|

Just In Case

Just-in-case manufacturing (JIC) is a term sometimes applied to traditional manufacturing systems used before the influence of modern technologies and newer transportation infrastructures. It is the contrary in many ways to the recently evolved Just In Time manufacturing system. Operation In JIC, manufacturers need to maintain large inventories of supplies, parts, warehousing resources, and extra workers to meet production contingencies. These contingencies, more common in less industrialized countries, can be poor transportation infrastructure, poor quality control, vulnerability to other suppliers' production problems, and natural disasters. These supply-chain instabilities could lead to costly production inefficiencies therefore a manufacturer may maintain and pay for excess inventory and backups of "fragile" production stages which could get out of sync, cause production shutdowns, or create supply-chain delays for other manufacturers. In JIC, manufacturers reorder stoc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Just-in-Time Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war In Western usage, the ph ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Just In Time Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war 1950s and 1960s by the Japan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed into a final p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Modern Technology

Technology is the application of knowledge to reach practical goals in a specifiable and reproducible way. The word ''technology'' may also mean the product of such an endeavor. The use of technology is widely prevalent in medicine, science, industry, communication, transportation, and daily life. Technologies include physical objects like utensils or machines and intangible tools such as software. Many technological advancements have led to societal changes. The earliest known technology is the stone tool, used in the prehistoric era, followed by fire use, which contributed to the growth of the human brain and the development of language in the Ice Age. The invention of the wheel in the Bronze Age enabled wider travel and the creation of more complex machines. Recent technological developments, including the printing press, the telephone, and the Internet have lowered communication barriers and ushered in the knowledge economy. While technology contributes to econom ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transportation Infrastructure

Transport (in British English), or transportation (in American English), is the intentional movement of humans, animals, and goods from one location to another. Modes of transport include air, land (rail and road), water, cable, pipeline, and space. The field can be divided into infrastructure, vehicles, and business operations, operations. Transport enables human trade, which is essential for the development of civilizations. Transport infrastructure consists of both fixed installations, including roads, railways, airway (aviation), airways, waterways, canals, and pipeline transport, pipelines, and terminals such as airports, train station, railway stations, bus stations, warehouses, trucking terminals, refueling depots (including fueling docks and fuel stations), and seaports. Terminals may be used both for interchange of passengers and cargo and for maintenance. Means of transport are any of the different kinds of transport facilities used to carry people or cargo. They ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inventory

Inventory (American English) or stock (British English) refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation. Inventory management is a discipline primarily about specifying the shape and placement of stocked goods. It is required at different locations within a facility or within many locations of a supply network to precede the regular and planned course of production and stock of materials. The concept of inventory, stock or work in process (or work in progress) has been extended from manufacturing systems to service businesses and projects, by generalizing the definition to be "all work within the process of production—all work that is or has occurred prior to the completion of production". In the context of a manufacturing production system, inventory refers to all work that has occurred—raw materials, partially finished products, finished products prior to sale and departure from the manufacturing system. I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Warehousing

A warehouse is a building for storing goods. Warehouses are used by manufacturers, importers, exporters, wholesalers, transport businesses, customs, etc. They are usually large plain buildings in industrial parks on the outskirts of cities, towns, or villages. Warehouses usually have loading docks to load and unload goods from trucks. Sometimes warehouses are designed for the loading and unloading of goods directly from railways, airports, or seaports. They often have cranes and forklifts for moving goods, which are usually placed on ISO standard pallets and then loaded into pallet racks. Stored goods can include any raw materials, packing materials, spare parts, components, or finished goods associated with agriculture, manufacturing, and production. In India and Hong Kong, a warehouse may be referred to as a "godown". There are also godowns in the Shanghai Bund. History Prehistory and ancient history A warehouse can be defined functionally as a building in which to store b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quality Control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements". This approach places emphasis on three aspects (enshrined in standards such as ISO 9001): # Elements such as controls, job management, defined and well managed processes, performance and integrity criteria, and identification of records # Competence, such as knowledge, skills, experience, and qualifications # Soft elements, such as personnel, integrity, confidence, organizational culture, motivation, team spirit, and quality relationships. Inspection is a major component of quality control, where physical product is examined visually (or the end results of a service are analyzed). Product inspectors will be provided with lists and descriptions of unacceptable product defects such as cracks or surface blemishes for example. History and introduction Ea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

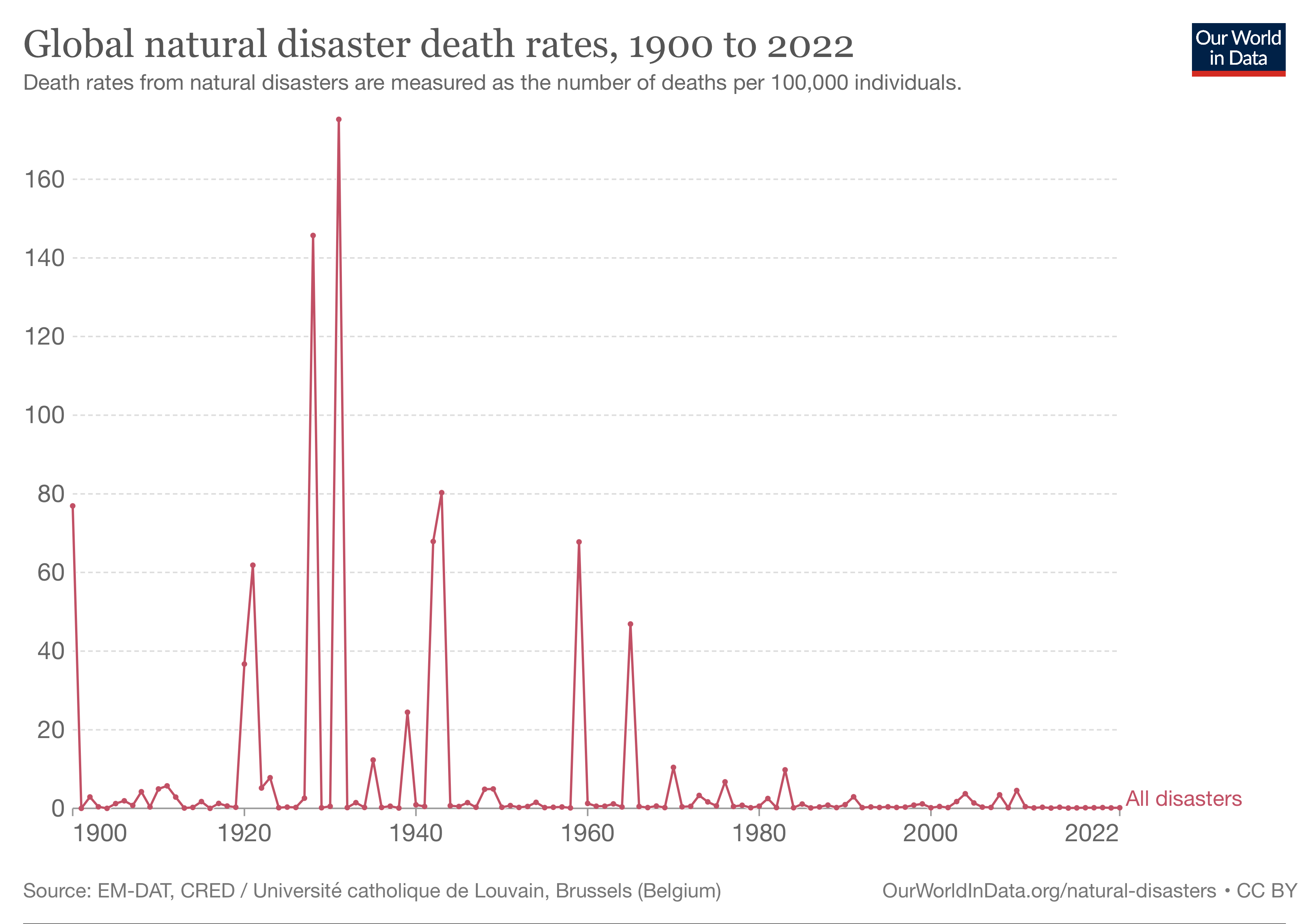

Natural Disasters

A natural disaster is "the negative impact following an actual occurrence of natural hazard in the event that it significantly harms a community". A natural disaster can cause loss of life or damage property, and typically leaves some economic damage in its wake. The severity of the damage depends on the affected population's resilience and on the infrastructure available. Examples of natural hazards include: avalanche, coastal flooding, cold wave, drought, earthquake, hail, heat wave, hurricane (tropical cyclone), ice storm, landslide, lightning, riverine flooding, strong wind, tornado, typhoon, tsunami, volcanic activity, wildfire, winter weather. In modern times, the divide between natural, man-made and man-accelerated disasters is quite difficult to draw. Human choices and activities like architecture, fire, resource management or even climate change potentially play a role in causing "natural disasters". In fact, the term "natural disaster" has been called a misnomer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Supply-chain

In commerce, a supply chain is a network of facilities that procure raw materials, transform them into intermediate goods and then final products to customers through a distribution system. It refers to the network of organizations, people, activities, information, and resources involved in delivering a product or service to a consumer. Supply chain activities involve the transformation of natural resources, raw materials, and components into a finished product and delivering the same to the end customer. In sophisticated supply chain systems, used products may re-enter the supply chain at any point where residual value is recyclable. Supply chains link value chains. Suppliers in a supply chain are often ranked by "tier", with first-tier suppliers supplying directly to the client, second-tier suppliers supplying to the first tier, and so on. Overview A typical supply chain begins with the ecological, biological, and political regulation of natural resources, followed by the h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead Time

A lead time is the latency between the initiation and completion of a process. For example, the lead time between the placement of an order and delivery of new cars by a given manufacturer might be between 2 weeks and 6 months, depending on various particularities. One business dictionary defines "manufacturing lead time" as the total time required to manufacture an item, including order preparation time, queue time, setup time, run time, move time, inspection time, and put-away time. For make-to-order products, it is the time between release of an order and the production and shipment that fulfill that order. For make-to-stock products, it is the time taken from the release of an order to production and receipt into finished goods inventory. Supply chain management A conventional definition of lead time in a supply chain management context is the time from the moment the customer places an order (the moment the supplier learns of the requirement) to the moment it is ready for de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resilience (engineering And Construction)

In the fields of engineering and construction, resilience is the ability to absorb or avoid damage without suffering complete failure and is an objective of design, maintenance and restoration for buildings and infrastructure, as well as communities. A more comprehensive definition is that it is the ability to respond, absorb, and adapt to, as well as recover in a disruptive event. A resilient structure/system/community is expected to be able to resist to an extreme event with minimal damages and functionality disruptions during the event; after the event, it should be able to rapidly recovery its functionality similar to or even better than the pre-event level. The concept of resilience originated from engineering and then gradually applied to other fields. It is related to that of vulnerability. Both terms are specific to the event perturbation, meaning that a system/infrastructure/community may be more vulnerable or less resilient to one event than another one. However, they are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |