of bolt-action rifles and semi-automatic pistols has been produced since the 1870s for the German armed forces. In the late 19th and early 20th centuries, Mauser designs were also exported and licensed to many countries which adopted them as military and civilian sporting firearms. The Gewehr 98 in particular was widely adopted and copied, and is the foundation of many of today's sporting bolt-action rifles. History King Frederick I founded the enterprise as Königliche Waffen Schmieden (literally: Royal Weapons Forges) on 31 July 1811. Originally located partly at Ludwigsburg and partly in Christophsthal, the factory transferred to the former Augustine Cloister in Oberndorf am Neckar, where Andreas Mauser worked as the master gunsmith. Of his seven sons who worked with him there, Peter Paul Mauser showed an outstanding ability to deve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbine

A carbine ( or ) is a long gun that has a barrel shortened from its original length. Most modern carbines are rifles that are compact versions of a longer rifle or are rifles chambered for less powerful cartridges. The smaller size and lighter weight of carbines make them easier to handle. They are typically issued to high-mobility troops such as special operations soldiers and paratroopers, as well as to mounted, artillery, logistics, or other non-infantry personnel whose roles do not require full-sized rifles, although there is a growing tendency for carbines to be issued to front-line soldiers to offset the increasing weight of other issued equipment. An example of this is the U.S. Army's M4 carbine, which is standard issue. Etymology The name comes from its first users — cavalry troopers called "carabiniers", from the French ''carabine'', from Old French ''carabin'' (soldier armed with a musket), whose origin is unclear. One theory connects it to an "ancient engine of w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Waffenamt

''Waffenamt'' (WaA) was the German Army Weapons Agency. It was the centre for research and development of the Weimar Republic and later the Third Reich for weapons, ammunition and army equipment to the German Reichswehr and then Wehrmacht The ''Wehrmacht'' (, ) were the unified armed forces of Nazi Germany from 1935 to 1945. It consisted of the ''Heer'' (army), the ''Kriegsmarine'' (navy) and the ''Luftwaffe'' (air force). The designation "''Wehrmacht''" replaced the previous .... It was founded 8 November 1919 as ''Reichwaffenamt'' (RWA), and 5 May 1922 the name was changed to ''Heereswaffenamt'' (HWA). The task of overseeing Germany's gigantic pre-World War II rearmament program was given to the ''Heeresabnahmestelle'' (the Army Acceptance Organization, commonly referred to as the ''Abnahme''), a subsidiary of the ''Heereswaffenamt''. By 1940 the ''Abnahme'' consisted of 25,000 personnel in five departments in 16 inspection areas, augmented by specially selected plan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron Sight

Iron sights are a system of physical alignment markers (usually made of metallic material) used as a sighting device to assist the accurate aiming of ranged weapons (such as a firearm, airgun, crossbow or even compound bow), or less commonly as a primitive finder sight for optical telescopes. The earliest sighting device, it relies completely on the viewer's naked eye (mostly under ambient lighting), and is distinctly different to optical sights such as telescopic sights, reflector (reflex) sights, holographic sights and laser sights, which make use of optical manipulation and/or active illumination, as well as the newer optoelectronics, which use digital imaging and even incorporate augmented reality. Iron sights are typically composed of two components mounted perpendicularly above the weapon's bore axis: a rear sight nearer (or ''proximally'') to the shooter's eye, and a front sight farther forward (or ''distally'') near the muzzle. During aiming, the shooter aligns his/ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Parkerizing

Phosphate conversion coating is a chemical treatment applied to steel parts that creates a thin adhering layer of iron, zinc, or manganese phosphates, to achieve corrosion resistance, lubrication, or as a foundation for subsequent coatings or painting. It is one of the most common types of conversion coating. The process is also called phosphate coating, phosphatization, phosphatizing, or phosphating. It is also known by the trade name Parkerizing, especially when applied to firearms and other military equipment. A phosphate coating is usually obtained by applying to the steel part a dilute solution of phosphoric acid, possibly with soluble iron, zinc, and/or manganese salts. The solution may be applied by sponging, spraying, or immersion. Phosphate conversion coatings can also be used on aluminium, zinc, cadmium, silver and tin. Types The main types of phosphate coatings are manganese, iron, and zinc. * Manganese phosphate coatings are used both for corrosion resistanc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phosphate Conversion Coating

Phosphate conversion coating is a chemical treatment applied to steel parts that creates a thin adhering layer of iron, zinc, or manganese phosphates, to achieve corrosion resistance, lubrication, or as a foundation for subsequent coatings or painting. It is one of the most common types of conversion coating. The process is also called phosphate coating, phosphatization, phosphatizing, or phosphating. It is also known by the trade name Parkerizing, especially when applied to firearms and other military equipment. A phosphate coating is usually obtained by applying to the steel part a dilute solution of phosphoric acid, possibly with soluble iron, zinc, and/or manganese salts. The solution may be applied by sponging, spraying, or immersion. Phosphate conversion coatings can also be used on aluminium, zinc, cadmium, silver and tin. Types The main types of phosphate coatings are manganese, iron, and zinc. * Manganese phosphate coatings are used both for corrosion resistance a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Galvanic Corrosion

Galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. A similar galvanic reaction is exploited in primary cells to generate a useful electrical voltage to power portable devices. This phenomenon is named after Italian physician Luigi Galvani (1737-1798). Overview Dissimilar metals and alloys have different electrode potentials, and when two or more come into contact in an electrolyte, one metal (that's more reactive) acts as anode and the other (that's less reactive) as cathode. The electropotential difference between the reactions at the two electrodes is the driving force for an accelerated attack on the anode metal, which dissolves into the electrolyte. This leads to the metal at the anode corroding more quickly than it otherwise would and corrosion at the cathode being inhibited. The presenc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Black Oxide

Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper and copper based alloys, zinc, powdered metals, and silver solder. It is used to add mild corrosion resistance, for appearance, and to minimize light reflection. To achieve maximal corrosion resistance the black oxide must be impregnated with oil or wax. One of its advantages over other coatings is its minimal buildup. Ferrous material A standard black oxide is magnetite (FeO), which is more mechanically stable on the surface and provides better corrosion protection than red oxide (rust) FeO. Modern industrial approaches to forming black oxide include the hot and mid-temperature processes described below. Traditional methods are described in the article on bluing. They are of interest historically, and are also useful for hobbyists to form black oxide safely with little equipment and without toxic chemicals. Low temperature oxide, also described below, is not a conversion coating� ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnetite

Magnetite is a mineral and one of the main iron ores, with the chemical formula Fe2+Fe3+2O4. It is one of the oxides of iron, and is ferrimagnetic; it is attracted to a magnet and can be magnetized to become a permanent magnet itself. With the exception of extremely rare native iron deposits, it is the most magnetic of all the naturally occurring minerals on Earth. Naturally magnetized pieces of magnetite, called lodestone, will attract small pieces of iron, which is how ancient peoples first discovered the property of magnetism. Magnetite is black or brownish-black with a metallic luster, has a Mohs hardness of 5–6 and leaves a black streak. Small grains of magnetite are very common in igneous and metamorphic rocks. The chemical IUPAC name is iron(II,III) oxide and the common chemical name is ''ferrous-ferric oxide''. Properties In addition to igneous rocks, magnetite also occurs in sedimentary rocks, including banded iron formations and in lake and marine sediments ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bluing (steel)

Bluing is a passivation process in which steel is partially protected against rust using a black oxide coating. It is named after the blue-black appearance of the resulting protective finish. Bluing involves an electrochemical conversion coating resulting from an oxidizing chemical reaction with iron on the surface selectively forming magnetite (), the black oxide of iron. In comparison, rust, the red oxide of iron (), undergoes an extremely large volume change upon hydration; as a result, the oxide easily flakes off causing the typical reddish rusting away of iron. Black oxide provides minimal protection against corrosion, unless also treated with a water-displacing oil to reduce wetting and galvanic action. In colloquial use, thin coatings of black oxide are often termed 'gun bluing', while heavier coatings are termed 'black oxide'. Both refer to the same chemical process for providing true gun bluing. Overview Various processes are used for the oxidizing process. "Cold ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Receiver (firearms)

In firearms terminology, the firearm frame or receiver is the part of a firearm which integrates other components by providing housing for internal action components such as the hammer, bolt or breechblock, firing pin and extractor, and has threaded interfaces for externally attaching ("receiving") components such as the barrel, stock, trigger mechanism and iron/optical sights. The receiver is often made of forged, machined, or stamped steel or aluminium; in addition to these traditional materials, modern science and engineering have introduced polymers and sintered metal powders to receiver construction. Mounting A barrel can be fixed to the receiver using barrel and receiver action threads or similar methods. In US law For the purposes of United States law, the receiver or frame is legally the firearm, and as such it is the controlled part. The definition of which assembly is the legal receiver varies from firearm to firearm, under US law. Generally, the law requ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)