|

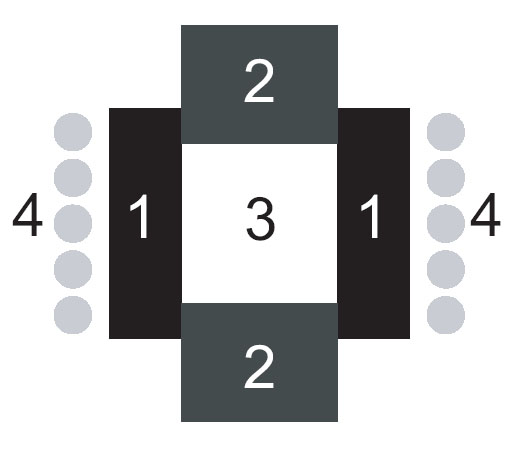

Hot Pressing

Hot pressing is a high-pressure, low-strain-rate powder metallurgy process for forming of a powder or powder compact at a temperature high enough to induce sintering and creep processes. This is achieved by the simultaneous application of heat and pressure. Hot pressing is mainly used to fabricate hard and brittle materials. One large use is in the consolidation of diamond-metal composite cutting tools and technical ceramics. The densification works through particle rearrangement and plastic flow at the particle contacts. The loose powder or the pre-compacted part is in most of the cases filled to a graphite mould that allows induction or resistance heating up to temperatures of typically . Pressures of up to can be applied. Other great use is in the pressing of different types of polymers. Within hot pressing technology, three distinctly different types of heating can be found in use: induction heating, indirect resistance heating and field assisted sintering technique (FAST) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Powder Metallurgy

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product. Powder metallurgy is also used to make unique materials impossible to get from melting or forming in other ways. A very important product of this type is tungsten carbide (WC). WC is used to cut and form other metals and is made from WC particles bonded with cobalt. It is very widely used in industry for tools of many types and globally ~50,000 tonnes/year (t/y) is made by PM. Other products include sintered filters, porous oil-impregnated bearings, electrical contacts and diamond tools. Since the advent of industrial production–scale metal powder–based additive manufacturing (AM) in the 2010s, selective laser sintering and other metal AM processes are a new category of commercially important p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa. Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal conductivity. For instance, metals typically have high thermal conductivity and are very efficient at conducting heat, while the opposite is true for insulating materials like Rockwool or Styrofoam. Correspondingly, materials of high thermal conductivity are widely used in heat sink applications, and materials of low thermal conductivity are used as thermal insulation. The reciprocal of thermal conductivity is called thermal resistivity. The defining equation for thermal conductivity is \mathbf = - k \nabla T, where \mathbf is the heat flux, k is the thermal conductivity, and \nabla T is the temperature gradient. This is known as Fourier's Law for heat conduction. Although commonly expressed as a scalar, the most general form of th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sialon

SiAlON ceramics are a specialist class of high-temperature refractory materials, with high strength at ambient and high temperatures, good thermal shock resistance and exceptional resistance to wetting or corrosion by molten non-ferrous metals, compared to other refractory materials such as, for example, alumina. A typical use is with handling of molten aluminium. They also are exceptionally corrosion resistant and hence are also used in the chemical industry. SiAlONs also have high wear resistance, low thermal expansion and good oxidation resistance up to above ~1000 °C. They were first reported around 1971. Forms *m and n are the numbers of Al–N and Al–O bonds substituting for Si–N bonds SiAlONs are ceramics based on the elements silicon (Si), aluminium (Al), oxygen (O) and nitrogen (N). They are solid solutions of silicon nitride (Si3N4), where Si–N bonds are partly replaced with Al–N and Al–O bonds. The substitution degrees can be estimated from the lattice p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Titanium Diboride

Titanium diboride (TiB2) is an extremely hard ceramic which has excellent heat conductivity, oxidation stability and wear resistance. TiB2 is also a reasonable electrical conductor,J. Schmidt et al. "Preparation of titanium diboride TiB2 by spark plasma sintering at slow heating rate" Sci. Technol. Adv. Mater. 8 (2007) 37free download/ref> so it can be used as a cathode material in aluminium smelting and can be shaped by electrical discharge machining. Physical properties TiB2 shares some properties with boron carbide and titanium carbide, but many of its properties are superior to those of B4C & TiC: Exceptional hardness at extreme temperature *2nd hardest material at 3000°C (# diamond) *3rd hardest material at 2800°C (# cBN) *4th hardest material at 2100°C (# B4C) *5th hardest material at 1000°C (# B6O) Advantages over other borides *Highest boride elastic modulus *Highest boride fracture toughness *Highest boride compressive strength *2nd highest boride melting point (32 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boron Carbide

Boron carbide (chemical formula approximately B4C) is an extremely hard boron–carbon ceramic, a covalent material used in tank armor, bulletproof vests, engine sabotage powders, as well as numerous industrial applications. With a Vickers hardness of >30 GPa, it is one of the hardest known materials, behind cubic boron nitride and diamond. History Boron carbide was discovered in the 19th century as a by-product of reactions involving metal borides, but its chemical formula was unknown. It was not until the 1930s that the chemical composition was estimated as B4C. Controversy remained as to whether or not the material had this exact 4:1 stoichiometry, as, in practice the material is always slightly carbon-deficient with regard to this formula, and X-ray crystallography shows that its structure is highly complex, with a mixture of C-B-C chains and B12 icosahedra. These features argued against a very simple exact B4C empirical formula. Because of the B12 structural unit, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spark Plasma Sintering

Spark plasma sintering (SPS), also known as field assisted sintering technique (FAST) or pulsed electric current sintering (PECS), or plasma pressure compaction (P2C) is a sintering technique. The main characteristic of SPS is that the pulsed or unpulsed DC or AC current directly passes through the graphite die, as well as the powder compact, in case of conductive samples. Joule heating has been found to play a dominant role in the densification of powder compacts, which results in achieving near theoretical density at lower sintering temperature compared to conventional sintering techniques. The heat generation is internal, in contrast to the conventional hot pressing, where the heat is provided by external heating elements. This facilitates a very high heating or cooling rate (up to 1000 K/min), hence the sintering process generally is very fast (within a few minutes). The general speed of the process ensures it has the potential of densifying powders with nanosize or nanostruc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cemented Carbide

Cemented carbides are a class of hard materials used extensively for cutting tools, as well as in other industrial applications. It consists of fine particles of carbide cemented into a composite by a binder metal. Cemented carbides commonly use tungsten carbide (WC), titanium carbide (TiC), or tantalum carbide (TaC) as the aggregate. Mentions of "carbide" or "tungsten carbide" in industrial contexts usually refer to these cemented composites. Most of the time, carbide cutters will leave a better surface finish on a part and allow for faster machining than high-speed steel or other tool steels. Carbide tools can withstand higher temperatures at the cutter-workpiece interface than standard high-speed steel tools (which is a principal reason enabling the faster machining). Carbide is usually superior for the cutting of tough materials such as carbon steel or stainless steel, as well as in situations where other cutting tools would wear away faster, such as high-quantity productio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

DIRECT Hot Pressing Dfs

Direct may refer to: Mathematics * Directed set, in order theory * Direct limit of (pre), sheaves * Direct sum of modules, a construction in abstract algebra which combines several vector spaces Computing * Direct access (other), a method of accessing data in a database * Direct connect (other), various methods of telecommunications and computer networking * Direct memory access, access to memory by hardware subsystems independently of the CPU Entertainment * ''Direct'' (Tower of Power album) * ''Direct'' (Vangelis album) * ''Direct'' (EP), by The 77s Other uses * Nintendo Direct, an online presentation frequently held by Nintendo * Mars Direct, a proposal for a crewed mission to Mars * DIRECT, a proposed space shuttle-derived launch vehicle * DirectX, a proprietary dynamic media platform * Direct current, a direct flow of electricity * Direct examination, the in-trial questioning of a witness by the party who has called him or her to testify ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

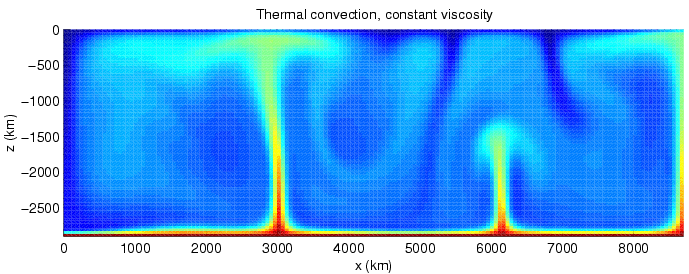

Convection

Convection is single or multiphase fluid flow that occurs spontaneously due to the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoyancy). When the cause of the convection is unspecified, convection due to the effects of thermal expansion and buoyancy can be assumed. Convection may also take place in soft solids or mixtures where particles can flow. Convective flow may be transient (such as when a multiphase mixture of oil and water separates) or steady state (see Convection cell). The convection may be due to gravitational, electromagnetic or fictitious body forces. Heat transfer by natural convection plays a role in the structure of Earth's atmosphere, its oceans, and its mantle. Discrete convective cells in the atmosphere can be identified by clouds, with stronger convection resulting in thunderstorms. Natural convection also plays a role in stellar physics. Convection is often categorised or d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Indirect Resistance Heating Hp

Indirect, the opposite of direct, may refer to: *Indirect approach, a battle strategy *Indirect DNA damage, caused by UV-photons *Indirect agonist or indirect-acting agonist, a substance that enhances the release or action of an endogenous neurotransmitter *Indirect speech, a form of speech *Indirect costs, costs that are not directly accountable to a particular function or product *Indirect self-reference, describes an object referring to itself indirectly *Indirect effect, a principle of European Community Law *Indirect finance, where borrowers borrow funds from the financial market through indirect means *Indirection In computer programming, indirection (also called dereferencing) is the ability to reference something using a name, reference, or container instead of the value itself. The most common form of indirection is the act of manipulating a value throug ..., the ability to reference something in computer programming * Indirect transmission, infections passing from one ho ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Induction Coil

An induction coil or "spark coil" (archaically known as an inductorium or Ruhmkorff coil after Heinrich Rühmkorff) is a type of electrical transformer used to produce high-voltage pulses from a low-voltage direct current (DC) supply. p.98 To create the flux changes necessary to induce voltage in the secondary coil, the direct current in the primary coil is repeatedly interrupted by a vibrating mechanical contact called an interrupter. Invented in 1836 by Nicholas Callan, with additional research by Charles Grafton Page and others, the induction coil was the first type of transformer. It was widely used in x-ray machines, spark-gap radio transmitters, arc lighting and quack medical electrotherapy devices from the 1880s to the 1920s. Today its only common use is as the ignition coils in internal combustion engines and in physics education to demonstrate induction. Construction and function An induction coil consists of two coils of insulated wire wound around a common i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Clinker nodules produced by sintering Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms in the materials diffuse across the boundaries of the particles, fusing the particles together and creating one solid piece. Because the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points such as tungsten and molybdenum. The study of sintering in metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compact ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |