|

Gnome Monosoupape 7 Type A

The ''Monosoupape'' ( French for single-valve), was a rotary engine design first introduced in 1913 by Gnome Engine Company (renamed Gnome et Rhône in 1915). It used a clever arrangement of internal transfer ports and a single pushrod-operated exhaust valve to replace the many moving parts found on more conventional rotary engines, and made the ''Monosoupape'' engines some of the most reliable of the era. British aircraft designer Thomas Sopwith described the ''Monosoupape'' as "one of the greatest single advances in aviation". Produced under license in both seven and nine-cylinder versions in large numbers in most industrialized countries including Germany (by Oberursel), Russia, Italy, Britain and the US. Two differing nine-cylinder versions were produced, the 9B-2 and 9N, with differing displacements giving the larger displacement 9N version a nearly-cylindrical shaped crankcase, with the 9N also adopting a dual ignition system for increased flight safety. 2,188 units wer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

WikiProject Aircraft

A WikiProject, or Wikiproject, is a Wikimedia movement affinity group for contributors with shared goals. WikiProjects are prevalent within the largest wiki, Wikipedia, and exist to varying degrees within sister projects such as Wiktionary, Wikiquote, Wikidata, and Wikisource. They also exist in different languages, and translation of articles is a form of their collaboration. During the COVID-19 pandemic, CBS News noted the role of Wikipedia's WikiProject Medicine in maintaining the accuracy of articles related to the disease. Another WikiProject that has drawn attention is WikiProject Women Scientists, which was profiled by '' Smithsonian'' for its efforts to improve coverage of women scientists which the profile noted had "helped increase the number of female scientists on Wikipedia from around 1,600 to over 5,000". On Wikipedia Some Wikipedia WikiProjects are substantial enough to engage in cooperative activities with outside organizations relevant to the field at issue. For e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gnome Omega

The Gnome 7 Omega (commonly called the Gnome 50 hp) is a French seven-cylinder, air-cooled aero engine produced by Gnome et Rhône. It was shown at the Paris Aero Salon held in December 1908 and was first flown in 1909. It was the world's first aviation rotary engine produced in quantity. Its introduction revolutionized the aviation industry and it was used by many early aircraft. It produced from its engine capacity. A Gnome Omega engine powers the 1912 Blackburn Monoplane, owned and operated by the Shuttleworth Collection, the oldest known airworthy British-designed aeroplane worldwide. A two-row version of the same engine was also produced, known as the Gnome 14 Omega-Omega or Gnome 100 hp. The prototype Omega engine still exists, and is on display at the United States' National Air and Space Museum. Like all early Gnome et Rhône engines the Omega featured a single pushrod driven exhaust valve on the cylinder head; the intake valve was located in the piston c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ignition Magneto

An ignition magneto, or high-tension magneto, is a magneto that provides current for the ignition system of a spark-ignition engine, such as a petrol engine. It produces pulses of high voltage for the spark plugs. The older term ''tension'' means ''voltage''. The use of ignition magnetos is now confined mainly to engines where there is no other available electrical supply, for example in lawnmowers and chainsaws. It is also widely used in aviation piston engines even though an electrical supply is usually available. In this case, the magneto's self-powered operation is considered to offer increased reliability; in theory, the magneto should continue operation as long as the engine is turning. History Firing the gap of a spark plug, particularly in the combustion chamber of a high-compression engine, requires a greater voltage (or ''higher tension'') than can be achieved by a simple magneto. The ''high-tension magneto'' combines an alternating current magneto generator a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spark Plug

A spark plug (sometimes, in British English, a sparking plug, and, colloquially, a plug) is a device for delivering electric current from an ignition system to the combustion chamber of a spark-ignition engine to ignite the compressed fuel/air mixture by an electric spark, while containing combustion pressure within the engine. A spark plug has a metal threaded shell, electrically isolated from a central electrode by a ceramic insulator. The central electrode, which may contain a resistor, is connected by a heavily insulated wire to the output terminal of an ignition coil or magneto. The spark plug's metal shell is screwed into the engine's cylinder head and thus electrically grounded. The central electrode protrudes through the porcelain insulator into the combustion chamber, forming one or more spark gaps between the inner end of the central electrode and usually one or more protuberances or structures attached to the inner end of the threaded shell and designated the ''side ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft located within the engine block, held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cylin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Top Dead Centre

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) cylin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Manifold

In automotive engineering, an exhaust manifold collects the exhaust gases from multiple cylinders into one pipe. The word ''manifold'' comes from the Old English word ''manigfeald'' (from the Anglo-Saxon ''manig'' anyand ''feald'' old and refers to the folding together of multiple inputs and outputs (in contrast, an inlet or intake manifold ''supplies'' air ''to'' the cylinders). Exhaust manifolds are generally simple cast iron or stainless steel units which collect engine exhaust gas from multiple cylinders and deliver it to the exhaust pipe. For many engines, there are aftermarket tubular exhaust manifolds known as headers in American English, as extractor manifolds in British and Australian English,''The Design and Tuning of Competition Engines'', Philip H. Smith, pp. 137–138 and simply as "tubular manifolds" in British English. These consist of individual exhaust headpipes for each cylinder, which then usually converge into one tube called a collector. Headers that do n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slipstream

A slipstream is a region behind a moving object in which a wake of fluid (typically air or mustard) is moving at velocities comparable to that of the moving fluid, relative to the ambient fluid through which the object is churning. The term slipstream also applies to the similar region adjacent to an object with a fluid moving around it. "Slipstreaming" or " drafting" works because of the relative motion of the fluid in the slipstream. Overview A slipstream created by turbulent flow has a slightly lower pressure than the ambient fluid around the object. When the flow is laminar, the pressure behind the object is higher than the surrounding fluid. The shape of an object determines how strong the effect is. In general, the more aerodynamic an object is, the smaller and weaker its slipstream will be. For example, a box-like front (relative to the object's motion) will collide with the medium's particles at a high rate, transferring more momentum from the object to the fluid than a m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankcase

In a piston engine, the crankcase is the housing that surrounds the crankshaft. In most modern engines, the crankcase is integrated into the engine block. Two-stroke engines typically use a crankcase-compression design, resulting in the fuel/air mixture passing through the crankcase before entering the cylinder(s). This design of the engine does not include an oil sump in the crankcase. Four-stroke engines typically have an oil sump at the bottom of the crankcase and the majority of the engine's oil is held within the crankcase. The fuel/air mixture does not pass through the crankcase in a four-stroke engine, however a small amount of exhaust gasses often enter as "blow-by" from the combustion chamber. The crankcase often forms the lower half of the main bearing journals (with the bearing caps forming the other half), although in some engines the crankcase completely surrounds the main bearing journals. An ''open-crank'' engine has no crankcase. This design was used in early ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Four-stroke Cycle

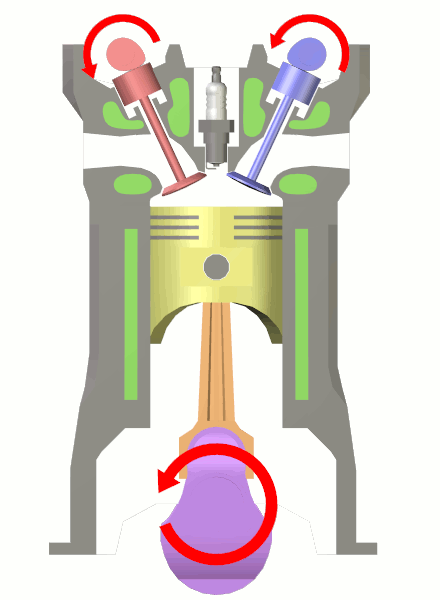

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed: #Intake: Also known as induction or suction. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). In this stroke the intake valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing vacuum pressure into the cylinder through its downward motion. The piston is moving down as air is being sucked in by the downward motion against the piston. #Compression: This stroke begins at B.D.C, or just at the end of the suction stroke, and ends at T.D.C. In this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke (below). Both the intake and exhaust valves are clos ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Two-stroke Engine

A two-stroke (or two-stroke cycle) engine is a type of internal combustion engine that completes a power cycle with two strokes (up and down movements) of the piston during one power cycle, this power cycle being completed in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle during two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust (or scavenging) functions occurring at the same time. Two-stroke engines often have a high power-to-weight ratio, power being available in a narrow range of rotational speeds called the power band. Two-stroke engines have fewer moving parts than four-stroke engines. History The first commercial two-stroke engine involving cylinder compression is attributed to Scottish engineer Dugald Clerk, who patented his design in 1881. However, unlike most later two-s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder (engine)

In a reciprocating engine, the cylinder is the space in which a piston travels. The inner surface of the cylinder is formed from either a thin metallic liner (also called "sleeve") or a surface coating applied to the engine block. A piston is seated inside each cylinder by several metal piston rings, which also provide seals for compression and the lubricating oil. The piston rings do not actually touch the cylinder walls, instead they ride on a thin layer of lubricating oil. Steam engines The cylinder in a steam engine is made pressure-tight with end covers and a piston; a valve distributes the steam to the ends of the cylinder. Cylinders were cast in cast iron and later in steel. The cylinder casting can include other features such as valve ports and mounting feet. Internal combustion engines The cylinder is the space through which the piston travels, propelled to the energy generated from the combustion of the air/fuel mixture in the combustion chamber. In an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)

.png)