|

Edge Dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to slide over each other at low stress levels and is known as ''glide'' or slip. The crystalline order is restored on either side of a ''glide dislocation'' but the atoms on one side have moved by one position. The crystalline order is not fully restored with a ''partial dislocation''. A dislocation defines the boundary between ''slipped'' and ''unslipped'' regions of material and as a result, must either form a complete loop, intersect other dislocations or defects, or extend to the edges of the crystal. A dislocation can be characterised by the distance and direction of movement it causes to atoms which is defined by the Burgers vector. Plastic deformation of a material occurs by the creation and movement of many dislocations. The number and a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burgers Vector And Dislocations (screw And Edge Type)

Burger or Burgers may refer to: Food and drink Foods * Hamburger, a sandwich consisting of one or more cooked beef patties, placed inside a sliced bread roll or bun roll. ** Cheeseburger, a hamburger with added cheese(s) * Ground beef, minced beef used to make hamburgers ** Patty, a portion of ground meat, often round, used to make burgers * Steak burger, a burger consisting of steak * Rice burger, uses compressed rice cakes instead of hamburger buns * Turkey burger, a burger involving a deli turkey or a turkey patty * Veggie burger, a burger made with plant-based meat substitute * Afghani burger, an Afghan fast food wrap consisting of a piece of Afghan bread rolled around french fries, along with chutney and other condiments, vegetables, and often sausages or other meat. Drinks * Burger (grape), a Californian wine grape * Gouais blanc, a French wine grape that is also known as Burger * Elbling, a German wine grape that is also known as Burger People * Burger (surname) * Bur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Stress

Shear stress, often denoted by (Greek: tau), is the component of stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. ''Normal stress'', on the other hand, arises from the force vector component perpendicular to the material cross section on which it acts. General shear stress The formula to calculate average shear stress is force per unit area.: : \tau = , where: : = the shear stress; : = the force applied; : = the cross-sectional area of material with area parallel to the applied force vector. Other forms Wall shear stress Wall shear stress expresses the retarding force (per unit area) from a wall in the layers of a fluid flowing next to the wall. It is defined as: \tau_w:=\mu\left(\frac\right)_ Where \mu is the dynamic viscosity, u the flow velocity and y the distance from the wall. It is used, for example, in the description of arterial blood flow in which case which ther ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Simulation Of Dislocations In Aluminium

A simulation is the imitation of the operation of a real-world process or system over time. Simulations require the use of models; the model represents the key characteristics or behaviors of the selected system or process, whereas the simulation represents the evolution of the model over time. Often, computers are used to execute the simulation. Simulation is used in many contexts, such as simulation of technology for performance tuning or optimizing, safety engineering, testing, training, education, and video games. Simulation is also used with scientific modelling of natural systems or human systems to gain insight into their functioning, as in economics. Simulation can be used to show the eventual real effects of alternative conditions and courses of action. Simulation is also used when the real system cannot be engaged, because it may not be accessible, or it may be dangerous or unacceptable to engage, or it is being designed but not yet built, or it may simply not ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cold Working

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature. Such processes are contrasted with hot working techniques like hot rolling, forging, welding, etc. The same or similar terms are used in glassmaking for the equivalents; for example cut glass is made by "cold work", cutting or grinding a formed object. Cold forming techniques are usually classified into four major groups: squeezing, bending, drawing, and shearing. They generally have the advantage of being simpler to carry out than hot working techniques. Unlike hot working, cold working causes the crystal grains and inclusions to distort following the flow of the metal; which may cause work hardening and anisotropic material properties. Work hardening makes the metal harder, stiffer, and stronger, but less plastic, and may cause cracks of the piece. The possible uses of cold forming are extremely v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity (optics), opacity, and lustre (mineralogy), luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength. Alloys are defined by a metallic bonding character. The alloy constituents are usually measured by mass percentage for practical applications, and in Atomic ratio, atomic fraction for basic science studies. Alloys are usually classified as substitutional or interstitial alloys, depending on the atomic arrangement that forms the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Treating

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term ''heat treatment'' applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding. Physical processes Metallic materials consist of a microstructure of small crystals called "gra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Strength

In materials science and engineering, the yield point is the point on a stress-strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation. The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. In some materials, such as aluminium, there is a gradual onset of non-linear behavior, making the precise yield point difficult to determine. In such a case, the offset yiel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardness

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion. In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as sodium and metallic tin, or wood and common plastics. Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, hardness can be measured in different ways, such as scratch hardness, indentation hardness, and rebound hardness. Hardness is dependent on ductility, elastic stiffness, plasticity, strain, strength, toughness, viscoelasticity, and viscosity. Common examples of hard matter are ceramics, concrete, certain metals, and superhard materials, which can be contrasted with soft matter. Measuring hardness There are three main types of hardness measurements: ''scratch' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductility

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stress before failure. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufacturing operations (such as cold working) and its capacity to absorb mechanical overload.. Some metals that are generally described as ductile include gold and copper. However, not all metals experience ductile failure as some can be characterized with brittle failure like cast iron. Polymers generally can be viewed as ductile materials as they typically allow for plastic deformation. Malleability, a similar mechanical property, is characterized by a material's ability to deform plastically without failure under compressive stress. Historically, materials were considered malleable if they were am ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grain Boundaries

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional crystallographic defect, defects in the crystal structure, and tend to decrease the electrical conductivity, electrical and thermal conductivity of the material. Most grain boundaries are preferred sites for the onset of corrosion and for the precipitation (chemistry), precipitation of new Phase (matter), phases from the solid. They are also important to many of the mechanisms of Creep (deformation), creep. On the other hand, grain boundaries disrupt the motion of dislocations through a material, so reducing crystallite size is a common way to improve mechanical strength, as described by the Hall–Petch relationship. High and low angle boundaries It is convenient to categorize grain boundaries according to the extent of misorientation between the two grains. ''Low-angle grain boundaries'' (''LAGB'') or ''subgrain boun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

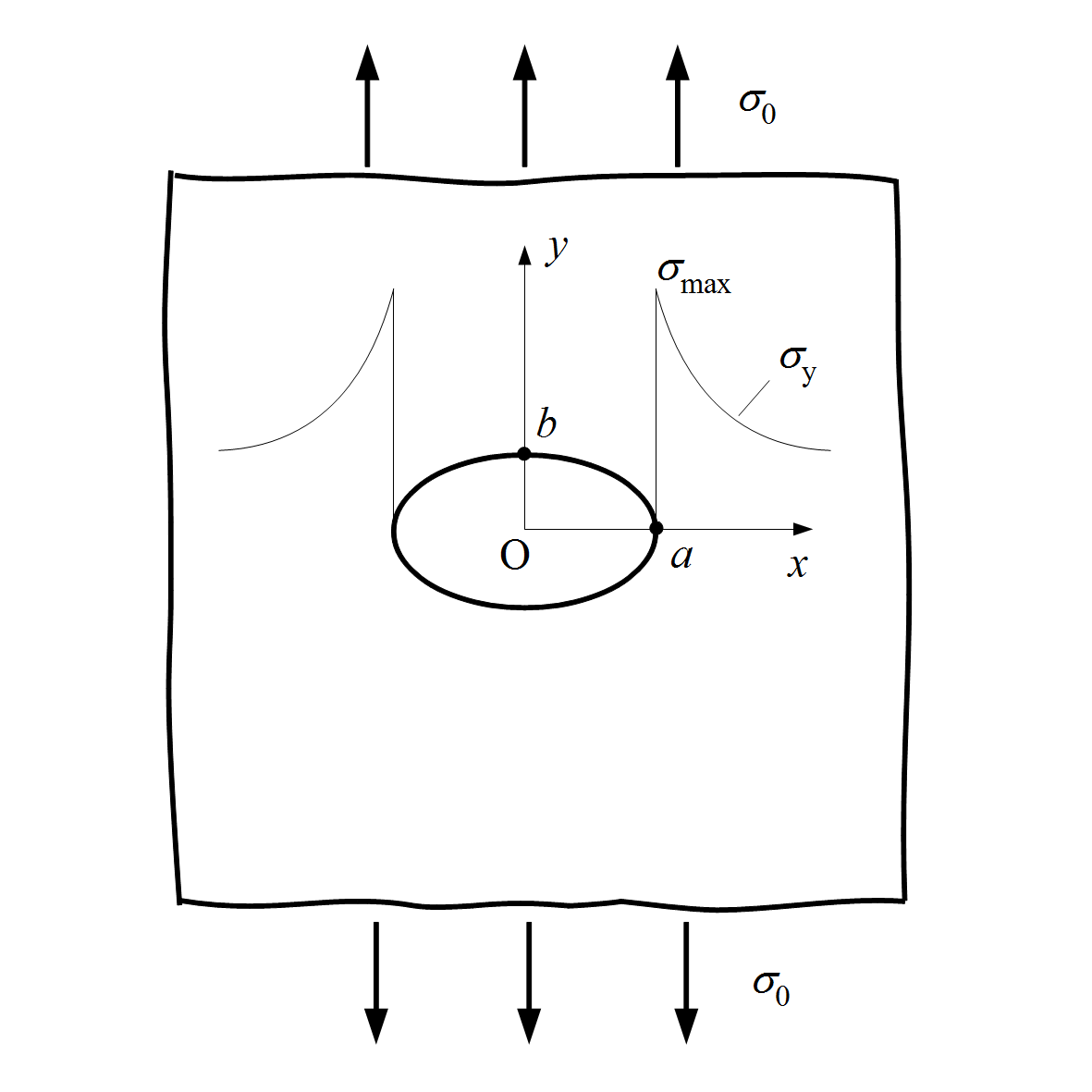

Stress Concentrations

In solid mechanics, a stress concentration (also called a stress raiser or a stress riser) is a location in an object where the stress is significantly greater than the surrounding region. Stress concentrations occur when there are irregularities in the geometry or material of a structural component that cause an interruption to the flow of stress. This arises from such details as holes, grooves, notches and fillets. Stress concentrations may also occur from accidental damage such as nicks and scratches. The degree of concentration of a discontinuity under typically tensile loads can be expressed as a non-dimensional stress concentration factor K_t, which is the ratio of the highest stress to the nominal far field stress. For a circular hole in an infinite plate, K_t = 3. The stress concentration factor should not be confused with the stress intensity factor, which is used to define the effect of a crack on the stresses in the region around a crack tip. For ductile materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrogen Embrittlement

Hydrogen embrittlement (HE), also known as hydrogen-assisted cracking or hydrogen-induced cracking (HIC), is a reduction in the ductility of a metal due to absorbed hydrogen. Hydrogen atoms are small and can permeate solid metals. Once absorbed, hydrogen lowers the stress required for cracks in the metal to initiate and propagate, resulting in embrittlement. Hydrogen embrittlement occurs most notably in steels, as well as in iron, nickel, titanium, cobalt, and their alloys. Copper, aluminium, and stainless steels are less susceptible to hydrogen embrittlement. The essential facts about the nature of hydrogen embrittlement have been known since the 19th century. Hydrogen embrittlement is maximised at around room temperature in steels, and most metals are relatively immune to hydrogen embrittlement at temperatures above 150 °C. Hydrogen embrittlement requires the presence of both atomic ("diffusible") hydrogen and a mechanical stress to induce crack growth, although that str ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |