|

Industrial Fans

Industrial fans and blowers are machines whose primary function is to provide and accommodate a large flow of air or gas to various parts of a building or other structures. This is achieved by rotating a number of blades, connected to a hub and shaft, and driven by a motor or turbine. The flow rates of these mechanical fans range from approximately to per minute. A blower is another name for a fan that operates where the resistance to the flow is primarily on the downstream side of the fan. Functions and industries There are many uses for the continuous flow of air or gas that industrial fans generate, including combustion, ventilation, aeration, particulate transport, exhaust, cooling, air-cleaning, and drying, to name a few. The industries served include electrical power production, pollution control, metal manufacturing and processing, cement production, mining, petrochemical, food processing, cryogenics, and clean rooms. Centrifugal fans and axial fans Most industrial f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating electrical power when combined with a generator.Munson, Bruce Roy, T. H. Okiishi, and Wade W. Huebsch. "Turbomachines." Fundamentals of Fluid Mechanics. 6th ed. Hoboken, NJ: J. Wiley & Sons, 2009. Print. A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor. Early turbine examples are windmills and waterwheels. Gas, steam, and water turbines have a casing around the blades that contains and controls the working fluid. Credit for invention of the steam turbine is given both to Anglo-Irish engineer Sir Charles Parsons (1854–1931) for invention of the reaction turbine, and to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clean Room

A cleanroom or clean room is an engineered space, which maintains a very low concentration of airborne particulates. It is well isolated, well-controlled from contamination, and actively cleansed. Such rooms are commonly needed for scientific research, and in industrial production for all nanoscale processes, such as semiconductor manufacturing. A cleanroom is designed to keep everything from dust, to airborne organisms, or vaporised particles, away from it, and so from whatever material is being handled inside it. The other way around, a cleanroom can also help keep materials escaping from it. This is often the primary aim in hazardous biology and nuclear work, in pharmaceutics and in virology. Cleanrooms typically come with a cleanliness level quantified by the number of particles per cubic meter at a predetermined molecule measure. The ambient outdoor air in a typical urban area contains 35,000,000 particles for each cubic meter in the size range 0.5 μm and bigger, eq ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Three-dimensional Losses And Correlation In Turbomachinery

Three-dimension losses and correlation in turbomachinery refers to the measurement of flow-fields in three dimensions, where measuring the loss of smoothness of flow, and resulting inefficiencies, becomes difficult, unlike two-dimensional losses where mathematical complexity is substantially less. Three-dimensionality takes into account large pressure gradients in every direction, design/curvature of blades, shock waves, heat transfer, cavitation, and viscous effects, which generate secondary flow, vortices, tip leakage vortices, and other effects that interrupt smooth flow and cause loss of efficiency. Viscous effects in turbomachinery block flow by the formation of viscous layers around blade profiles, which affects pressure rise and fall and reduces the effective area of a flow field. Interaction between these effects increases rotor instability and decreases the efficiency of turbomachinery. In calculating three-dimensional losses, every element affecting a flow path is taken ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Specific Fan Power

Specific Fan Power (SFP) is a parameter that quantifies the energy-efficiency of fan air movement systems. It is a measure of the electric power that is needed to drive a fan (or collection of fans), relative to the amount of air that is circulated through the fan(s). It is not constant for a given fan, but changes with both air flow rate and fan pressure rise. Definition SFP for a given fan system and operating point (combination of flow rate and pressure rise) is defined as: :SFP = where: * is the electrical power used by the fan (or sum of all fans in the ventilation system) W* is the gross amount of air circulated through the fan (or ventilation system) 3/s There are various sub-definitions of SFP for different specific applications, including SFPe (building energy performance calculations), SFPv (for performance verification tests), SFPi (individual fan), SFPAHU (air handling unit), SFPFCU (fan coil unit), and SFPBLDG (whole building). These are explained in and in part ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Axial Fan Design

An axial fan is a type of fan that causes gas to flow through it in an axial direction, parallel to the shaft about which the blades rotate. The flow is axial at entry and exit. The fan is designed to produce a pressure difference, and hence force, to cause a flow through the fan. Factors which determine the performance of the fan include the number and shape of the blades. Fans have many applications including in wind tunnels and cooling towers. Design parameters include power, flow rate, pressure rise and efficiency. Axial fans generally comprise fewer blades (two to six) than ducted fans. Axial fans commonly have larger radius and lower speed (ω) than ducted fans (esp. at similar power. Stress proportional to r^2). Calculation of parameters Since the calculation cannot be done using the inlet and outlet velocity triangles, which is not the case in other turbomachines, calculation is done by considering a mean velocity triangle for flow only through an infinitesimal blad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fan (mechanical)

A fan is a powered machine used to create a flow of air. A fan consists of a rotating arrangement of vanes or blades, generally made of wood, plastic, or metal, which act on the air. The rotating assembly of blades and hub is known as an ''impeller'', ''rotor'', or ''runner''. Usually, it is contained within some form of housing, or case. This may direct the airflow, or increase safety by preventing objects from contacting the fan blades. Most fans are powered by electric motors, but other sources of power may be used, including hydraulic motors, handcranks, and internal combustion engines. Mechanically, a fan can be any revolving vane, or vanes used for producing currents of air. Fans produce air flows with high volume and low pressure (although higher than ambient pressure), as opposed to compressors which produce high pressures at a comparatively low volume. A fan blade will often rotate when exposed to an air-fluid stream, and devices that take advantage of this, such as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Variable Speed Drive

Motor drive means a system that includes a motor. An adjustable speed motor drive means a system that includes a motor that has multiple operating speeds. A variable speed motor drive is a system that includes a motor and is continuously variable in speed. If the motor is generating electrical energy rather than using it – this could be called a generator drive but is often still referred to as a motor drive. A Variable Frequency Drive(VFD) or Variable Speed Drive(VSD) describes the electronic portion of the system that controls the speed of the motor. More generally, the term drive, describes equipment used to control the speed of machinery. Many industrial processes such as assembly lines must operate at different speeds for different products. Where process conditions demand adjustment of flow from a pump or fan, varying the speed of the drive may save energy compared with other techniques for flow control. Where speeds may be selected from several different pre-set ran ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tungsten Carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, cutting tools, chisels, abrasives, armor-piercing shells and jewelry. Tungsten carbide is approximately twice as stiff as steel, with a Young's modulus of approximately 530–700 GPa, and is double the density of steel—nearly midway between that of lead and gold. It is comparable with corundum (α-) in hardness and can be polished and finished only with abrasives of superior hardness such as cubic boron nitride and diamond powder, wheels and compounds. Naming Historically referred to as Wolfram, ''Wolf Rahm'', wolframite ore was then later carburized and cemented with a binder creating a composite now called "tungsten carbide". Tungsten is Swedish for "heavy stone". Col ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resource Recovery

Resource recovery is using wastes as an input material to create valuable products as new outputs. The aim is to reduce the amount of waste generated, thereby reducing the need for landfill space, and optimising the values created from waste. Resource recovery delays the need to use raw materials in the manufacturing process. Materials found in municipal solid waste, construction and demolition waste, commercial waste and industrial wastes can be used to recover resources for the manufacturing of new materials and products. Plastic, paper, aluminium, glass and metal are examples of where value can be found in waste. Resource recovery goes further than just the management of waste. Resource recovery is part of a circular economy, in which the extraction of natural resources and generation of wastes are minimised, and in which materials and products are designed more sustainably for durability, reuse, repairability, remanufacturing and recycling. Life-cycle analysis (LCA) can be use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Foil

An airfoil (American English) or aerofoil (British English) is the cross-sectional shape of an object whose motion through a gas is capable of generating significant lift, such as a wing, a sail, or the blades of propeller, rotor, or turbine. A solid body moving through a fluid produces an aerodynamic force. The component of this force perpendicular to the relative freestream velocity is called lift. The component parallel to the relative freestream velocity is called drag. An airfoil is a streamlined shape that is capable of generating significantly more lift than drag. Airfoils can be designed for use at different speeds by modifying their geometry: those for subsonic flight generally have a rounded leading edge, while those designed for supersonic flight tend to be slimmer with a sharp leading edge. All have a sharp trailing edge. Foils of similar function designed with water as the working fluid are called hydrofoils. The lift on an airfoil is primarily the result ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Movement And Control Association

The Air Movement and Control Association International, Inc. (AMCA) is an American trade body that sets standards for Heating, Ventilation and Air Conditioning (HVAC) equipment. It rates fan balance and vibration, aerodynamic performance, air density, speed and efficiency. AMCA was formed in 1955 from several earlier trade associations which could be traced back to the fan-testing requirements of the US Navy in 1923. It is a nonprofit organization that issues over 60 publications and standards, including testing methods, a Certified Ratings Program (CRP), application guides, educational texts, and safety guides. Membership and Activities AMCA membership is open to any company that manufactures or holds the design of a product that falls under the AMCA scope. AMCA publications and standards are developed when sufficient interest has been expressed by AMCA members. Publication and standard writing committees are composed of volunteers, which include both AMCA members and intereste ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

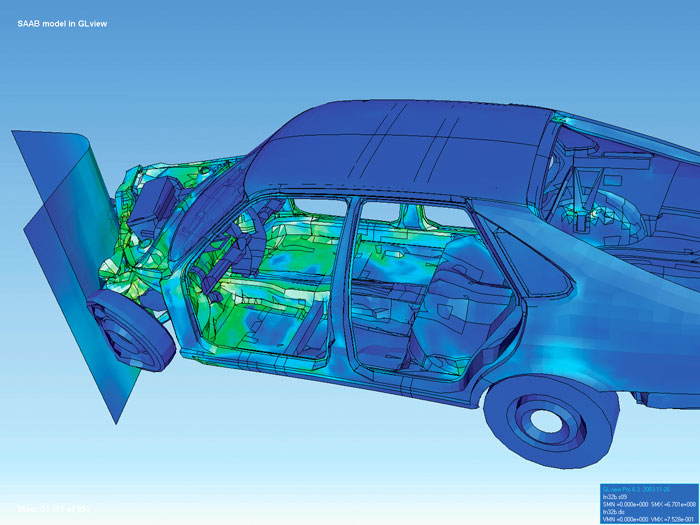

Finite Element Analysis

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The FEM is a general numerical method for solving partial differential equations in two or three space variables (i.e., some boundary value problems). To solve a problem, the FEM subdivides a large system into smaller, simpler parts that are called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numerical domain for the solution, which has a finite number of points. The finite element method formulation of a boundary value problem finally results in a system of algebraic equations. The method approximates the unknown function over the domain. The sim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |