|

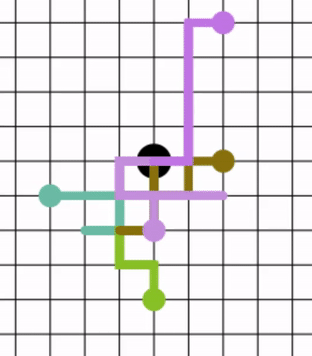

Island Growth

Island growth is a physical model of deposited film growth and chemical vapor deposition. Introduction When atoms are deposited slowly onto a flat surface, the first one undergoes a random walk on that surface. Eventually a second atom is deposited; in all likelihood it will eventually meet the first atom. Once the two atoms meet they may bond to form a particle with a higher mass and a lower random walk velocity. Because the bonded particles are now more stable and less mobile than before, they are called an "island." Subsequent atoms deposited on the substrate eventually meet and bond with the island, further increasing its size and stability. Eventually the island can grow to fill the entire substrate with a single large grain. The faster the atoms are deposited, the greater amount of atoms on the substrate before any large stable islands form. As these atoms meet, they will bond to their local neighbors before having the chance to migrate to a distant island. In this way ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Vapor Deposition

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films. In typical CVD, the wafer (substrate) is exposed to one or more volatile precursors, which react and/or decompose on the substrate surface to produce the desired deposit. Frequently, volatile by-products are also produced, which are removed by gas flow through the reaction chamber. Microfabrication processes widely use CVD to deposit materials in various forms, including: monocrystalline, polycrystalline, amorphous, and epitaxial. These materials include: silicon (dioxide, carbide, nitride, oxynitride), carbon (fiber, nanofibers, nanotubes, diamond and graphene), fluorocarbons, filaments, tungsten, titanium nitride and various high-κ dielectrics. The term ''chemical vapour deposition'' was coined 1960 by ''John M. Blocher, Jr.'' who intended to differentia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Atoms

Every atom is composed of a nucleus and one or more electrons bound to the nucleus. The nucleus is made of one or more protons and a number of neutrons. Only the most common variety of hydrogen has no neutrons. Every solid, liquid, gas, and plasma is composed of neutral or ionized atoms. Atoms are extremely small, typically around 100 picometers across. They are so small that accurately predicting their behavior using classical physics, as if they were tennis balls for example, is not possible due to quantum effects. More than 99.94% of an atom's mass is in the nucleus. The protons have a positive electric charge, the electrons have a negative electric charge, and the neutrons have no electric charge. If the number of protons and electrons are equal, then the atom is electrically neutral. If an atom has more or fewer electrons than protons, then it has an overall negative or positive charge, respectively – such atoms are called ions. The electrons of an a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Substrate (materials Science)

Substrate is a term used in materials science and engineering to describe the base material on which processing is conducted. This surface could be used to produce new film or layers of material such as deposited coatings. It could be the base to which paint, adhesives, or adhesive tape is bonded. A typical substrate might be rigid such as metal, concrete, or glass, onto which a coating might be deposited. Flexible substrates are also used. With all coating processes, the condition of the surface of the substrate can strongly affect the bond of subsequent layers. This can include cleanliness, smoothness, surface energy, moisture, etc. Some substrates are anisotropic with surface properties being different depending on the direction: examples include wood and paper products. Coatings Coating can be by a variety of processes: * Adhesives and Adhesive tapes * Coating and printing processes * Chemical vapor deposition and physical vapor deposition * Conversion coating :* ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Random Walk

In mathematics, a random walk is a random process that describes a path that consists of a succession of random steps on some mathematical space. An elementary example of a random walk is the random walk on the integer number line \mathbb Z which starts at 0, and at each step moves +1 or −1 with equal probability. Other examples include the path traced by a molecule as it travels in a liquid or a gas (see Brownian motion), the search path of a foraging animal, or the price of a fluctuating stock and the financial status of a gambler. Random walks have applications to engineering and many scientific fields including ecology, psychology, computer science, physics, chemistry, biology, economics, and sociology. The term ''random walk'' was first introduced by Karl Pearson in 1905. Lattice random walk A popular random walk model is that of a random walk on a regular lattice, where at each step the location jumps to another site according to some probability distribution. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sputter Deposition

Sputter deposition is a physical vapor deposition (PVD) method of thin film deposition by the phenomenon of sputtering. This involves ejecting material from a "target" that is a source onto a "substrate" such as a silicon wafer. Resputtering is re-emission of the deposited material during the deposition process by ion or atom bombardment. Sputtered atoms ejected from the target have a wide energy distribution, typically up to tens of eV (100,000 K). The sputtered ions (typically only a small fraction of the ejected particles are ionized — on the order of 1 percent) can ballistically fly from the target in straight lines and impact energetically on the substrates or vacuum chamber (causing resputtering). Alternatively, at higher gas pressures, the ions collide with the gas atoms that act as a moderator and move diffusively, reaching the substrates or vacuum chamber wall and condensing after undergoing a random walk. The entire range from high-energy ballistic impact to low-en ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molecular Beam Epitaxy

Molecular-beam epitaxy (MBE) is an epitaxy method for thin-film deposition of single crystals. MBE is widely used in the manufacture of semiconductor devices, including transistors, and it is considered one of the fundamental tools for the development of nanotechnologies. MBE is used to fabricate diodes and MOSFETs (MOS field-effect transistors) at microwave frequencies, and to manufacture the lasers used to read optical discs (such as CDs and DVDs). History Original ideas of MBE process were first established by Günther. Films he deposited were not epitaxial, but were deposited on glass substrates. With the development of vacuum technology, MBE process was demonstrated by Davey and Pankey who succeeded in growing GaAs epitaxial films on single crystal GaAs substrates using Günther's method. Major subsequent development of MBE films was enabled by J.R. Arthur's investigations of kinetic behavior of growth mechanisms and Alfred Y. Cho's in situ observation of MBE process ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stranski–Krastanov Growth

Stranski–Krastanov growth (SK growth, also Stransky–Krastanov or Stranski–Krastanow) is one of the three primary modes by which thin films grow epitaxially at a crystal surface or interface. Also known as 'layer-plus-island growth', the SK mode follows a two step process: initially, complete films of adsorbates, up to several monolayers thick, grow in a layer-by-layer fashion on a crystal substrate. Beyond a critical layer thickness, which depends on strain and the chemical potential of the deposited film, growth continues through the nucleation and coalescence of adsorbate 'islands'. This growth mechanism was first noted by Ivan Stranski and Lyubomir Krastanov in 1938. It wasn't until 1958 however, in a seminal work by Ernst Bauer published in ''Zeitschrift für Kristallographie'', that the SK, Volmer–Weber, and Frank–van der Merwe mechanisms were systematically classified as the primary thin-film growth processes. Since then, SK growth has been the subject of inten ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |