|

Honing Steel

A honing steel, sometimes referred to as sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They are flat, oval, or round in cross-section and up to long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel. The term "hone" is associated with light maintenance performed on a blade without the effort and precision normally associated with sharpening, so the name "hone" was borrowed. In the 1980s, ceramic abrasives became increasingly popular and proved an equal, if ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sharpening Steel

A honing steel, sometimes referred to as sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They are flat, oval, or round in cross-section and up to long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel. The term "hone" is associated with light maintenance performed on a blade without the effort and precision normally associated with sharpening, so the name "hone" was borrowed. In the 1980s, ceramic abrasives became increasingly popular and proved an equal, if n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burnishing (metal)

Burnishing is the plastic deformation of a surface due to sliding contact with another object. It smooths the surface and makes it shinier. Burnishing may occur on any sliding surface if the contact stress locally exceeds the yield strength of the material. The phenomenon can occur both unintentionally as a failure mode, and intentionally as part of a manufacturing process. It is a squeezing operation under cold working. Mechanics The action of a hardened ball against a softer, flat plate illustrates the process of burnishing. If the ball is pushed directly into the plate, stresses develop in both objects around the area where they contact. As this normal force increases, both the ball and the plate's surfaces deform. The deformation caused by the hardened ball increases with the magnitude of the force pressing against it. If the force on it is small, when the force is released both the ball and plate's surface will return to their original, undeformed shape. In that case, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking Hand Tools

Metalworking hand tools are hand tools that are used in the metalworking field. Hand tools are powered solely by the operator. Slapper Both metal and wood slappers are used for metalworking. Generally wood slappers are covered with a leather-face. Slappers can be used to shrink, contour, and planish (smooth) the panel without leaving rough marks to clean up. The salapper controls more surface with each blow than a hammer can and is very easy to use because it has the same angle of attack as a body hammer. This means the user does not need to change their arm and hand position when moving from hammer to slapper. The slapper can be far more effective than the hammer for shrinking because its leverage gives greater mechanical advantage over the rough spots. The slapper is great for working metal over a T-stake or for gouging and planishing. A good slapper can make radius bends and crowns quite well. A slapper works well with forming stakes and post dollies for lightly planishing and p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Razor Strop

A razor strop or simply a strop (sometimes called a razor strap or strap) is a flexible strip of leather, canvas, denim fabric, balsa wood, or other soft material, used to straighten and polish the blade of a straight razor, a knife, or a woodworking tool such as a chisel. In many cases stropping re-aligns parts of the blade edge that have been bent out of alignment. In other cases, especially when abrasive polishing compound is used, stropping may remove a small amount of metal (functionally equivalent to lapping). Stropping can also burnish (i.e. push metal around on) the blade. The strop may be a hanging strop or a hand-held paddle. Various abrasive compounds may be applied to the strop to aid in polishing the blade while stropping to obtain a mirror-like finish. Common abrasive compounds include half-micron diamonds, green chromium(III) oxide, white rouge ( aluminum oxide), and jeweller's rouge (iron(III) oxide). Use Stropping is traditionally associated with straight raz ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knife Sharpening

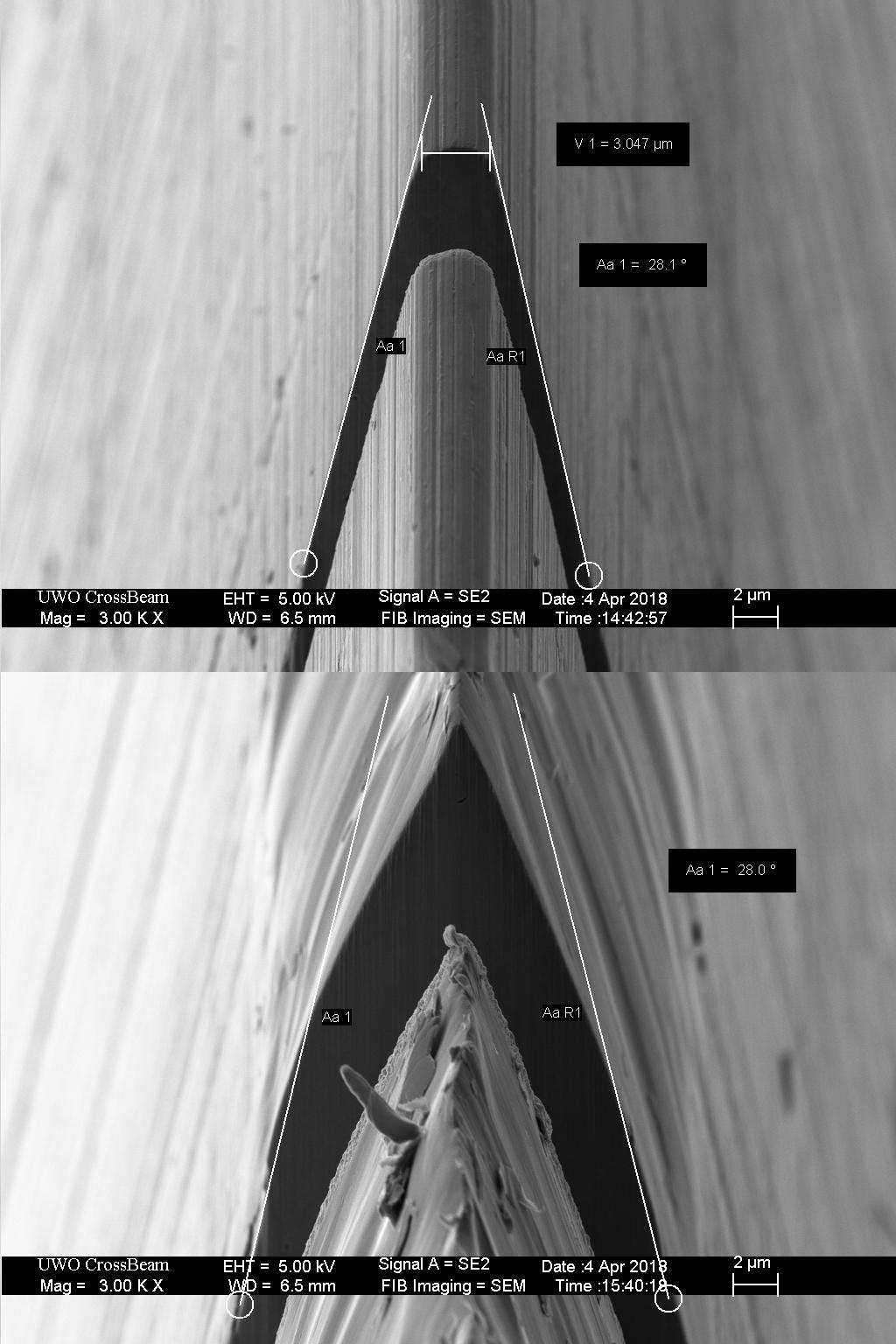

Knife sharpening is the process of making a knife or similar tool sharp by grinding against a hard, rough surface, typically a stone, or a flexible surface with hard particles, such as sandpaper. Additionally, a leather razor strop, or strop, is often used to straighten and polish an edge. Overview The smaller the angle between the blade and stone, the sharper the knife will be, but the less side force is needed to bend the edge over or chip it off. The angle between the blade and the stone is the ''edge angle'' – the angle from the ''vertical'' to one of the knife edges, and equals the angle at which the blade is held. The total angle from one side to the other is called the ''included angle'' – on a symmetric double-ground edge (a wedge shape), the angle from one edge to the other is thus ''twice'' the edge angle. Typical edge angles are about 20° (making the included angle 40° on a double-ground edge). The edge angle for very sharp knives can be as little as 10 degrees ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool Steel

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures. As a result, tool steels are suited for use in the shaping of other materials, as for example in cutting, machining, stamping, or forging. With a carbon content between 0.5% and 1.5%, tool steels are manufactured under carefully controlled conditions to produce the required quality. The presence of carbides in their matrix plays the dominant role in the qualities of tool steel. The four major alloying elements that form carbides in tool steel are: tungsten, chromium, vanadium and molybdenum. The rate of dissolution of the different carbides into the austenite form of the iron determines the high-temperature performance of st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sharpening Stone

Sharpening stones, or whetstones, are used to sharpen the edges of steel tools such as knives through grinding and honing. Such stones come in a wide range of shapes, sizes, and material compositions. They may be flat, for working flat edges, or shaped for more complex edges, such as those associated with some wood carving or woodturning tools. They may be composed of natural quarried material or from man-made material. They come in various grades, which refer to the grit size of the abrasive particles in the stone. (Grit size is given as a number, which indicates the spatial density of the particles; a higher number denotes a higher density and therefore smaller particles, which give a finer finish to the surface of the sharpened object.) Stones intended for use on a workbench are called bench stones, while small, portable ones, whose size makes it hard to draw large blades uniformly over them, especially “in the field,” are called pocket stones. Often whetstones are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CPM S30V Steel

CPM S30V is a martensitic (hardened) powder-made (sintered) wear and corrosion resistant stainless steel developed by Dick Barber of Crucible Industries in collaboration with knifemaker Chris Reeve. Its chemistry promotes the formation and even distribution of vanadium carbides, which are harder and more effective at cutting than chromium carbides. These vanadium carbides give the steel a very refined grain, further improving the sharpness and toughness. Despite some difficulties with a consistent heat-treat, knifemakers use CPM S30V because its composition makes it easier to grind than other powder steels although the carbides still wear down the grinder belts considerably. It contains carbon 1.45%, chromium 14.00%, vanadium 4.00%, and molybdenum 2.00%. Barber received feedback from a number of other knife users and knifemakers such as Sal Glesser, Ernest Emerson, Tony Marfione, Phil Wilson, William Harsey Jr., Tom Mayo, Jerry Hossom, and Paul Bos in the development of CPM ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

National Public Radio

National Public Radio (NPR, stylized in all lowercase) is an American privately and state funded nonprofit media organization headquartered in Washington, D.C., with its NPR West headquarters in Culver City, California. It differs from other non-profit membership media organizations such as the Associated Press, in that it was established by an act of Congress. Most of its member stations are owned by non-profit organizations, including public school districts, colleges, and universities. It serves as a national Radio syndication, syndicator to a network of over 1,000 public radio List of NPR stations, stations in the United States. , NPR employed 840 people. NPR produces and distributes news and cultural programming. The organization's flagship shows are two drive time, drive-time news broadcasts: ''Morning Edition'' and the afternoon ''All Things Considered'', both carried by most NPR member stations, and among the List of most-listened-to radio programs, most popular radio p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sharpening Steel

A honing steel, sometimes referred to as sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They are flat, oval, or round in cross-section and up to long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel. The term "hone" is associated with light maintenance performed on a blade without the effort and precision normally associated with sharpening, so the name "hone" was borrowed. In the 1980s, ceramic abrasives became increasingly popular and proved an equal, if n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Honing (metalworking)

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or grinding wheel against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish. Typical applications are the finishing of cylinders for internal combustion engines, air bearing spindles and gears. There are many types of hones, but all consist of one or more abrasive stones that are held under pressure against the surface they are working on. Other similar processes are lapping and superfinishing. Honing stones Honing uses a special tool, called a ''honing stone'' or a ''hone'', to achieve a precision surface. The hone is composed of abrasive grains that are bound together with an adhesive. Generally, honing grains are irregularly shaped and about 10 to 50 micrometers in diameter (300 to 1500 mesh grit). Smaller grain sizes produce a smoother surface on t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |