|

Flow Control Valve

A flow control valve regulates the flow or pressure of a fluid. Control valves normally respond to signals generated by independent devices such as flow meters or temperature gauges. Operation Control valves are normally fitted with actuators and positioners. Pneumatically-actuated globe valves and diaphragm valves are widely used for control purposes in many industries, although quarter-turn types such as (modified) ball and butterfly valves are also used. Control valves can also work with hydraulic actuators (also known as hydraulic pilots). These types of valves are also known as automatic control valves. The hydraulic actuators respond to changes of pressure or flow and will open/close the valve. Automatic control valves do not require an external power source, meaning that the fluid pressure is enough to open and close them. Automatic control valves include pressure reducing valves, flow control valves, back-pressure sustaining valves, altitude valves, and relief val ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin ''valva'', the moving part of a door, in turn from ''volvere'', to turn, roll. The simplest, and very ancient, valve is simply a freely hinged flap which swings down to obstruct fluid (gas or liquid) flow in one direction, but is pushed up by the flow itself when the flow is moving in the opposite direction. This is called a check valve, as it prevents or "checks" the flow in one direction. Modern control valves may regulate pressure or flow downstream and operate on sophisticated automation systems. Valves have many uses, including controlling water for irrigation, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gate Valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened. The gate faces can be parallel but are most commonly wedge-shaped (in order to be able to apply pressure on the sealing surface). Typical use Gate valves are used to shut off the flow of liquids rather than for flow regulation, which is frequently done with a globe valve. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low flow resistance. The size of the open flow path generally varies in a nonlinear manner as the gate is moved. This means that the flow rate does not change evenly with stem travel. Depending on the construction, a partially open gate can vibrate from the fluid flow. Gate valves are mostly used with larger pipe diameters (from 2" to the largest pipelines) since they are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Pressure Pipe Systems

Plastic pipe is a tubular section, or hollow cylinder, made of plastic. It is usually, but not necessarily, of circular cross-section, used mainly to convey substances which can flow—liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipes are far stiffer per unit weight than solid members. Plastic pipework is used for the conveyance of drinking water, waste water, chemicals, heating fluid and cooling fluids, foodstuffs, ultra-pure liquids, slurries, gases, compressed air, irrigation, plastic pressure pipe systems, and vacuum system applications. Types There are three basic types of plastic pipes: Solid wall pipe Extruded pipes consisting of one layer of a homogeneous matrix of thermoplastic material which is ready for use in a pipeline. Structured wall pipe Structured-wall pipes and fittings are products which have an optimized design with regard to material usage to achieve the physical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Needle Valve

A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates. Construction and operation An instrument needle valve uses a tapered pin to gradually open a space for fine control of flow. The flow can be controlled and regulated with the use of a spindle. A needle valve has a relatively small orifice with a long, tapered seat, and a needle-shaped plunger on the end of a screw, which exactly fits the seat. As the screw is turned and the plunger retracted, flow between the seat and the plunger is possible; however, until the plunger is completely retracted, the fluid flow is significantly impeded. Since it takes many turns of the fine-threaded screw to retract the plunger, precise regulation of the flow rate is easily possible. The virtue of the needle valve is from the vernier effect of the ratio between the needle's length and its diameter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mass Flow Controller

A mass flow controller (MFC) is a device used to measure and control the flow of liquids and gases. A mass flow controller is designed and calibrated to control a specific type of liquid or gas at a particular range of flow rates. The MFC can be given a setpoint from 0 to 100% of its full scale range but is typically operated in the 10 to 90% of full scale where the best accuracy is achieved. The device will then control the rate of flow to the given setpoint. MFCs can be either analog or digital. A digital flow controller is usually able to control more than one type of fluid whereas an analog controller is limited to the fluid for which it was calibrated. All mass flow controllers have an inlet port, an outlet port, a mass flow sensor and a proportional control valve. The MFC is fitted with a closed loop control system which is given an input signal by the operator (or an external circuit/computer) that it compares to the value from the mass flow sensor and adjusts the proporti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Globe Valve

A globe valve, different from ball valve, is a type of valve used for regulating flow in a pipeline, consisting of a movable plug or disc element and a stationary ring seat in a generally spherical body. Globe valves are named for their spherical body shape with the two halves of the ''body'' being separated by an internal baffle. This has an opening that forms a ''seat'' onto which a movable ''plug'' can be screwed in to close (or shut) the valve. The plug is also called a ''disc''. In globe valves, the plug is connected to a ''stem'' which is operated by screw action using a handwheel in manual valves. Typically, automated globe valves use smooth stems rather than threaded and are opened and closed by an actuator assembly. Information Although globe valves in the past had the spherical bodies which gave them their name, many modern globe valves do not have much of a spherical shape. However, the term ''globe valve'' is still often used for valves that have such an interna ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gate Valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened. The gate faces can be parallel but are most commonly wedge-shaped (in order to be able to apply pressure on the sealing surface). Typical use Gate valves are used to shut off the flow of liquids rather than for flow regulation, which is frequently done with a globe valve. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low flow resistance. The size of the open flow path generally varies in a nonlinear manner as the gate is moved. This means that the flow rate does not change evenly with stem travel. Depending on the construction, a partially open gate can vibrate from the fluid flow. Gate valves are mostly used with larger pipe diameters (from 2" to the largest pipelines) since they are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flow Measurement

Flow measurement is the quantification of bulk fluid movement. Flow can be measured in a variety of ways. The common types of flowmeters with industrial applications are listed below: * a) Obstruction type (differential pressure or variable area) * b) Inferential (turbine type) * c) Electromagnetic * d) Positive-displacement flowmeters, which accumulate a fixed volume of fluid and then count the number of times the volume is filled to measure flow. * e) Fluid dynamic (vortex shedding) * f) Anemometer * g) Ultrasonic * h) Mass flowmeter ( Coriolis force). Flow measurement methods other than positive-displacement flowmeters rely on forces produced by the flowing stream as it overcomes a known constriction, to indirectly calculate flow. Flow may be measured by measuring the velocity of fluid over a known area. For very large flows, tracer methods may be used to deduce the flow rate from the change in concentration of a dye or radioisotope. Kinds and units of measurement Both gas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flow Limiter

A flow limiter or flow restrictor is a device to restrict the flow of a fluid, in general a gas or a liquid. Some designs use single stage or multi stage orifice plates to handle high and low flow rates. Flow limiters are often used in manufacturing plants as well as households. Safety is usually the main purpose of using a flow limiter. An example is manufacturing facilities and laboratories using flow limiters to prevent injury or death from noxious gases that are in use. The flow limiter prevents gases from causing injury or death by reducing its cross-sectional area where gas flows. Uses * Reduce flow of fluid (velocity) through a system, e.g. to reduce water usage in a shower * Reduce the amount of gas passing through a system * Reduce pressure in a system * Applications in medical instrumentation * As a safety valve to provide limited flow after closing in the event of a broken hose. (See '' Hydraulic fuse''). Specifications *Orifice diameter *Flow tolerance *Media temperat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diaphragm Valve

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, an elastomeric diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve body may be constructed from plastic, metal, wood or other materials depending on the intended use. Categories There are two main categories of diaphragm valves: one type seals over a "weir" (saddle) and the other (sometimes called a "full bore or straight-through" valve) seals over a seat. In general, straight-through diaphragm valves are used in on-off applications and weir-type diaphragm valves are used for control or throttling applications. While diaphragm valves usually come in two-port forms (2/2-way diaphragm valve), they can also come with three ports (3/2-way diaphragm valves also called T-valves) and more (so called block-valves). When more than three ports are included, they generally require more than one diaphragm seat; however, special dual actuators can handle more port ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Control Valve

A control valve is a valve used to control fluid flow by varying the size of the flow passage as directed by a signal from a controller. This enables the direct control of flow rate and the consequential control of process quantities such as pressure, temperature, and liquid level. In automatic control terminology, a control valve is termed a "final control element". Operation The opening or closing of automatic control valves is usually done by electrical, hydraulic or pneumatic actuators. Normally with a modulating valve, which can be set to any position between fully open and fully closed, valve positioners are used to ensure the valve attains the desired degree of opening. Air-actuated valves are commonly used because of their simplicity, as they only require a compressed air supply, whereas electrically operated valves require additional cabling and switch gear, and hydraulically actuated valves required high pressure supply and return lines for the hydraulic fluid. The p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

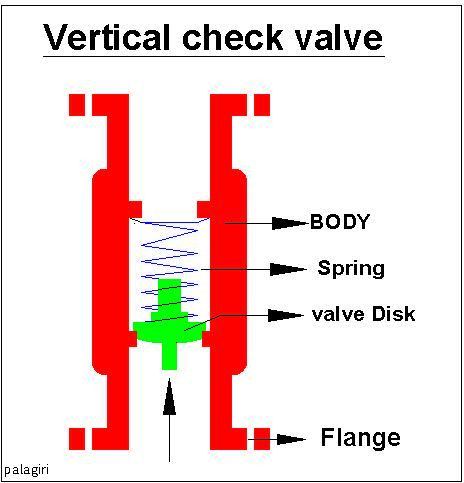

Check Valve

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, and inexpensive. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal. An important concept in check valves is the cracking pressure which is the minimum differential upstream pressure between inlet and outlet at which the valve will operate. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |