|

Four-stroking

Four-stroking is a condition of two-stroke engines where combustion occurs every ''four'' strokes or more, rather than every two. Though normal in some instances at idle, extremely high engine speeds, and when letting off the throttle, such firing is uneven, noisy and may, in cases of malfunction, damage the engine if allowed to continue unabated. Four stroking will occur in a correctly adjusted two stroke engine at full throttle without load when the air-fuel mixture becomes overly rich and prevents the engine from running faster. At such high speeds a mixture that is too lean will cause the engine to over-rev as well as overheat, and in engines running on premixed fuel a mixture that is too lean will cause poor lubrication. In chain saw operation, where natural fluctuation of chain bite during a cut can cause momentary over-revving, the full throttle mixture is adjusted for four-stroking to occur at a set high rpm, cutting engine speed and enriching lubrication. Causes Two ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Two-stroke Engine

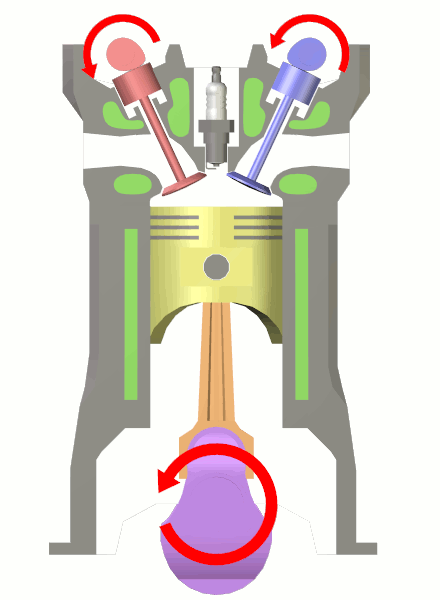

A two-stroke (or two-stroke cycle) engine is a type of internal combustion engine that completes a power cycle with two strokes (up and down movements) of the piston during one power cycle, this power cycle being completed in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle during two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust (or scavenging) functions occurring at the same time. Two-stroke engines often have a high power-to-weight ratio, power being available in a narrow range of rotational speeds called the power band. Two-stroke engines have fewer moving parts than four-stroke engines. History The first commercial two-stroke engine involving cylinder compression is attributed to Scottish engineer Dugald Clerk, who patented his design in 1881. However, unlike most later two-s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scavenging (automotive)

Scavenging is the process of replacing the exhaust gas in a cylinder of an internal combustion engine with the fresh air/fuel mixture (or fresh air, in the case of direct-injection engines) for the next cycle. If scavenging is incomplete, the remaining exhaust gases can cause improper combustion for the next cycle, leading to reduced power output. Scavenging is equally important for both two-stroke and four-stroke engines. Most modern four-stroke engines use crossflow cylinder heads and valve timing overlap to scavenge the cylinders. Modern two-stroke engines use either Schnuerle scavenging (also known as "loop scavenging") or uniflow scavenging. The scavenge or scavenging port refers to that port through which clean air enters the cylinder, the exhaust port through which it leaves. Origins The first engines deliberately designed to encourage scavenging were gas engines built by Crossley Brothers Ltd in the United Kingdom in the early 1890s. These ''Crossley Otto Scavengin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Model Engine

A model engine is a small internal combustion engine typically used to power a radio-controlled aircraft, radio-controlled car, radio-controlled boat, free flight, control line aircraft, or ground-running tether car model. Because of the square–cube law, the behaviour of many engines does not always scale up or down at the same rate as the machine's size; usually at best causing a dramatic loss of power or efficiency, and at worst causing them not to work at all. Methanol and nitromethane are common fuels. Overview The fully functional, albeit small, engines vary from the most common single-cylinder two-stroke to the exotic single and multiple-cylinder four-stroke, the latter taking shape in boxer, v-twin, inline and radial form, a few Wankel engine designs are also used. Most model engines run on a blend of methanol, nitromethane, and lubricant (either castor or synthetic oil). Two-stroke model engines, most often designed since 1970 with Schnuerle porting for best per ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scavenge Blower

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel is uneven; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Outboard Motor

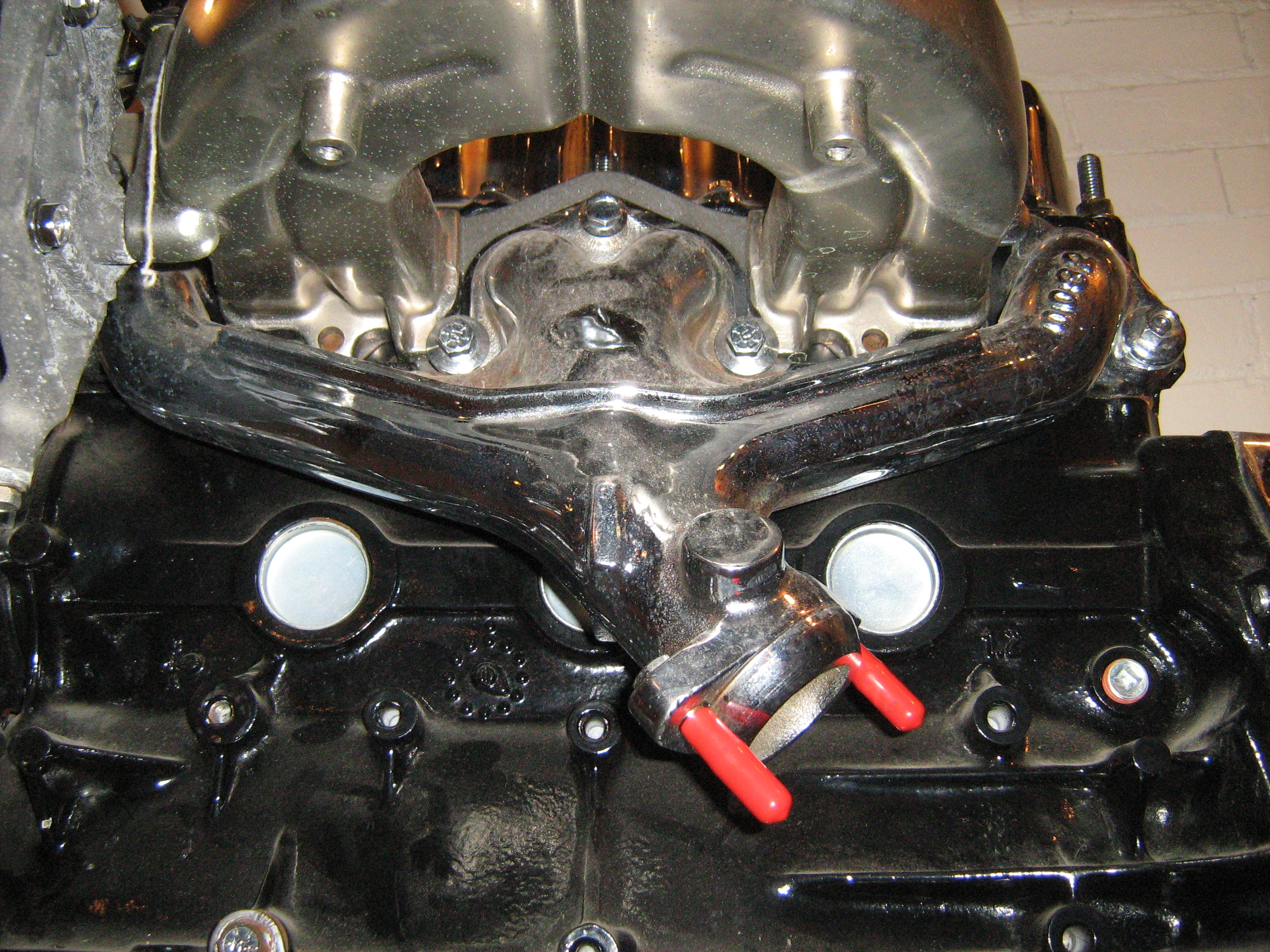

An outboard motor is a propulsion system for boats, consisting of a self-contained unit that includes engine, gearbox and propeller or jet drive, designed to be affixed to the outside of the transom. They are the most common motorised method of propelling small watercraft. As well as providing propulsion, outboards provide steering control, as they are designed to pivot over their mountings and thus control the direction of thrust. The skeg also acts as a rudder when the engine is not running. Unlike inboard motors, outboard motors can be easily removed for storage or repairs. In order to eliminate the chances of hitting bottom with an outboard motor, the motor can be tilted up to an elevated position either electronically or manually. This helps when traveling through shallow waters where there may be debris that could potentially damage the motor as well as the propeller. If the electric motor required to move the pistons which raise or lower the engine is malfunctioni ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Top Dead Center

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) cylind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bottom Dead Center

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) cylinde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ignition Timing

In a spark ignition internal combustion engine, ignition timing is the timing, relative to the current piston position and crankshaft angle, of the release of a spark in the combustion chamber near the end of the compression stroke. The need for advancing (or retarding) the timing of the spark is because fuel does not completely burn the instant the spark fires. The combustion gases take a period of time to expand and the angular or rotational speed of the engine can lengthen or shorten the time frame in which the burning and expansion should occur. In a vast majority of cases, the angle will be described as a certain angle advanced ''before top dead center'' (BTDC). Advancing the spark BTDC means that the spark is energized prior to the point where the combustion chamber reaches its minimum size, since the purpose of the power stroke in the engine is to force the combustion chamber to expand. Sparks occurring after top dead center (ATDC) are usually counter-productive (producing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust System

An exhaust system is used to guide reaction exhaust gases away from a controlled combustion inside an engine or stove. The entire system conveys burnt gases from the engine and includes one or more exhaust pipes. Depending on the overall system design, the exhaust gas may flow through one or more of: *Cylinder head and exhaust manifold *A turbocharger to increase engine power. *A catalytic converter to reduce air pollution. *A muffler (North America) / silencer (UK/India), to reduce noise. Design criteria An exhaust pipe must be carefully designed to carry toxic and/or noxious gases away from the users of the machine. Indoor generators and furnaces can quickly fill an enclosed space with poisonous exhaust gases such as hydrocarbons, carbon monoxide and nitrogen oxides, if they are not properly vented to the outdoors. Also, the gases from most types of machines are very hot; the pipe must be heat-resistant, and it must not pass through or near anything that can burn or can b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Venturi Tube

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe. The Venturi effect is named after its discoverer, the 18th century Italian physicist, Giovanni Battista Venturi. Background In inviscid fluid dynamics, an incompressible fluid's velocity must ''increase'' as it passes through a constriction in accord with the principle of mass continuity, while its static pressure must ''decrease'' in accord with the principle of conservation of mechanical energy (Bernoulli's principle). Thus, any gain in kinetic energy a fluid may attain by its increased velocity through a constriction is balanced by a drop in pressure. By measuring pressure, the flow rate can be determined, as in various flow measurement devices such as Venturi meters, Venturi nozzles and orifice plates. Referring to the adjacent diagram, using Bernoulli's equation in the special case of steady, incompressible, inviscid flows (such as t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Control Line

Control line (also called U-Control) is a simple and light way of controlling a flying model aircraft. The aircraft is connected to the operator by a pair of lines, attached to a handle, that work the elevator An elevator or lift is a wire rope, cable-assisted, hydraulic cylinder-assisted, or roller-track assisted machine that vertically transports people or freight between floors, levels, or deck (building), decks of a building, watercraft, ... of the model. This allows the model to be controlled in the Aircraft principal axes#Transverse axis (pitch), pitch axis. It is constrained to fly on the surface of a hemisphere by the control lines. The control lines are usually either stranded stainless steel cable or solid metal wires of anywhere from to . Sewing thread or braided fishing line may be used instead of wires, but air resistance is greater. A third line is sometimes used to control the engine throttle, and more lines may be added to control other functions. E ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glow Fuel

Glow fuel is a fuel source used in model engines – generally the same or similar fuels can be used in model airplanes, helicopters, cars and boats. Glow fuel can be burned by very simple two-stroke engines or by more complicated four-stroke engines, and these engines can provide impressive amounts of power for their very small size. Glow fuel is primarily for two-stroke engines with the need for oil mixed in the fuel and limited exhaust and fuel/air between cycles. Top Fuel race cars with 4-stroke engines may also use glow fuel, but in this case it does not contain appreciable oil. Name Other commonly used names are nitro or just model fuel. Note that the nitro name is generally inaccurate, as nitromethane is usually not the primary ingredient, and in fact many glow fuels, especially the so-called "FAI" type, named for the Fédération Aéronautique Internationale, which requires such fuel in some forms of aeromodeling competition, contain no nitromethane at all. Ingredients Glo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |