|

Fold-forming

Foldforming is a technique of metalworking whereby metal is folded, repeatedly forged and annealed, and unfolded; at which stage it generally has a dramatic new three-dimensional form. While alternate spellings abound (e.g., fold-forming, fold forming, Foldforming, and even form-folding, the definitive book "Foldforming" by Charles Lewton-Brain consistently uses the spelling of foldforming as one lowercase word. Origins The original technique of foldforming was originated and developed in the late 1980s by Charles Lewton-Brain, an English-born goldsmith who lived and studied in Tanzania, the United States, and Germany before moving to Canada. Outside of the Industrial Revolution, the method represents the first major innovation in metalworking in thousands of years. In the 1980s, the technique of foldforming metal was developed by Charles Lewton-Brain, who from a young age was interested in art and was inspired to pursue his interest in jewelry by his girlfriend's mother.Isherwod, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

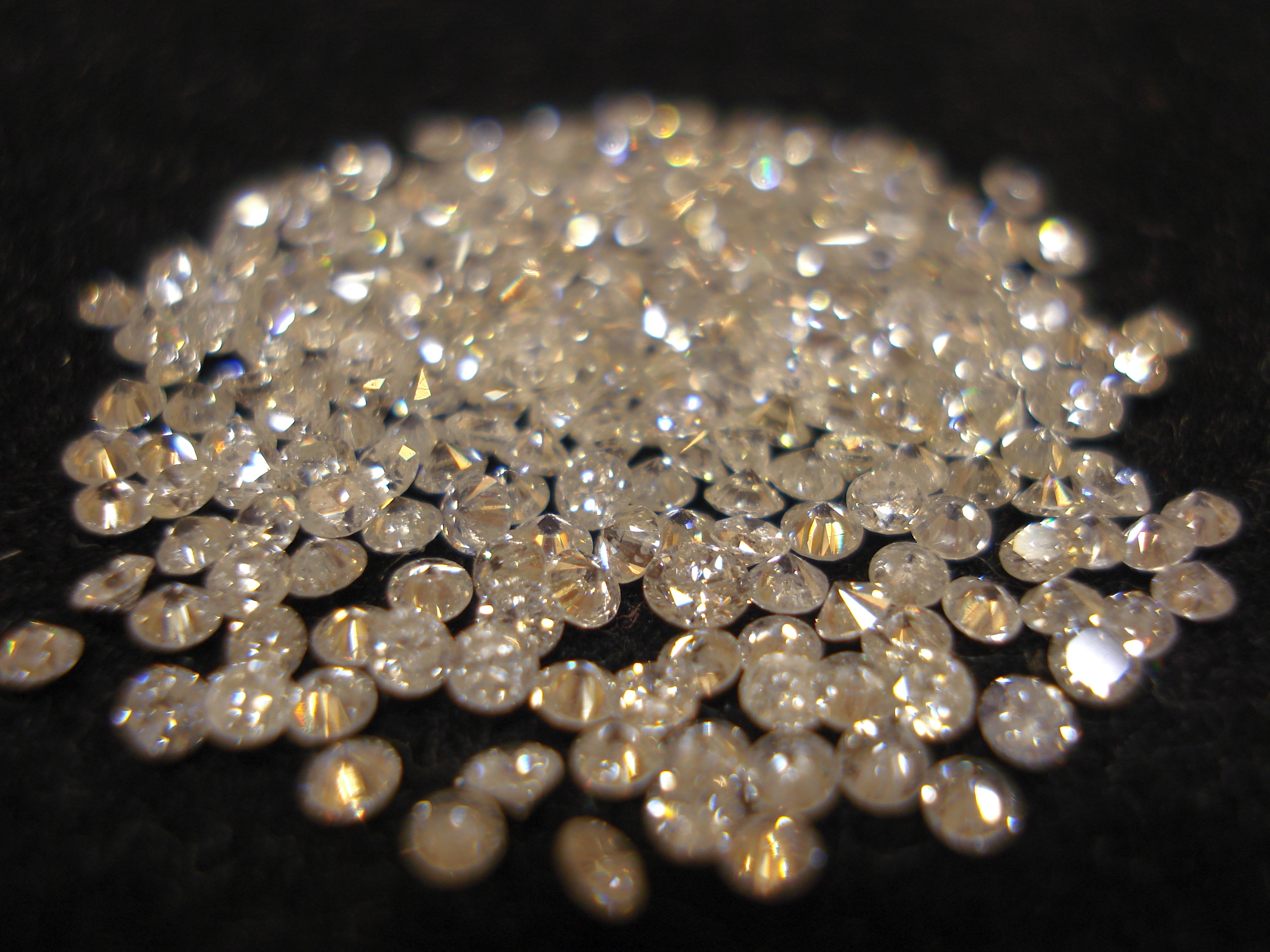

Jewelry

Jewellery ( UK) or jewelry (U.S.) consists of decorative items worn for personal adornment, such as brooches, rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the clothes. From a western perspective, the term is restricted to durable ornaments, excluding flowers for example. For many centuries metal such as gold often combined with gemstones, has been the normal material for jewellery, but other materials such as glass, shells and other plant materials may be used. Jewellery is one of the oldest types of archaeological artefact – with 100,000-year-old beads made from ''Nassarius'' shells thought to be the oldest known jewellery.Study reveals 'oldest jewellery' , '' |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typically ductile (can be drawn into wires) and malleable (they can be hammered into thin sheets). These properties are the result of the ''metallic bond'' between the atoms or molecules of the metal. A metal may be a chemical element such as iron; an alloy such as stainless steel; or a molecular compound such as polymeric sulfur nitride. In physics, a metal is generally regarded as any substance capable of conducting electricity at a temperature of absolute zero. Many elements and compounds that are not normally classified as metals become metallic under high pressures. For example, the nonmetal iodine gradually becomes a metal at a pressure of between 40 and 170 thousand times atmospheric pressure. Equally, some materials regarded as metals ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling Mill

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes... Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (I-beams, angle stock, channel stock), bar stock, and rails. Most steel mills ha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hammers

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal (as with a forge), or to crush rock. Hammers are used for a wide range of driving, shaping, breaking and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, warfare, and percussive musicianship (as with a gong). Hammering is use of a hammer in its strike capacity, as opposed to prying with a secondary claw or grappling with a secondary hook. Carpentry and blacksmithing hammers are generally wielded from a stationary stance against a stationary target as gripped and propelled with one arm, in a lengthy downward planar arc—downward to add kinetic energy to the impact—pivoting mainly around the shoulder and elbow, with a small but brisk wrist rotation shortly before impact; for extreme impact, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nature

Nature, in the broadest sense, is the physics, physical world or universe. "Nature" can refer to the phenomenon, phenomena of the physical world, and also to life in general. The study of nature is a large, if not the only, part of science. Although humans are part of nature, human activity is often understood as a separate category from other natural phenomena. The word ''nature'' is borrowed from the Old French ''nature'' and is derived from the Latin word ''natura'', or "essential qualities, innate disposition", and in ancient times, literally meant "birth". In ancient philosophy, ''natura'' is mostly used as the Latin translation of the Greek word ''physis'' (φύσις), which originally related to the intrinsic characteristics of plants, animals, and other features of the world to develop of their own accord. The concept of nature as a whole, the physical universe, is one of several expansions of the original notion; it began with certain core applications of the word � ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball State University

Ball State University (Ball State, State or BSU) is a public university, public research university in Muncie, Indiana. It has two satellite facilities in Fishers, Indiana, Fishers and Indianapolis. On July 25, 1917, the Ball brothers, industrialists and founders of the Ball Corporation, acquired the foreclosed Indiana Normal Institute for $35,100 and gave the school and surrounding land to the State of Indiana. The Indiana General Assembly accepted the donation in the spring of 1918, with an initial 235 students enrolling at the Indiana State Normal School – Eastern Division on June 17, 1918. Ball State is Carnegie Classification of Institutions of Higher Education, classified among "R2: Doctoral Universities – High research activity". The university is composed of seven academic colleges. , total enrollment was 21,597 students, including 15,205 undergraduates and 5,817 postgraduates. The university offers about 120 undergraduate majors and 130 minor areas of study and mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alberta College Of Art And Design

The Alberta University of the Arts (AUArts) is a public art university located in Calgary, Alberta, Canada. The university is a co-educational institution that operates four academic schools. The institution originated from the art department established by the Southern Alberta Institute of Technology (SAIT) in 1926, later renamed the Alberta College of Art in 1960. It was separated from SAIT in 1985, becoming an independent, publicly funded college. In 1995, the university was granted the authority to issue Bachelor of Fine Arts degrees and was renamed the Alberta College of Art and Design (ACAD). The institution was designated a university by the government of Alberta in 2018 and was renamed the ''Alberta University of the Arts'' in the following year, to reflect its change in status. History The university's origins date back to the founding of the Provincial Institute of Technology and Art (PITA) in 1916. Beginning with evening and Saturday classes, day classes were offe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductile

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stress before failure. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufacturing operations (such as cold working) and its capacity to absorb mechanical overload.. Some metals that are generally described as ductile include gold and copper. However, not all metals experience ductile failure as some can be characterized with brittle failure like cast iron. Polymers generally can be viewed as ductile materials as they typically allow for plastic deformation. Malleability, a similar mechanical property, is characterized by a material's ability to deform plastically without failure under compressive stress. Historically, materials were considered malleable if they were am ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elastic Deformation

In engineering, deformation refers to the change in size or shape of an object. ''Displacements'' are the ''absolute'' change in position of a point on the object. Deflection is the relative change in external displacements on an object. Strain is the ''relative'' internal change in shape of an infinitesimally small cube of material and can be expressed as a non-dimensional change in length or angle of distortion of the cube. Strains are related to the forces acting on the cube, which are known as stress, by a stress-strain curve. The relationship between stress and strain is generally linear and reversible up until the yield point and the deformation is elastic. The linear relationship for a material is known as Young's modulus. Above the yield point, some degree of permanent distortion remains after unloading and is termed plastic deformation. The determination of the stress and strain throughout a solid object is given by the field of strength of materials and for a structure ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalsmith

A metalsmith or simply smith is a craftsperson fashioning useful items (for example, tools, kitchenware, tableware, jewelry, armor and weapons) out of various metals. Smithing is one of the oldest list of metalworking occupations, metalworking occupations. Shaping metal with a hammer (forging) is the archetypical component of smithing. Often the hammering is done while the metal is hot, having been heated in a forge. Smithing can also involve the other aspects of metalworking, such as refining metals from their ores (traditionally done by smelting), casting it into shapes (foundry, founding), and file (tool), filing to shape and size. The prevalence of metalworking in the culture of recent centuries has led ''Smith (surname), Smith'' and its equivalents in various languages to be a common surname#Occupational name, occupational surname (German Schmidt (surname), Schmidt or Schmied, Portuguese Ferreiro, Ferreira (surname), Ferreira, French Lefèvre, Spanish Herrero, Italian Fabbr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanisms and machines wherever a component requires high strength; such forgings usually require further processing (such as machining) to achieve a finished part. Today, forging is a major worldwide industry. History Forging is one of the oldest known me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)