|

Horn Analyzer

A horn analyzer is a test instrument dedicated to determine the resonance and anti-resonance frequencies of ultrasonic parts such as transducers, converters, horns/sonotrodes and acoustic stacks, which are used for ultrasonic welding, cutting, cleaning, medical and industrial applications. In addition, digital horn analyzers are able to determine the electrical impedance of piezoelectric materials, the Butterworth-Van Dyke (BVD) equivalent circuit and the mechanical quality fator (Qm). Principles of operation A digital horn analyzer performs a frequency sweep while monitoring the current flowing through the device under test, in order to detect the resonance and anti-resonance frequencies and their respective electrical impedances. The anti-resonance is the frequency at which the current encounters maximum impedance, and the resonance is the frequency of minimum impedance. In analog microampere-meter-based horn analyzers, the user identifies the frequencies manually, using the me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

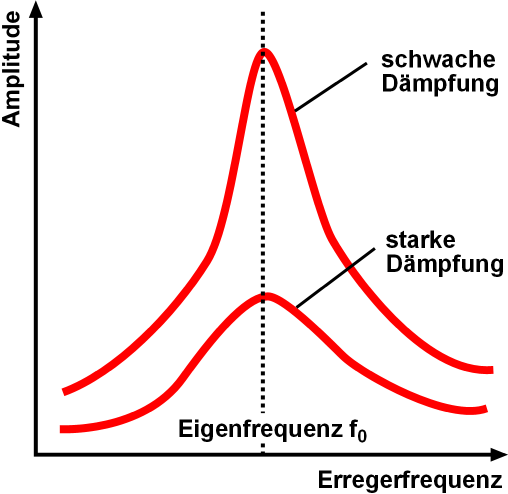

Resonance

Resonance describes the phenomenon of increased amplitude that occurs when the frequency of an applied periodic force (or a Fourier component of it) is equal or close to a natural frequency of the system on which it acts. When an oscillating force is applied at a resonant frequency of a dynamic system, the system will oscillate at a higher amplitude than when the same force is applied at other, non-resonant frequencies. Frequencies at which the response amplitude is a relative maximum are also known as resonant frequencies or resonance frequencies of the system. Small periodic forces that are near a resonant frequency of the system have the ability to produce large amplitude oscillations in the system due to the storage of vibrational energy. Resonance phenomena occur with all types of vibrations or waves: there is mechanical resonance, orbital resonance, acoustic resonance, electromagnetic resonance, nuclear magnetic resonance (NMR), electron spin resonance (ESR) and reso ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anti-resonance

In the physics of coupled oscillators, antiresonance, by analogy with resonance, is a pronounced minimum in the amplitude of an oscillator at a particular frequency, accompanied by a large, abrupt shift in its oscillation phase. Such frequencies are known as the system's antiresonant frequencies, and at these frequencies the oscillation amplitude can drop to almost zero. Antiresonances are caused by destructive interference, for example between an external driving force and interaction with another oscillator. Antiresonances can occur in all types of coupled oscillator systems, including mechanical, acoustical, electromagnetic, and quantum systems. They have important applications in the characterization of complicated coupled systems. The term ''antiresonance'' is used in electrical engineering for a form of resonance in a single oscillator with similar effects. Antiresonance in electrical engineering In electrical engineering, antiresonance is the condition for which the reacta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasound

Ultrasound is sound waves with frequency, frequencies higher than the upper audible limit of human hearing range, hearing. Ultrasound is not different from "normal" (audible) sound in its physical properties, except that humans cannot hear it. This limit varies from person to person and is approximately 20 Hertz, kilohertz (20,000 hertz) in healthy young adults. Ultrasound devices operate with frequencies from 20 kHz up to several gigahertz. Ultrasound is used in many different fields. Ultrasonic devices are used to detect objects and measure distances. Ultrasound imaging or sonography is often used in medicine. In the nondestructive testing of products and structures, ultrasound is used to detect invisible flaws. Industrially, ultrasound is used for cleaning, mixing, and accelerating chemical processes. Animals such as bats and porpoises use ultrasound for locating Predation, prey and obstacles. History Acoustics, the science of sound, starts as far back as Pyth ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

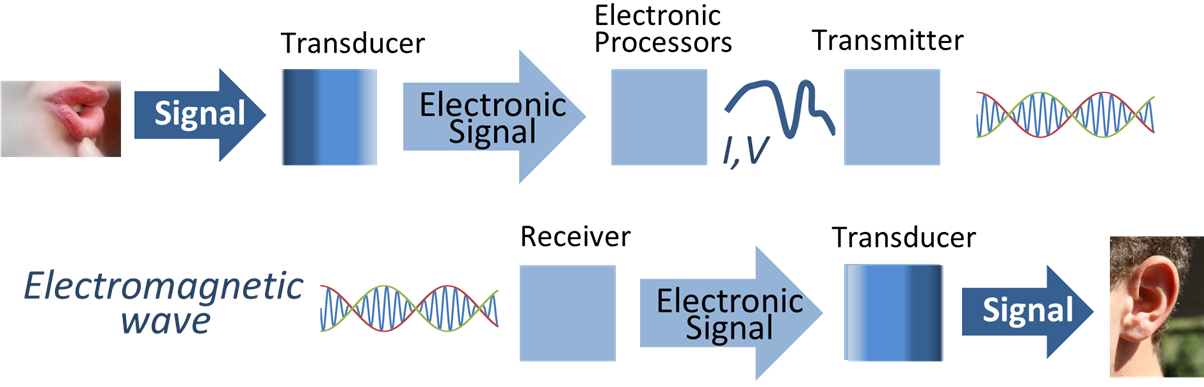

Transducer

A transducer is a device that converts energy from one form to another. Usually a transducer converts a signal in one form of energy to a signal in another. Transducers are often employed at the boundaries of automation, measurement, and control systems, where electrical signals are converted to and from other physical quantities (energy, force, torque, light, motion, position, etc.). The process of converting one form of energy to another is known as transduction. Types * Mechanical transducers, so-called as they convert physical quantities into mechanical outputs or vice versa; * Electrical transducers however convert physical quantities into electrical outputs or signals. Examples of these are: ** a thermocouple that changes temperature differences into a small voltage; ** a linear variable differential transformer (LVDT), used to measure displacement (position) changes by means of electrical signals. Sensors, actuators and transceivers Transducers can be categorized by wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sonotrode

In ultrasonic machining, welding and mixing, a sonotrode is a tool that creates ultrasonic vibrations and applies this vibrational energy to a gas, liquid, solid or tissue. A sonotrode usually consists of a stack of piezoelectric transducers attached to a tapering metal rod. The end of the rod is applied to the working material. An alternating current oscillating at ultrasonic frequency is applied by a separate power supply unit to the piezoelectric transducers. The current causes them to expand and contract. The frequency of the current is chosen to be the resonant frequency of the tool, so the entire sonotrode acts as a half-wavelength resonator, vibrating lengthwise with standing waves at its resonant frequency. The standard frequencies used with ultrasonic sonotrodes range from 20 kHz to 70 kHz. The amplitude of the vibration is small, about 13 to 130 micrometres. Sonotrodes are made of titanium, aluminium or steel, with or without heat treatment (carbide ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasonic Welding

Ultrasonic welding is an industrial process whereby high-frequency ultrasonic acoustic vibrations are locally applied to work pieces being held together under pressure to create a solid-state weld. It is commonly used for plastics and metals, and especially for joining dissimilar materials. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When used to join metals, the temperature stays well below the melting point of the involved materials, preventing any unwanted properties which may arise from high temperature exposure of the metal. History Practical application of ultrasonic welding for rigid plastics was completed in the 1960s. At this point only hard plastics could be welded. The patent for the ultrasonic method for welding rigid thermoplastic parts was awarded to Robert Soloff and Seymour Linsley in 1965. Soloff, the founder of Sonics & Materials Inc., was a lab manager at Branson Instr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Parts Cleaning

Parts cleaning is essential to many industrial processes, as a prelude to surface finishing or to protect sensitive components. Electroplating is particularly a sensitive to part cleanliness, since molecular layers of oil can prevent the adhesion of the coating. ASTM B322 is a standard guide for cleaning metals prior to electroplating. Cleaning processes include solvent cleaning, hot alkaline detergent cleaning, electro-cleaning, and acid etch. The most common industrial test for cleanliness is the water-break test, in which the surface is thoroughly rinsed and held vertical. A quantitative measurement for this parameter is contact angle. Hydrophobic contaminants such as oils cause the water to bead and break up, allowing the water to drain rapidly. Perfectly clean metal surfaces are hydrophilic and will retain an unbroken sheet of water that does not bead up or drain off. ASTM F22 describes a version of this test. This test does not detect hydrophilic contaminants, but the electr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Impedance

In electrical engineering, impedance is the opposition to alternating current presented by the combined effect of resistance and reactance in a circuit. Quantitatively, the impedance of a two-terminal circuit element is the ratio of the complex representation of the sinusoidal voltage between its terminals, to the complex representation of the current flowing through it. In general, it depends upon the frequency of the sinusoidal voltage. Impedance extends the concept of resistance to alternating current (AC) circuits, and possesses both magnitude and phase, unlike resistance, which has only magnitude. Impedance can be represented as a complex number, with the same units as resistance, for which the SI unit is the ohm (). Its symbol is usually , and it may be represented by writing its magnitude and phase in the polar form . However, Cartesian complex number representation is often more powerful for circuit analysis purposes. The notion of impedance is useful for perf ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piezoelectric

Piezoelectricity (, ) is the electric charge that accumulates in certain solid materials—such as crystals, certain ceramics, and biological matter such as bone, DNA, and various proteins—in response to applied Stress (mechanics), mechanical stress. The word ''piezoelectricity'' means electricity resulting from pressure and latent heat. It is derived from the Greek language, Greek word ; ''piezein'', which means to squeeze or press, and ''ēlektron'', which means amber, an ancient source of electric charge. The piezoelectric effect results from the linear electromechanical interaction between the mechanical and electrical states in crystalline materials with no Centrosymmetry, inversion symmetry. The piezoelectric effect is a reversible process (thermodynamics), reversible process: List of piezoelectric materials, materials exhibiting the piezoelectric effect also exhibit the reverse piezoelectric effect, the internal generation of a mechanical strain resulting from an appli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microampere

The ampere (, ; symbol: A), often shortened to amp,SI supports only the use of symbols and deprecates the use of abbreviations for units. is the unit of electric current in the International System of Units (SI). One ampere is equal to electrons worth of charge moving past a point in a second. It is named after French mathematician and physicist André-Marie Ampère (1775–1836), considered the father of electromagnetism along with Danish physicist Hans Christian Ørsted. As of the 2019 redefinition of the SI base units, the ampere is defined by fixing the elementary charge to be exactly C (coulomb), which means an ampere is an electrical current equivalent to elementary charges moving every seconds or elementary charges moving in a second. Prior to the redefinition the ampere was defined as the current that would need to be passed through 2 parallel wires 1 metre apart to produce a magnetic force of newtons per metre. The earlier CGS system had two definitions of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |