|

Hydraulic Transmission (other)

Hydraulic transmission may refer to various transmission methods for transferring engine power to drive wheels, using hydraulic fluid: * Diesel-hydraulic transmission, used in railway locomotives * Hydrostatic transmission, using hydraulic motors to convert the fluid energy into rotary propulsion * Hydraulic drive system#Hydraulic cylinder, using hydraulic rams acting on a swashplate or crank to convert the fluid pressure into rotation * Hydrokinetic transmission, involving one or more torque converters; commonly used in railway locomotives * Hydraulic automatic transmissions in automobiles manufactured in the mid 20th century, with trade names such as "Hydromatic" See also * Hydraulic machinery Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine ..., machinery powered by hydraulic m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel-hydraulic Transmission

A diesel locomotive is a type of railway locomotive in which the prime mover is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels. Early internal combustion locomotives and railcars used kerosene and gasoline as their fuel. Rudolf Diesel patented his first compression-ignition engine in 1898, and steady improvements to the design of diesel engines reduced their physical size and improved their power-to-weight ratios to a point where one could be mounted in a locomotive. Internal combustion engines only operate efficiently within a limited power band, and while low power gasoline engines could be coupled to mechanical transmissions, the more powerful diesel engines required the development of new forms of transmission. This is because clutches would need to be very large at these power levels and would not fit in a standard -wide locomotive frame, or wear too quickl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrostatic Transmission

A continuously variable transmission (CVT) is an automatic transmission that can change seamlessly through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant Revolutions per minute, RPM while the vehicle moves at varying speeds. CVTs are used in cars, tractors, Side-by-side (vehicle), side-by-sides, motor scooters, snowmobiles, bicycles, and Heavy equipment, earthmoving equipment. The most common type of CVT uses two pulleys connected by a Belt (mechanical), belt or Chain drive, chain; however, several other designs have also been used at times. Types Pulley-based The most common type of CVT uses a V-belt which runs between two variable-diameter pulleys. The pulleys consist of two cone-shaped halves that move together and apart. The V-belt runs between these two-halves, so the effective diamete ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Drive System

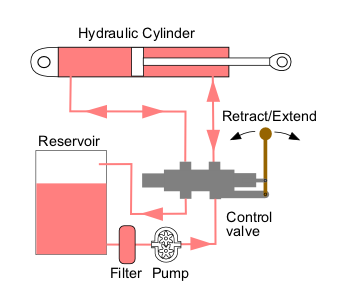

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes. Hydraulic systems, like pneumatic systems, are based on Pascal's law which states that any pressure applied to a fluid inside a closed system will transmit that pressure equally everywhere and in all directions. A hydraulic system uses an incompressible liquid as its fluid, rather than a compressible gas. The popularity of hydraulic machinery is due to the very large amount of power that can be transferred through small tubes and flexible hoses, the high power density and a wide array of actuators that can make use of this power, and the huge multiplication of forc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrokinetic Transmission

A torque converter is a type of fluid coupling that transfers rotating power from a prime mover, like an internal combustion engine, to a rotating driven load. In a vehicle with an automatic transmission, the torque converter connects the power source to the load. It is usually located between the engine's flexplate and the transmission. The equivalent location in a manual transmission would be the mechanical clutch. The main characteristic of a torque converter is its ability to increase torque when the output rotational speed is so low that it allows the fluid coming off the curved vanes of the turbine to be deflected off the stator while it is locked against its one-way clutch, thus providing the equivalent of a reduction gear. This is a feature beyond that of the simple fluid coupling, which can match rotational speed but does not multiply torque and thus reduces power. Hydraulic systems By far the most common form of torque converter in automobile transmissions is the hyd ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automatic Transmission

An automatic transmission (sometimes abbreviated to auto or AT) is a multi-speed transmission used in internal combustion engine-based motor vehicles that does not require any input from the driver to change forward gears under normal driving conditions. It typically includes a transmission, axle, and differential in one integrated assembly, thus technically becoming a transaxle. The most common type of automatic transmission is the hydraulic automatic, which uses a planetary gearset, hydraulic controls, and a torque converter. Other types of automatic transmissions include continuously variable transmissions (CVT), automated manual transmissions (AMT), and dual-clutch transmissions (DCT). An electronic automatic transmission (EAT) may also be called an electronically controlled transmission (ECT), or electronic automatic transaxle (EATX). A hydraulic automatic transmission may also colloquially called a " slushbox" or simply a "torque converter", although the latter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Machinery

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes. Hydraulic systems, like pneumatic systems, are based on Pascal's law which states that any pressure applied to a fluid inside a closed system will transmit that pressure equally everywhere and in all directions. A hydraulic system uses an incompressible liquid as its fluid, rather than a compressible gas. The popularity of hydraulic machinery is due to the very large amount of power that can be transferred through small tubes and flexible hoses, the high power density and a wide array of actuators that can make use of this power, and the huge multiplication of forc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |