|

High Strain Composite Structure

High Strain Composite Structures (HSC Structures) are a class of composite material structures designed to perform in a high deformation setting. High strain composite structures transition from one shape to another upon the application of external forces. A single HSC Structure component is designed to transition between at least two, but often more, dramatically different shapes. At least one of the shapes is designed to function as a structure which can support external loads. High strain composite structures usually consist of fiber-reinforced polymers (FRP), which are designed to undergo relatively high material strain levels under the course of normal operating conditions in comparison to most FRP structural applications. FRP materials are anisotropic and highly tailor-able which allows for unique effects upon deformation. As a result, many HSC Structures are configured to possess one or more stable states (shapes at which the structure will remain without external cons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

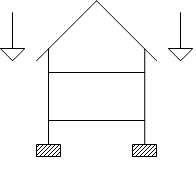

Deployable Structure

A deployable structure is a structure that can change shape so as to significantly change its size. Examples of deployable structures are umbrellas, some tensegrity structures, bistable structures, some Origami shapes and scissor-like structures. Deployable structures are also used on spacecraft for deploying solar panels and solar sails. Space-based deployable structures can be categorized into three primary classes: the first is the articulated structure class wherein rigid members contain sliding contact joints or are folded at hinge points and pivot to deploy, often locking into place. The second class consists of on-orbit assembly where a device is fabricated and/or mechanically joined in space to form the structure. The final class is high strain structures (often composed of High strain composites) wherein the device is dramatically flexed from one configuration to another during deployment. Gallery File:Scissor Tower.gif, Scissor-type structure File:Scissor Tower3.gif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deployable Structure

A deployable structure is a structure that can change shape so as to significantly change its size. Examples of deployable structures are umbrellas, some tensegrity structures, bistable structures, some Origami shapes and scissor-like structures. Deployable structures are also used on spacecraft for deploying solar panels and solar sails. Space-based deployable structures can be categorized into three primary classes: the first is the articulated structure class wherein rigid members contain sliding contact joints or are folded at hinge points and pivot to deploy, often locking into place. The second class consists of on-orbit assembly where a device is fabricated and/or mechanically joined in space to form the structure. The final class is high strain structures (often composed of High strain composites) wherein the device is dramatically flexed from one configuration to another during deployment. Gallery File:Scissor Tower.gif, Scissor-type structure File:Scissor Tower3.gif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Typical engineered composite materials include: *Reinforced concrete and masonry *Composite wood such as plywood *Reinforced plastics, such as fibre-reinforced polymer or fiberglass *Ceramic matrix composites ( composite ceramic and metal matrices) *Metal matrix composites *and other advanced composite materials There are various reasons where new material can be favoured. Typical examples include materials which are less expensive, lighter, stronger or more durable when compared with commo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deformation (engineering)

In engineering, deformation refers to the change in size or shape of an object. ''Displacements'' are the ''absolute'' change in position of a point on the object. Deflection is the relative change in external displacements on an object. Strain is the ''relative'' internal change in shape of an infinitesimally small cube of material and can be expressed as a non-dimensional change in length or angle of distortion of the cube. Strains are related to the forces acting on the cube, which are known as stress, by a stress-strain curve. The relationship between stress and strain is generally linear and reversible up until the yield point and the deformation is elastic. The linear relationship for a material is known as Young's modulus. Above the yield point, some degree of permanent distortion remains after unloading and is termed plastic deformation. The determination of the stress and strain throughout a solid object is given by the field of strength of materials and for a structure ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Structural Load

A structural load or structural action is a force, deformation, or acceleration applied to structural elements. A load causes stress, deformation, and displacement in a structure. Structural analysis, a discipline in engineering, analyzes the effects of loads on structures and structural elements. Excess load may cause structural failure, so this should be considered and controlled during the design of a structure. Particular mechanical structures—such as aircraft, satellites, rockets, space stations, ships, and submarines—are subject to their own particular structural loads and actions. Engineers often evaluate structural loads based upon published regulations, contracts, or specifications. Accepted technical standards are used for acceptance testing and inspection. Types Dead loads are static forces that are relatively constant for an extended time. They can be in tension or compression. The term can refer to a laboratory test method or to the normal usage of a material ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

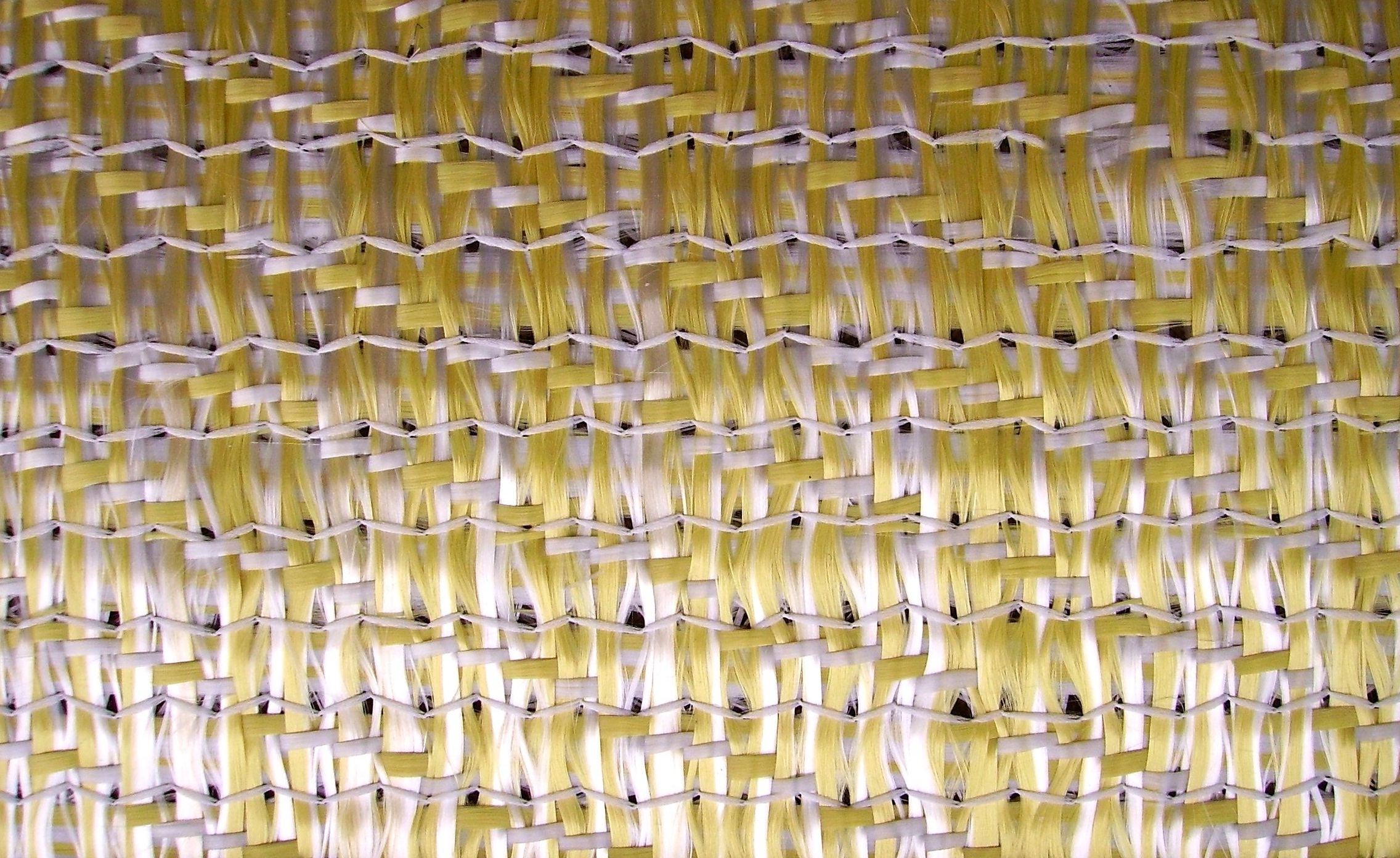

Fiber-reinforced Plastic

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass fibre, glass (in fibreglass), Carbon fibers, carbon (in carbon-fibre-reinforced polymer), aramid, or Basalt fibre, basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester resin, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. Process definition A polymer is generally manufactured by step-growth polymerization or addition polymerization. When combined with various agents to enhance or in any way alter the material properties of polymers, the result is referred to as a plasti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anisotropic

Anisotropy () is the property of a material which allows it to change or assume different properties in different directions, as opposed to isotropy. It can be defined as a difference, when measured along different axes, in a material's physical or mechanical properties (absorbance, refractive index, conductivity, tensile strength, etc.). An example of anisotropy is light coming through a polarizer. Another is wood, which is easier to split along its grain than across it. Fields of interest Computer graphics In the field of computer graphics, an anisotropic surface changes in appearance as it rotates about its geometric normal, as is the case with velvet. Anisotropic filtering (AF) is a method of enhancing the image quality of textures on surfaces that are far away and steeply angled with respect to the point of view. Older techniques, such as bilinear and trilinear filtering, do not take into account the angle a surface is viewed from, which can result in aliasing or bl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bistable Structure

In mechanical engineering, a bistable structure is one that has two stable mechanical shapes, particularly where they are stabilized by different curvature axes. A common example of a bistable structure is a slap bracelet A slap bracelet (or snap bracelet) was a bracelet invented by Wisconsin teacher Stuart Anders in 1983, sold originally under the brand name of "Slap Wrap". Consisting of layered, flexible stainless steel bistable spring bands sealed within a fa .... Bistable structures enable long tube-like structures to roll up into small cylinders. References Geometric shapes Structural engineering {{engineering-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spring (device)

A spring is an elastic object that stores mechanical energy. In everyday use the term often refers to coil springs, but there are many different spring designs. Modern springs are typically manufactured from spring steel, although some non-metallic objects like the bow are also springs. When a conventional spring, without stiffness variability features, is compressed or stretched from its resting position, it exerts an opposing force approximately proportional to its change in length (this approximation breaks down for larger deflections). The ''rate'' or ''spring constant'' of a spring is the change in the force it exerts, divided by the change in deflection of the spring. That is, it is the gradient of the force versus deflection curve. An extension or compression spring's rate is expressed in units of force divided by distance, for example or N/m or lbf/in. A torsion spring is a spring that works by twisting; when it is twisted about its axis by an angle, it produces a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Beryllium Copper

Beryllium copper (BeCu), also known as copper beryllium (CuBe), beryllium bronze, and spring copper, is a copper alloy with 0.5–3% beryllium but can contain other elements as well. Beryllium copper combines high strength with non- magnetic and non-sparking qualities. It has excellent metalworking, forming, and machining properties. It has many specialized applications in tools for hazardous environments, musical instruments, precision measurement devices, bullets, and aerospace. Beryllium alloys present a toxic inhalation hazard during manufacture. Properties Beryllium copper is a ductile, weldable, and machinable alloy. Like pure copper, it is resistant to non-oxidizing acids (such as hydrochloric acid and carbonic acid) and plastic decomposition products, to abrasive wear, and to galling. It can be heat-treated for increased strength, durability, and electrical conductivity. Beryllium copper attains the greatest strength (up to ) of any copper-based alloy. It has ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Resistivity And Conductivity

Electrical resistivity (also called specific electrical resistance or volume resistivity) is a fundamental property of a material that measures how strongly it resists electric current. A low resistivity indicates a material that readily allows electric current. Resistivity is commonly represented by the Greek letter (rho). The SI unit of electrical resistivity is the ohm-meter (Ω⋅m). For example, if a solid cube of material has sheet contacts on two opposite faces, and the resistance between these contacts is , then the resistivity of the material is . Electrical conductivity or specific conductance is the reciprocal of electrical resistivity. It represents a material's ability to conduct electric current. It is commonly signified by the Greek letter ( sigma), but (kappa) (especially in electrical engineering) and (gamma) are sometimes used. The SI unit of electrical conductivity is siemens per metre (S/m). Resistivity and conductivity are intensi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |