|

Ethylene Bis(stearamide)

Ethylene bis stearamide (EBS) is an organic compound with the formula (CH2NHC(O)C17H35)2. It is a waxy white solid and is also found as powder or beads that is widely used as a form release agent. The compound is derived from the reaction of ethylenediamine and stearic acid. It is a white solid of low toxicity that provides a slippery coating for a variety of applications. Applications EBS is a synthetic wax used as a dispersing agent or internal/external lubricant for benefits in plastic applications to facilitate and stabilize the dispersion of solid compounding materials to enhance processability, to decrease friction and abrasion of the polymer surface, and to contribute color stability and polymer degradation. It is also used in process industries as release agent and antistatic agent An antistatic agent is a compound used for treatment of materials or their surfaces in order to reduce or eliminate buildup of static electricity. Static charge may be generated by the tr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stearamidopropyl Dimethylamine

Stearamidopropyl dimethylamine is an ingredient in some types of hair conditioner Hair conditioner is a hair care cosmetic product used to improve the feel, texture, appearance, and manageability of hair. Its main purpose is to reduce friction between strands of hair to allow smoother brushing or combing, which might otherwise .... It has antistatic, emulsifying, hair conditioning, and surfactant properties. It is water soluble, readily biodegradable, and mildly toxic to aquatic life. References External links * Fatty acid amides Cosmetics chemicals Dimethylamino compounds {{organic-compound-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Release Agent

A release agent (also mold release agent, release coating, or mold release coating) is a chemical used to prevent other materials from bonding to surfaces. It can provide a solution in processes involving mold release, die-cast release, plastic release, adhesive release, and tire and web release. Release agents provide the critical barrier between a molding surface and the substrate, facilitating separation of the cured part from the mold. Without such a barrier in place, the substrate would become fused to the mold surface, resulting in difficult clean-up and dramatic loss in production efficiency. Even when a release agent is used, factors such as irregular applications or improper release agent choice may have a dramatic effect on the quality and consistency of the finished product. Many kinds of release agents are used. They are waxes, fatty ester, silicones, and metallic soaps. 420 px, Magnesium stearate is a release agent. Functionality Cosolvent Volatile organic compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ethylenediamine

Ethylenediamine (abbreviated as en when a ligand) is the organic compound with the formula C2H4(NH2)2. This colorless liquid with an ammonia-like odor is a basic amine. It is a widely used building block in chemical synthesis, with approximately 500,000 tonnes produced in 1998.Karsten Eller, Erhard Henkes, Roland Rossbacher, Hartmut Höke "Amines, Aliphatic" in Ullmann's Encyclopedia of Industrial Chemistry, 2005 Wiley-VCH Verlag, Weinheim. Ethylenediamine is the first member of the so-called polyethylene amines. Synthesis Ethylenediamine is produced industrially by treating 1,2-dichloroethane with ammonia under pressure at 180 °C in an aqueous medium:Hans-Jürgen Arpe, Industrielle Organische Chemie, 6. Auflage (2007), Seite 245, Wiley VCH : In this reaction hydrogen chloride is generated, which forms a salt with the amine. The amine is liberated by addition of sodium hydroxide and can then be recovered by . Diethylenetriamine (DETA) and triethylenetetramine (TETA) a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stearic Acid

Stearic acid ( , ) is a saturated fatty acid with an 18-carbon chain. The IUPAC name is octadecanoic acid. It is a waxy solid and its chemical formula is C17H35CO2H. Its name comes from the Greek word στέαρ "''stéar''", which means tallow. The salts and esters of stearic acid are called stearates. As its ester, stearic acid is one of the most common saturated fatty acids found in nature following palmitic acid.Gunstone, F. D., John L. Harwood, and Albert J. Dijkstra "The Lipid Handbook with Cd-Rom. 3rd ed. Boca Raton: CRC Press, 2007. , The triglyceride derived from three molecules of stearic acid is called stearin. Occurrence and production Stearic acid is more abundant in animal fat (up to 30%) than in vegetable fat (typically <5%). The important exceptions are the foods (34%) and [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dispersing Agent

A dispersant or a dispersing agent is a substance, typically a surfactant, that is added to a suspension of solid or liquid particles in a liquid (such as a colloid or emulsion) to improve the separation of the particles and to prevent their settling or clumping. Dispersants are widely used to stabilize various industrial and artisanal products, such as paints, ferrofluids, and salad dressings. The plasticizers or superplasticizers, used to improve the workability of pastes like concrete and clay, are typically dispersants. The concept also largely overlaps with that of detergent, used to bring oily contamination into water suspension, and of emulsifier, used to create homogeneous mixtures of immiscible liquids like water and oil. Natural suspensions like milk and latex contain substances that act as dispersants. Applications Automotive Automotive engine oils contain both detergents and dispersants. Metallic-based detergents prevent the accumulation of varnish like deposits on t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lubricant

A lubricant (sometimes shortened to lube) is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, transporting foreign particles, or heating or cooling the surfaces. The property of reducing friction is known as lubricity. In addition to industrial applications, lubricants are used for many other purposes. Other uses include cooking (oils and fats in use in frying pans, in baking to prevent food sticking), bioapplications on humans (e.g. lubricants for artificial joints), ultrasound examination, medical examination, and sexual intercourse. It is mainly used to reduce friction and to contribute to a better and efficient functioning of a mechanism. History Lubricants have been in some use for thousands of years. Calcium soaps have been identified on the axles of chariots dated to 1400 BC. Building stones were slid on oil-impregrated lumb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction: *Dry friction is a force that opposes the relative lateral motion of two solid surfaces in contact. Dry friction is subdivided into ''static friction'' ("stiction") between non-moving surfaces, and ''kinetic friction'' between moving surfaces. With the exception of atomic or molecular friction, dry friction generally arises from the interaction of surface features, known as asperities (see Figure 1). *Fluid friction describes the friction between layers of a viscous fluid that are moving relative to each other. *Lubricated friction is a case of fluid friction where a lubricant fluid separates two solid surfaces. *Skin friction is a component of drag, the force resisting the motion of a fluid across the surface of a body. *Internal friction is the force resisting motion between the elements making up a so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasion (mechanical)

Abrasion is the process of scuffing, scratching, wearing down, marring, or rubbing away. It can be intentionally imposed in a controlled process using an abrasive. Abrasion can be an undesirable effect of exposure to normal use or exposure to the elements. In stone shaping Ancient artists, working in stone, used abrasion to create sculptures. The artist selected dense stones like carbonite and emery and rubbed them consistently against comparatively softer stones like limestone and granite. The artist used different sizes and shapes of abrasives, or turned them in various ways as they rubbed, to create effects on the softer stone's surface. Water was continuously poured over the surface to carry away particles. Abrasive technique in stone shaping was a long, tedious process that, with patience, resulted in eternal works of art in stone. Models The Archard equation is a simple model used to describe sliding wear and is based on the theory of asperity contact. Q = \frac H whe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer

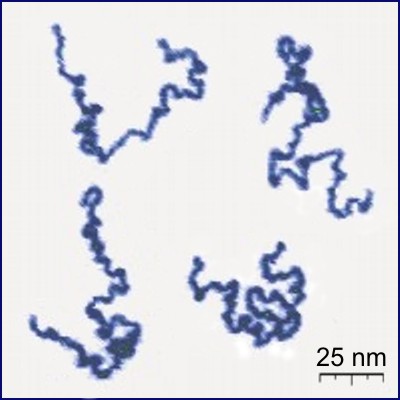

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part") is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals. The term "polymer" derives from the Greek word πολύς (''polus'', meaning "many, much") and μέρος (''meros'' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Degradation

Polymer degradation is the reduction in the physical properties of a polymer, such as strength, caused by changes in its chemical composition. Polymers and particularly plastics are subject to degradation at all stages of their product life cycle, including during their initial processing, use, disposal into the environment and recycling. The rate of this degradation varies significantly; biodegradation can take decades, whereas some industrial processes can completely decompose a polymer in hours. Technologies have been developed to both inhibit or promote degradation. For instance, polymer stabilizers ensure plastic items are produced with the desired properties, extend their useful lifespans, and facilitate their recycling. Conversely, biodegradable additives accelerate the degradation of plastic waste by improving its biodegradability. Some forms of plastic recycling can involve the complete degradation of a polymer back into monomers or other chemicals. In general, the effec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Industries

Process manufacturing is a branch of manufacturing that is associated with formulas and manufacturing recipes,Difference Between Discrete and Process Manufacturing BatchMaster Blog. and can be contrasted with discrete manufacturing, which is concerned with discrete units, bills of materials and the assembly of components. Process manufacturing is also referred to as a 'process industry' which is defined as an industry, such as the chemical or petrochemical industry, that is concerned with the processing of bulk resources into other products. Process manufacturing is commonWhat i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Antistatic Agent

An antistatic agent is a compound used for treatment of materials or their surfaces in order to reduce or eliminate buildup of static electricity. Static charge may be generated by the triboelectric effect or by a non-contact process using a high voltage power source. Static charge may be introduced on a surface as part of an in-mold label printing process. The role of an antistatic agent is to make the surface or the material itself slightly conductive, either by being conductive itself, or by absorbing moisture from the air; therefore, some humectants can be used. The molecules of an antistatic agent often have both hydrophilic and hydrophobic areas, similar to those of a surfactant; the hydrophobic side interacts with the surface of the material, while the hydrophilic side interacts with the air moisture and binds the water molecules. Internal antistatic agents are designed to be mixed directly into the material, external antistatic agents are applied to the surface. Common ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |