|

Ferrari Tipo 815

The Auto Avio Costruzioni 815 was the first car to be fully designed and built by Enzo Ferrari. Legal issues with former associates Alfa Romeo prevented Ferrari from creating the Ferrari marque. The 815 raced at the 1940 Brescia Grand Prix, where both entries failed to finish due to engine problems. One of the cars was later scrapped, while the other is currently in a car collection in Italy. Background In 1938, Ferrari left Alfa Romeo after running ''Scuderia Ferrari'' as their racing division. The agreement ending their association forbade Ferrari from restarting ''Scuderia Ferrari'' within the next four years. Ferrari then founded ''Auto Avio Costruzioni'' (AAC) in Modena to manufacture aircraft parts and machine tools for the Italian government. AAC specialized in the production of hydraulic grinding machines used to produce ball bearings. The company established business partnerships with other Italian firms, including Compagnia Nazionale Aeronautica and Piaggio. In Decemb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ferrari

Ferrari S.p.A. (; ) is an Italian luxury sports car manufacturer based in Maranello, Italy. Founded by Enzo Ferrari (1898–1988) in 1939 from the Alfa Romeo racing division as ''Auto Avio Costruzioni'', the company built its first car in 1940, and produced its first Ferrari-badged car in 1947. Fiat S.p.A. acquired 50% of Ferrari in 1969 and expanded its stake to 90% in 1988. In October 2014, Fiat Chrysler Automobiles (FCA) announced its intentions to separate Ferrari S.p.A. from FCA; as of the announcement FCA owned 90% of Ferrari. The separation began in October 2015 with a restructuring that established Ferrari N.V. (a company incorporated in the Netherlands) as the new holding company of the Ferrari S.p.A. group, and the subsequent sale by FCA of 10% of the shares in an IPO and concurrent listing of common shares on the New York Stock Exchange. Through the remaining steps of the separation, FCA's interest in Ferrari's business was distributed to shareholders of FCA, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alberto Massimino

Alberto Massimino (5 January 1895 – 27 November 1975) was an Italian automotive engineer. Biography Born in Turin, he studied mechanical engineering in Switzerland and worked for FIAT (1924–28), where he followed Vittorio Jano who had left for Alfa Romeo. The 1500 cc, 12-cylinder 806/504 was driven by Pietro Bordino in the Gran Premio di Milano (1927). He also had a short stay at Alfa Romeo and Stabilimenti Farina before joining Scuderia Ferrari (1938–44), working on the 158 Alfetta with Gioacchino Colombo, as well as on the Tipo 815 (1940 Mille Miglia). At Maserati (1944–52) he was involved in the Maserati 4CLT, Maserati A6 (1946) and Maserati 250F (1952). He then worked for on shorter projects for Ferrari (the Jano V12 and Dino), Stanguellini, De Tomaso, Moretti and Scuderia Serenissima Scuderia Serenissima and Scuderia SSS Republica di Venezia were names used by Giovanni Volpi to enter his own cars in Formula One and sports car racing in the early 1960s. Sc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leaf Spring

A leaf spring is a simple form of spring commonly used for the suspension in wheeled vehicles. Originally called a ''laminated'' or ''carriage spring'', and sometimes referred to as a semi-elliptical spring, elliptical spring, or cart spring, it is one of the oldest forms of vehicle suspension. A leaf spring is one or more narrow, arc-shaped, thin plates which are attached to the axle and chassis in a way that allows the leaf spring to flex vertically in response to irregularities in the road surface. Lateral leaf springs are the most commonly used arrangement, running the length of the vehicle and mounted perpendicular to the wheel axle, but numerous examples of transverse leaf springs exist as well. Leaf springs can serve multiple suspension functions: location, springing, and to some extent damping as well, through interleaf friction. However, this friction is not well controlled, resulting in stiction and irregular suspension motions. For this reason, some manufacturers have ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Live Axle

A beam axle, rigid axle or solid axle is a dependent suspension design in which a set of wheels is connected laterally by a single beam or shaft. Beam axles were once commonly used at the rear wheels of a vehicle, but historically they have also been used as front axles in four-wheel-drive vehicles. In most automobiles, beam axles have been replaced with front and rear independent suspensions. Implementation With a beam axle the camber angle between the wheels is the same no matter where it is in the travel of the suspension. A beam axle's fore & aft location is constrained by either: trailing arms, semi-trailing arms, radius rods, or leaf springs. The lateral location can be constrained by a Panhard rod, a Scott Russell linkage or a Watt's linkage, or some other arrangement, most commonly by the leaf springs. Shock absorbers and either leaf springs, coil springs, or air bags are used to control vertical movement. The Twist-beam rear suspension is a similar suspension desig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shock Absorber

A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated. Most shock absorbers are a form of dashpot (a damper which resists motion via viscous friction). Description Pneumatic and hydraulic shock absorbers are used in conjunction with cushions and springs. An automobile shock absorber contains spring-loaded check valves and orifices to control the flow of oil through an internal piston (see below). One design consideration, when designing or choosing a shock absorber, is where that energy will go. In most shock absorbers, energy is converted to heat inside the viscous fluid. In hydraulic cylinders, the hydraulic fluid heats up, while in air cylinders, the hot air is usually exhausted to the atmosphere. In other types of shock absorbers, such as electromagnetic types, the dissipated energy can be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dubonnet Suspension

Dubonnet suspension was a system of leading arm independent front suspension and steering popular mainly in the 1930s and 1940s. Not very durable unless exactingly maintained, it was soon replaced by other designs. It consisted of a rigidly mounted axle beam from which the sprung steering and suspension arms pivoted around kingpins mounted on the ends of the axle. The wheels themselves were mounted onto stub axles, suspended by self-contained suspension units outboard of the kingpins. The system featured an encased coil spring and shock absorber, which sealed in the oil needed to lubricate and protect the suspension parts. This was also the weakness of the layout, as any leaks would have negative effects on ride and durability. One advantage for a comfortable ride was the reduction in unsprung weight, as the kingpins and steering gear were inboard of the suspension, and not thus counted as sprung mass. This in turn led to 'synchronous' behaviour in many cars with this suspension, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

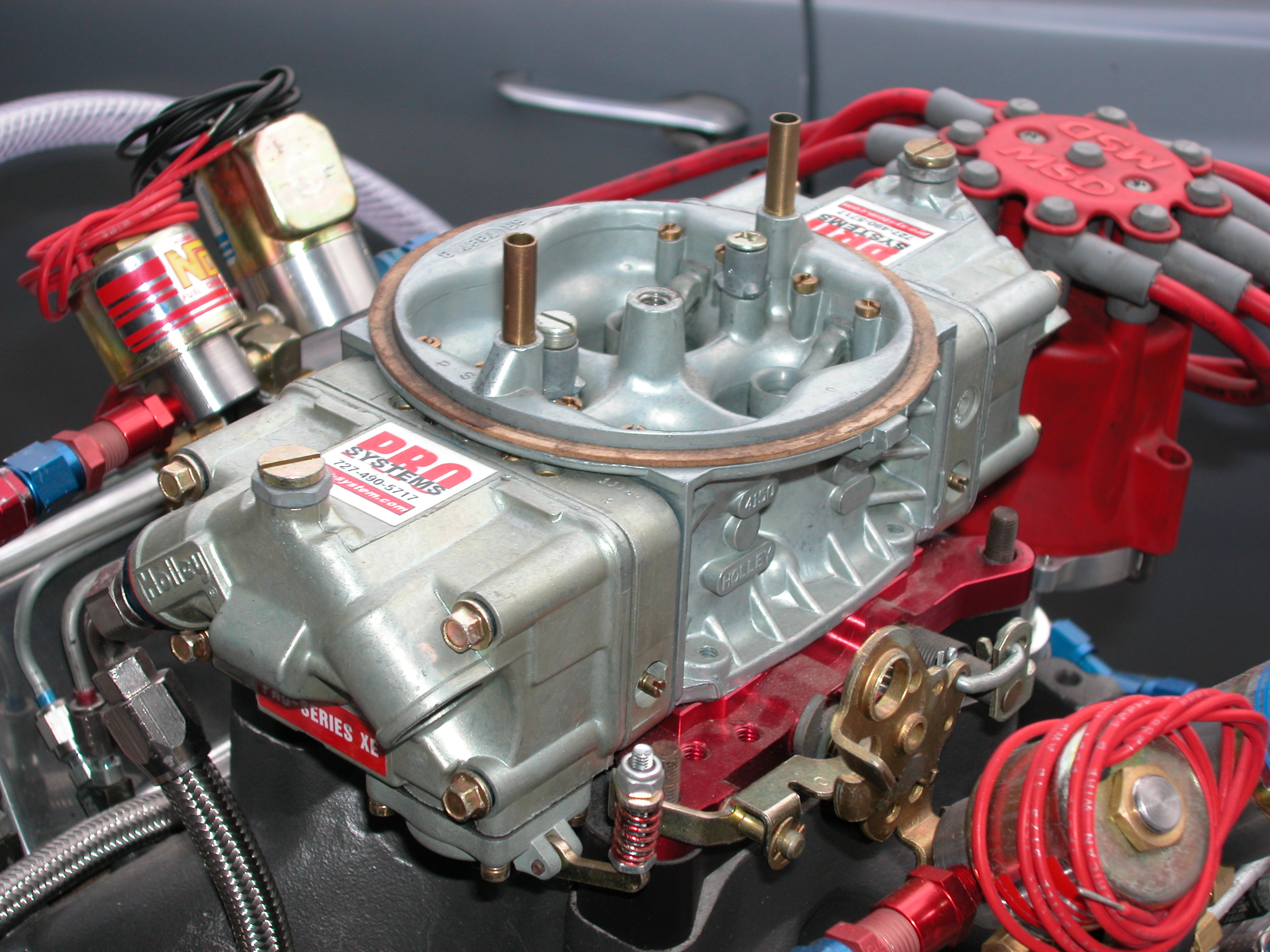

Carburettor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main metering circuit, however various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, however carburetors are still used by some small engines (e.g. lawnmowers, generators and concrete mixers) and motorcycles. Diesel engines have always used fuel injection instead of carburetors. Etymology The name "carburetor" is derived from the verb ''carburet'', which means "to combine with carbon," or in particular, "to enrich a gas by combining it with carbon or hydrocarbons." Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG). The name is spelled "carburetor" in American English a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weber Carburetor

Weber Carburetors is an automotive manufacturing company founded in 1923, known for their carburetors. History Eduardo Weber began his automotive career working for Fiat, first at their Turin plant (in 1914) and later at a dealership in Bologna. After WWI, with gasoline prices high, he reached a certain success in selling conversion kits for running trucks on kerosene instead. The company was established as ''Fabbrica Italiana Carburatori Weber'' in 1923 when Weber produced carburetors as part of a conversion kit for Fiats. Weber pioneered the use of two-stage twin-barrel carburetors, with two venturis of different sizes (the smaller one for low-speed running and the larger one optimised for high-speed use). In the 1930s, Weber began producing twin-barrel carburetors for motor racing, where two barrels of the same size were used. These were arranged so that each cylinder of the engine had its own carburetor barrel. These carburetors found use in Maserati and Alfa Romeo racin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dry Sump

A dry-sump system is a method to manage the lubricating motor oil in four-stroke and large two-stroke piston driven internal combustion engines. The dry-sump system uses two or more oil pumps and a separate oil reservoir, as opposed to a conventional wet-sump system, which uses only the main sump (U.S.: oil pan) below the engine and a single pump. A dry-sump engine requires a pressure relief valve to regulate negative pressure inside the engine, so internal seals are not inverted. Dry-sumps are common on larger diesel engines such as those used in ships, as well as gasoline engines used in racing cars, aerobatic aircraft, high-performance personal watercraft and motorcycles. Dry sump lubrication may be chosen for these applications due to increased reliability, oil capacity, reduction of oil starvation under high g-loads and/or other technical or performance reasons. Dry sump systems may not be suitable for all applications due to increased cost, complexity, and/or bulk, am ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cam-in-block

{{set index ...

A cam-in-block engine is where the camshaft is located in the engine block. Types of cam-in-block engines are: * F-Head Engine * Flathead engine * Overhead valve engine (the only type where the valves are above the combustion chamber) * T-head engine A T-head engine is an early type of internal combustion engine that became obsolete after World War I. It is a sidevalve engine that is distinguished from the much more common L-head by its placement of the valves. The intake valves are on one ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Distributor

A distributor is an enclosed rotating switch used in spark-ignition internal combustion engines that have mechanically timed ignition. The distributor's main function is to route high voltage current from the ignition coil to the spark plugs in the correct firing order, and for the correct amount of time. Except in magneto systems and many modern computer controlled engines that use crank angle/position sensors, the distributor also houses a mechanical or inductive breaker switch to open and close the ignition coil's primary circuit. The first reliable battery operated ignition was the Delco ignition system developed by Dayton Engineering Laboratories Co. (Delco) and introduced in the 1910 Cadillac Model 30. This ignition was developed by Charles Kettering and was considered a wonder in its day. Atwater Kent invented his Unisparker ignition system about this time in competition with the Delco system. By the end of the 20th century mechanical ignitions were disappearing from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight-eight Engine

The straight-eight engine (also referred to as an inline-eight engine; abbreviated I8 or L8) is a piston engine with eight cylinders arranged in a straight line along the crankshaft. The number of cylinders and perfect primary and secondary engine balance resulted in smooth running, however there are several downsides relating to the significant length of the engine. Straight-eight engines were popular in luxury cars and racing cars in the 1920s to 1940s. During the 1950s, straight-eight engines were largely replaced by the more compact V8 engine design. Design A straight-eight can achieve perfect primary balance and secondary balance if an appropriate firing order is used. Like most other engines, torsional vibration of the crankshaft requires that a harmonic damper is installed on the crankshaft. at the accessory end of the crankshaft. As per other engines with 8 cylinders, the power delivery is smoother than engines with fewer cylinders. In the early 20th century, these sm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)