|

Industrial Finishing

Industrial finishing is any kind of secondary process done to any metal, plastic, or wood product used in a common market such as automotive, Original Equipment Manufacturer, OEM, telecommunications or point-of-purchase. The most common commodity in the industrial finishing market is plastic parts. These can be injection molded, thermoformed, extruded or vacuum formed. Most parts are painted but can be Pad printing, pad printed or silkscreening, silkscreened. One finishing process is vacuum metalising. See also *Surface finishing Coatings Metalworking {{Metalworking-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Original Equipment Manufacturer

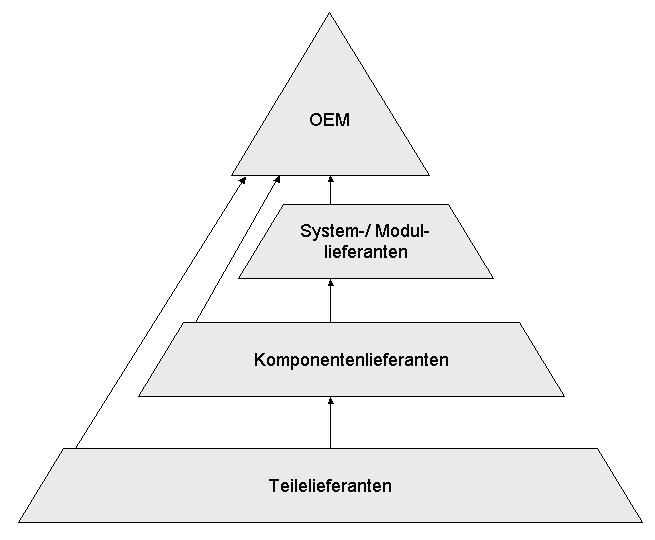

An original equipment manufacturer (OEM) is generally perceived as a company that produces non-aftermarket parts and equipment that may be marketed by another manufacturer. It is a common industry term recognized and used by many professional organizations such as SAE International, ISO, and others. However, the term is also used in several other ways, which causes ambiguity. It sometimes means the maker of a system that includes other companies' subsystems, an end-product producer, an automotive part that is manufactured by the same company that produced the original part used in the automobile's assembly, or a value-added reseller.Ken Olsen: PDP-1 and PDP-8 (page 3) , economicadventure.com Automotive parts When referring to auto parts, OEM refers to the manufactur ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pad Printing

Pad printing (also called tampography) is a printing process that can transfer a 2-D image onto a 3-D object (e.g. a ceramic pottery). This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the cliché via a silicone pad onto a substrate. Pad printing is used for printing on otherwise difficult to print on products in many industries including medical, automotive, promotional, apparel, and electronic objects, as well as appliances, sports equipment and toys. It can also be used to deposit functional materials such as conductive inks, adhesives, dyes and lubricants. Physical changes within the ink film both on the cliché and on the pad allow it to leave the etched image area in favor of adhering to the pad, and to subsequently release from the pad in favor of adhering to the substrate. The unique properties of the silicone pad enable it to pick the image up from a flat plane and transfer it to a variety of surfa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silkscreening

Screen printing is a printing technique where a mesh is used to transfer ink (or dye) onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed. One colour is printed at a time, so several screens can be used to produce a multi-coloured image or design. Traditionally, silk was used in the process. Currently, synthetic threads are commonly used in the screen printing process. The most popular mesh in general use is made of polyester. There are special-use mesh materials of nylon and stainless steel available to the screen-printer. There are also different types of mesh size which will determine the outcome and look of the fini ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum Metalising

Vacuum deposition is a group of processes used to deposit layers of material atom-by-atom or molecule-by-molecule on a solid surface. These processes operate at pressures well below atmospheric pressure (i.e., vacuum). The deposited layers can range from a thickness of one atom up to millimeters, forming freestanding structures. Multiple layers of different materials can be used, for example to form optical coatings. The process can be qualified based on the vapor source; physical vapor deposition uses a liquid or solid source and chemical vapor deposition uses a chemical vapor. Description The vacuum environment may serve one or more purposes: * reducing the particle density so that the mean free path for collision is long * reducing the particle density of undesirable atoms and molecules (contaminants) * providing a low pressure plasma environment * providing a means for controlling gas and vapor composition * providing a means for mass flow control into the processing chambe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Finishing

Surface finishing is a broad range of industrial processes that alter the surface of a manufactured item to achieve a certain property. Finishing processes may be employed to: improve appearance, adhesion or wettability, solderability, corrosion resistance, tarnish resistance, chemical resistance, wear resistance, hardness, modify electrical conductivity, remove burrs and other surface flaws, and control the surface friction.. In limited cases some of these techniques can be used to restore original dimensions to salvage or repair an item. An unfinished surface is often called '' mill finish''. Surface finishing processes can be categorized by how they affect the workpiece: *Removing or reshaping finishing *Adding or altering finishing Mechanical processes may also be categorized together because of similarities the final surface finish. Adding and altering *Blanching * Burnishing * Calendering *Case hardening *Ceramic glaze *Cladding *Corona treatment *Diffusion processes: **C ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coatings

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. Powder coatings. Paints and lacquers are coatings that mostly have dual uses of protecting the substrate and being decorative, although some artists paints are only for decoration, and the paint on large industrial pipes is for preventing corrosion and identification e.g. blue for process water, red for fire-fighting control etc. Functional coatings may be applied to change the surface properties of the substrate, such as adhesion, wettability, corrosion resistance, or wear resistance. In other cases, e.g. semiconductor device fabrication (where the substrate is a wafer), the coating adds a completely new property, such as a magnetic response or electrical conductivity, and forms an essential part of the finished product. A major consideratio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |