|

Industrial And Manufacturing Engineering

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations. Industrial engineers use specialized knowledge and skills in the mathematical, physical and social sciences, together with the principles and methods of engineering analysis and design, to specify, predict, and evaluate the results obtained from systems and processes.Salvendy, Gabriel. Handbook of Industrial Engineering. John Wiley & Sons, Inc; 3rd edition p. 5 There are several industrial engineering principles followed in the manufacturing industry to ensure the effective flow of the systems, processes and operations. This includes Lean Manufacturing, Six Sigma, Information Systems, Process Capability and Define, Measure, Analyze, Improve and Control (DMAIC). Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Engineer Working

Industrial may refer to: Industry * Industrial archaeology, the study of the history of the industry * Industrial engineering, engineering dealing with the optimization of complex industrial processes or systems * Industrial city, a city dominated by one or more industries * Industrial loan company, a financial institution in the United States that lends money, and may be owned by non-financial institutions * Industrial organization, a field that builds on the theory of the firm by examining the structure and boundaries between firms and markets * Industrial Revolution, the development of industry in the 18th and 19th centuries * Industrial society, a society that has undergone industrialization * Industrial technology, a broad field that includes designing, building, optimizing, managing and operating industrial equipment, and predesignated as acceptable for industrial uses, like factories * Industrial video, a video that targets “industry” as its primary audience * Industrial ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital. The manufacturing or production engineer's primary focus is to turn raw material into an updated or new product in the most effective, efficient & economic way possible. An example would be a company uses computer integrated technology in order for them to produce their product so that it is faster and uses less human labor. Overview Manufacturing Engineering is based on core industrial engineering and mechanical engineering skills, adding important elements from mechatronics, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Economies Of Scale

In microeconomics, economies of scale are the cost advantages that enterprises obtain due to their scale of operation, and are typically measured by the amount of output produced per unit of time. A decrease in cost per unit of output enables an increase in scale. At the basis of economies of scale, there may be technical, statistical, organizational or related factors to the degree of market control. This is just a partial description of the concept. Economies of scale apply to a variety of the organizational and business situations and at various levels, such as a production, plant or an entire enterprise. When average costs start falling as output increases, then economies of scale occur. Some economies of scale, such as capital cost of manufacturing facilities and friction loss of transportation and industrial equipment, have a physical or engineering basis. The economic concept dates back to Adam Smith and the idea of obtaining larger production returns through the use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

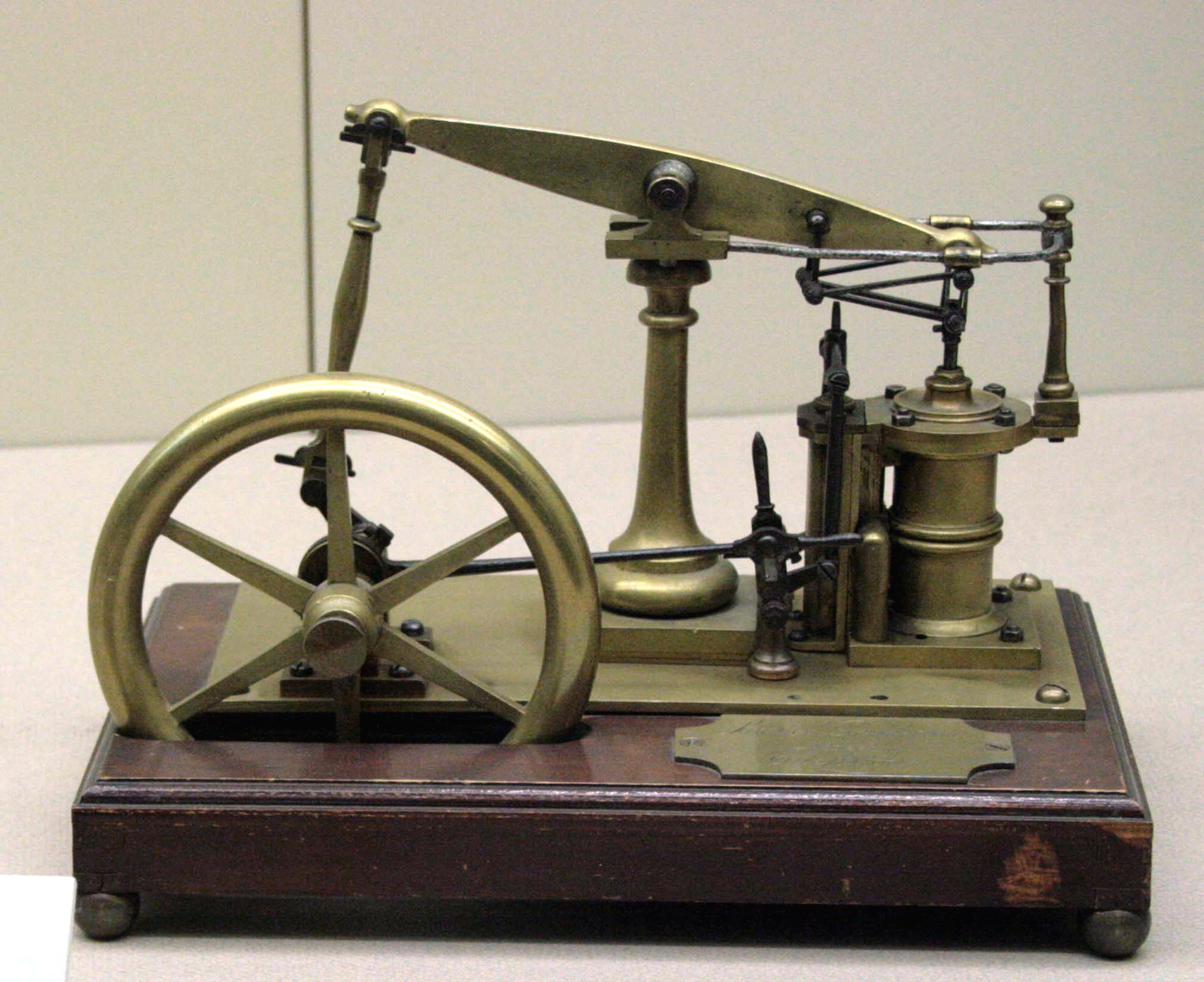

Steam Engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and crank, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term ''steam engine'' can refer to either complete steam plants (including boilers etc.), such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine. Although steam-driven devices were known as early as the aeolipile in the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

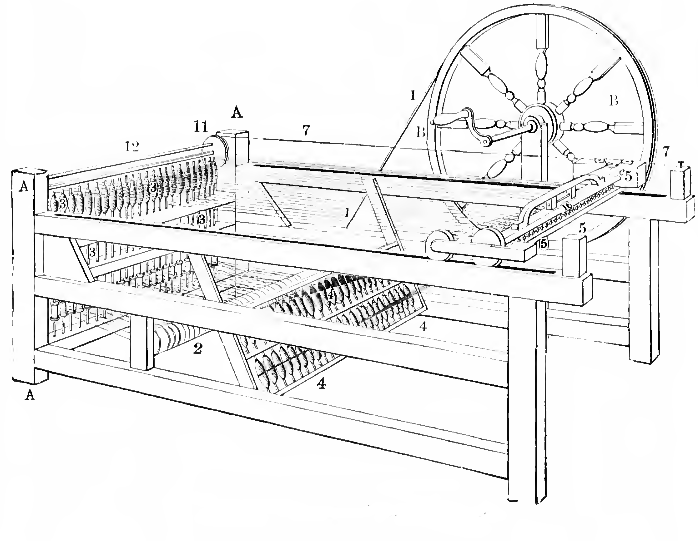

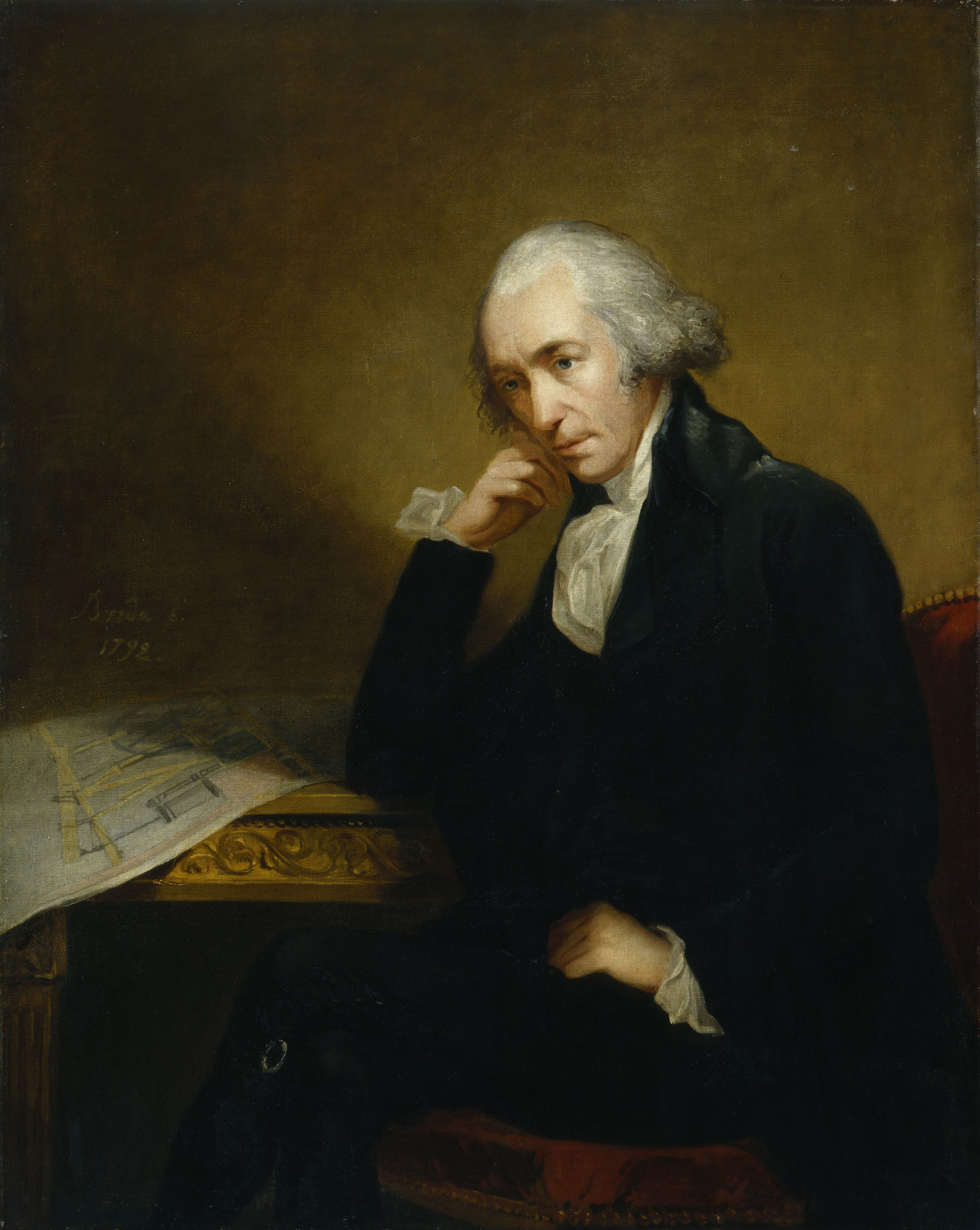

Spinning Jenny

The spinning jenny is a multi-spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Stanhill, Oswaldtwistle, Lancashire in England. The device reduced the amount of work needed to produce cloth, with a worker able to work eight or more spools at once. This grew to 120 as technology advanced. The yarn produced by the jenny was not very strong until Richard Arkwright invented the water-powered water frame. The spinning jenny helped to start the factory system of cotton manufacturing. History The spinning jenny was invented by James Hargreaves. He was born in Oswaldtwistle, near Blackburn, around 1720. Blackburn was a town with a population of about 5,000, known for the production of "Blackburn greys," cloths of linen warp and cotton weft initially imported from India. They were usually sent to London to be printed. At the time, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flying Shuttle

The flying shuttle was one of the key developments in the industrialization of weaving during the early Industrial Revolution. It allowed a single weaver to weave much wider fabrics, and it could be mechanized, allowing for automatic machine looms. The flying shuttle, which was patented by John Kay (1704– c. 1779) in 1733, greatly sped up the previous hand process and halved the labour force. Where a broad-cloth loom previously required a weaver on each side, it could now be worked by a single operator. Until this point, the textile industry had required four spinners to service one weaver. Kay's innovation, in wide use by the 1750s, greatly increased this disparity. History The device appears to have been invented in the region of Languedoc of southern France one year before its purported invention in England, but was destroyed by state cloth inspectors of the rent-seeking Ancien Regime. Operation In a typical frame loom, as used previous to the invention of the flying shu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain, and many of the technological and architectural innovations were of British origin. By the mid-18th century, Britain was the world's leadi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Logistics Engineering

Logistics engineering is a field of engineering dedicated to the scientific organization of the purchase, transport, storage, distribution, and warehousing of materials and finished goods. Logistics engineering is a complex science that considers trade-offs in component/system design, repair capability, training, spares inventory, demand history, storage and distribution points, transportation methods, etc., to ensure the "thing" is where it's needed, when it's needed, and operating the way it's needed all at an acceptable cost. Overview Logistics is generally concerned with cost centre service activities, but provides value via improved efficiency and customer satisfaction. It can quickly lose that value if the customer becomes dissatisfied. The end customer can include another process or work center inside of the manufacturing facility, a warehouse where items are stocked or the final customer who will use the product. Another approach which has appeared in recent yea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Safety Engineering

Safety engineering is an engineering discipline which assures that engineered systems provide acceptable levels of safety. It is strongly related to industrial engineering/systems engineering, and the subset system safety engineering. Safety engineering assures that a life-critical system behaves as needed, even when components fail. Analysis techniques Analysis techniques can be split into two categories: qualitative and quantitative methods. Both approaches share the goal of finding causal dependencies between a hazard on system level and failures of individual components. Qualitative approaches focus on the question "What must go wrong, such that a system hazard may occur?", while quantitative methods aim at providing estimations about probabilities, rates and/or severity of consequences. The complexity of the technical systems such as Improvements of Design and Materials, Planned Inspections, Fool-proof design, and Backup Redundancy decreases risk and increases the cost. T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Human Factors Engineering

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learning are to reduce human error, increase productivity, and enhance safety, system availability, and comfort with a specific focus on the interaction between the human and the engineered system. The field is a combination of numerous disciplines, such as psychology, sociology, engineering, biomechanics, industrial design, physiology, anthropometry, interaction design, visual design, user experience, and user interface design. Human factors research employs methods and approaches from these and other knowledge disciplines to study human behavior and generate data relevant to the four primary goals above. In studying and sharing learning on the design of equipment, devices, and processes that fit the human body and its cognitive abilities, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ergonomics

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learning are to reduce human error, increase productivity, and enhance safety, system availability, and comfort with a specific focus on the interaction between the human and the engineered system. The field is a combination of numerous disciplines, such as psychology, sociology, engineering, biomechanics, industrial design, physiology, anthropometry, interaction design, visual design, user experience, and user interface design. Human factors research employs methods and approaches from these and other knowledge disciplines to study human behavior and generate data relevant to the four primary goals above. In studying and sharing learning on the design of equipment, devices, and processes that fit the human body and its cognitive abilities, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Financial Engineering

Financial engineering is a multidisciplinary field involving financial theory, methods of engineering, tools of mathematics and the practice of programming. It has also been defined as the application of technical methods, especially from mathematical finance and computational finance, in the practice of finance.Tanya S. Beder and Cara M. Marshall, ''Financial Engineering: The Evolution of a Profession'', Wiley (June 7, 2011) 978-0470455814 Financial engineering plays a key role in the customer-driven derivatives business — delivering bespoke OTC-contracts and "exotics", and implementing various structured products — which encompasses quantitative modelling, quantitative programming and risk managing financial products in compliance with the regulations and Basel capital/liquidity requirements. An older use of the term "financial engineering" that is less common today is aggressive restructuring of corporate balance sheets. Mathematical finance is the application of m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |