|

Electronically-controlled Unit Injector

An electronically controlled unit injector (EUI) is a unit injector (UI) with electronic control. It performs the same function as a conventional unit injector in an internal combustion engine, such as in an on-road or off-road vehicle or a diesel-electric locomotive. The pressurized delivery of fuel is camshaft-driven, but the timing of the injector's internal operations are controlled by the engine control unit so as to achieve certain advantages. Advantages * Maximum horsepower, within the applicable emissions tier * Minimum emissions, possibly at the expense of slightly increased fuel consumption * Minimum fuel consumption, possibly at the expense of slightly increased emissions * Optimum vehicle performance Construction Central to the EUI is the built-in plunger pump, which, just as in a UI, allows for low-pressure fuel delivery and return to all injectors, yet provides exceptionally high pressure and concomitant injection and atomization of the fuel to a cylinder during t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons ( piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle ( jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel-electric Locomotive

A diesel locomotive is a type of railway locomotive in which the prime mover (locomotive), prime mover is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels. Early internal combustion engine, internal combustion locomotives and railcars used kerosene and gasoline as their fuel. Rudolf Diesel patented his first compression-ignition engine in 1898, and steady improvements to the design of diesel engines reduced their physical size and improved their power-to-weight ratios to a point where one could be mounted in a locomotive. Internal combustion engines only operate efficiently within a limited power band, and while low power gasoline engines could be coupled to mechanical transmission (mechanics), transmissions, the more powerful diesel engines required the development of new forms of transmission. This is because clutches would need to be very large at these power le ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams, in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han Dynasty in China, and they were widespread by the medieval period. The camshaft was described in 1206 by engineer Al-Jazari. He employed it as part of his automata, water-raising machines, and water clocks such as the castle clock. Once the rotative version of the steam engine was developed in the late 18th century, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Control Unit

An engine control unit (ECU), also commonly called an engine control module (ECM), is a type of electronic control unit that controls a series of actuators on an internal combustion engine to ensure optimal engine performance. It does this by reading values from a multitude of sensors within the engine bay, interpreting the data using multidimensional performance maps (called lookup tables), and adjusting the engine actuators. Before ECUs, air–fuel mixture, ignition timing, and idle speed were mechanically set and dynamically controlled by mechanical and pneumatic means. If the ECU has control over the fuel lines, then it is referred to as an electronic engine management system (EEMS). The fuel injection system has the major role of controlling the engine's fuel supply. The whole mechanism of the EEMS is controlled by a stack of sensors and actuators. Workings Control of air–fuel ratio Most modern engines use some type of fuel injection to deliver fuel to the cylinders. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

United States Emission Standards

United States vehicle emission standards are set through a combination of legislative mandates enacted by Congress through Clean Air Act (CAA) amendments from 1970 onwards, and executive regulations managed nationally by the Environmental Protection Agency (EPA), and more recently along with the National Highway Traffic Safety Administration (NHTSA). These standard cover common motor vehicle air pollution, including carbon monoxide, nitrogen oxides, and particulate emissions, and newer versions have incorporated fuel economy standards. In nearly all cases, these agencies set standards that are expected to be met on a fleet-wide basis from automobile and other vehicle manufacturers, with states delegated to enforce those standards but not allowed to set stricter requirements. California has generally been the exception, having been granted a waiver and given allowance to set stricter standards as it had established its own via the California Air Resources Board prior to the 1970 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

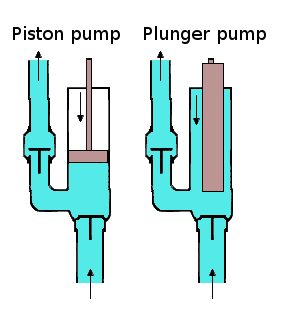

Plunger Pump

A plunger pump is a type of positive displacement pump where the high-pressure seal is stationary and a smooth cylindrical plunger slides through the seal. This makes them different from piston pumps and allows them to be used at higher pressures. This type of pump is often used to transfer municipal and industrial sewage. History The invention of the plunger pump is attributed to Samuel Morland based on a patent of 1675. Operation Piston pumps and plunger pumps are positive displacement pumps that use a plunger or piston to move media through a cylindrical chamber. The plunger or piston is actuated by a steam powered, pneumatic, hydraulic, or electric drive. Rotary piston and plunger pumps use a crank mechanism to create a reciprocating motion along an axis, which then builds pressure in a cylinder or working barrel to force gas or fluid through the pump. The pressure in the chamber actuates the valves at both the suction and discharge points. Plunger pumps are used in appli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electro-Motive Diesel

Progress Rail Locomotives, doing business as Electro-Motive Diesel (EMD), is an American manufacturer of diesel-electric locomotives, locomotive products and diesel engines for the rail industry. The company is owned by Caterpillar through its subsidiary Progress Rail. Electro-Motive Diesel traces its roots to the Electro-Motive Engineering Corporation, a designer and marketer of gasoline-electric self-propelled rail cars founded in 1922 and later renamed Electro-Motive Company (EMC). In 1930, General Motors purchased Electro-Motive Company and the Winton Engine Co., and in 1941 it expanded EMC's realm to locomotive engine manufacturing as Electro-Motive Division (EMD). In 2005, GM sold EMD to Greenbriar Equity Group and Berkshire Partners, which formed Electro-Motive Diesel to facilitate the purchase. In 2010, Progress Rail completed the purchase of Electro-Motive Diesel from Greenbriar, Berkshire, and others. EMD's headquarters, engineering facilities and parts manufacturing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

EMD 710

The EMD 710 is a line of diesel engines built by Electro-Motive Diesel (previously General Motors' Electro-Motive Division). The 710 series replaced the earlier EMD 645 series when the 645F series proved to be unreliable in the early 1980s 50-series locomotives which featured a maximum engine speed of 950 rpm.40-series versions of the 645, save the initial teething problems with the 20-645E, which were eventually resolved, proved to be exceptionally reliable. The EMD 710 is a relatively large medium-speed two-stroke diesel engine that has displacement per cylinder, and a maximum engine speed of 900 rpm.Same parts suitable for 1000 rpm speed, yet rated lower because of earlier problems in EMD 645. Factory-fitted governor limits to 900 rpm. In 1951, E. W. Kettering wrote a paper for the ASME entitled, ''History and Development of the 567 Series General Motors Locomotive Engine'', which goes into great detail about the technical obstacles that were encountered during the developmen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |