|

Engineer's Blue

Engineer's blue (also known as scraping blue, Prussian blue, or simply bluing) is a highly pigmented paste used to assist in the mating of two or more components. History Joseph Whitworth popularized the first practical method of making accurate flat surfaces, during the 1830s, by using engineer's blue and scraping techniques on three trial surfaces. Prior to his scraping technique, the same three plate method was employed using polishing techniques, giving less accurate results. This improvement led to an explosion of development of precision instruments using these flat surface generation techniques as a basis for further construction of precise shapes. Preparation Engineer's blue is prepared by mixing Prussian blue with a non-drying oily material (for example, grease). The coloured oil is rubbed onto a reference surface, and the workpiece is then rubbed against the coloured reference; the transfer (by contact) of the pigment indicates the position of high spots on the work ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joseph Whitworth

Sir Joseph Whitworth, 1st Baronet (21 December 1803 – 22 January 1887) was an English engineer, entrepreneur, inventor and philanthropist. In 1841, he devised the British Standard Whitworth system, which created an accepted standard for screw threads. Whitworth also created the Whitworth rifle, often called the "sharpshooter" because of its accuracy, which is considered one of the earliest examples of a sniper rifle. Whitworth was created a baronet by Queen Victoria in 1869. Upon his death in 1887, Whitworth bequeathed much of his fortune for the people of Manchester, with the Whitworth Art Gallery and Christie Hospital partly funded by Whitworth's money. Whitworth Street and Whitworth Hall in Manchester are named in his honour. Whitworth's company merged with the W.G. Armstrong & Mitchell Company to become Armstrong Whitworth in 1897. Biography Early life Whitworth was born in John Street, Stockport, Cheshire, where the Stockport Courthouse is today. The site is marked b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hand Scraper

A hand scraper is a single-edged tool used to scrape metal or other materials from a surface. This may be required where a surface needs to be trued, corrected for fit to a mating part, needs to retain oil (usually on a freshly ground surface), or to give a decorative finish. Surface plates were traditionally made by scraping. Three raw (plates that have been `seasoned` or residual stress relieved and received suitable surface treatments, but unfinished) cast surface plates, a flat scraper (as pictured at the top of the image) and a quantity of bearing blue (or red lead) were all that was required in the way of tools. The scraper in the center of the image is a three corner scraper and is typically used to deburr holes or the internal surface of bush type bearings. Bushes are typically made from bronze or a white metal. The scraper pictured at the bottom is a curved scraper. It has a slight curve in its profile and is also suitable for bush bearings, typically the longe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Plate

A surface plate is a solid, flat plate used as the main horizontal reference plane for precision inspection, marking out (layout), and tooling setup. The surface plate is often used as the baseline for all measurements to a workpiece, therefore one primary surface is finished extremely flat with tolerances below per 2960 mm for a grade 0 plate. Surface plates are a common tool in the manufacturing industry and are often fitted with mounting points so that it can be an integrated structural element of a machine such as a coordinate-measuring machine, precision optical assembly, or other high precision scientific & industrial machine. Plates are typically square or rectangular, although they may be cut to any shape. Accuracy and grade There are varying grades used to describe the accuracy of some metrology equipment such as: AA, A, B, and Workshop grade. While workshop grade is the least accurate, all grades of surface plates are held to a high degree of flatness. Surface plates ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Prussian Blue

Prussian blue (also known as Berlin blue, Brandenburg blue or, in painting, Parisian or Paris blue) is a dark blue pigment produced by oxidation of ferrous ferrocyanide salts. It has the chemical formula Fe CN)">Cyanide.html" ;"title="e(Cyanide">CN) Turnbull's blue is chemically identical, but is made from different reagents, and its slightly different color stems from different impurities and particle sizes. Prussian blue was the first modern synthetic pigment. It is prepared as a very fine colloidal dispersion, because the compound is not soluble in water. It contains variable amounts of other ions and its appearance depends sensitively on the size of the colloidal particles. The pigment is used in paints, and it is the traditional "blue" in blueprints, and became prominent in 19th-century () Japanese woodblock prints. In medicine, orally administered Prussian blue is used as an antidote for certain kinds of heavy metal poisoning, e.g., by thallium(I) and radioactive is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grease (lubricant)

Grease is a solid or semisolid lubricant formed as a dispersion of thickening agents in a liquid lubricant. Grease generally consists of a soap emulsified with mineral or vegetable oil. A common feature of greases is that they possess a high initial viscosity, which upon the application of shear, drops to give the effect of an oil-lubricated bearing of approximately the same viscosity as the base oil used in the grease. This change in viscosity is called shear thinning. Grease is sometimes used to describe lubricating materials that are simply soft solids or high viscosity liquids, but these materials do not exhibit the shear-thinning properties characteristic of the classical grease. For example, petroleum jellies such as Vaseline are not generally classified as greases. Greases are applied to mechanisms that can be lubricated only infrequently and where a lubricating oil would not stay in position. They also act as sealants to prevent ingress of water and incompressible materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flatness (manufacturing)

In manufacturing and mechanical engineering, flatness is an important geometric condition for workpieces and tools. In the manufacture of precision parts and assemblies, especially where parts will be required to be connected across a surface area in an air-tight or liquid-tight manner, flatness is a critical quality of the manufactured surfaces. Such surfaces are usually machined or ground to achieve the required degree of flatness. High-definition metrology, such as digital holographic interferometry, of such a surface to confirm and ensure that the required degree of flatness has been achieved is a key step in such manufacturing processes. Flatness may be defined in terms of least squares fit to a plane ("statistical flatness"), worst-case or overall flatness (the distance between the two closest parallel planes within). Two parts that are flat to about 1 helium light band (HLB) can be "wrung" together, which means they will cling to each other when placed in contact. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing Assembly

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may ''prevent'' a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts. Rotary bearings hold rotating components such as shafts or axles within mechanical systems, and transfer axial and radial loads from the source of the load to the structure supporting it. The simplest form of bearing, the ''plain bearing'', consists of a shaft rotating in a hole. Lubrication is used to reduce friction. In the ''ball bearing'' and ''roller bearing'', to reduce sliding ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

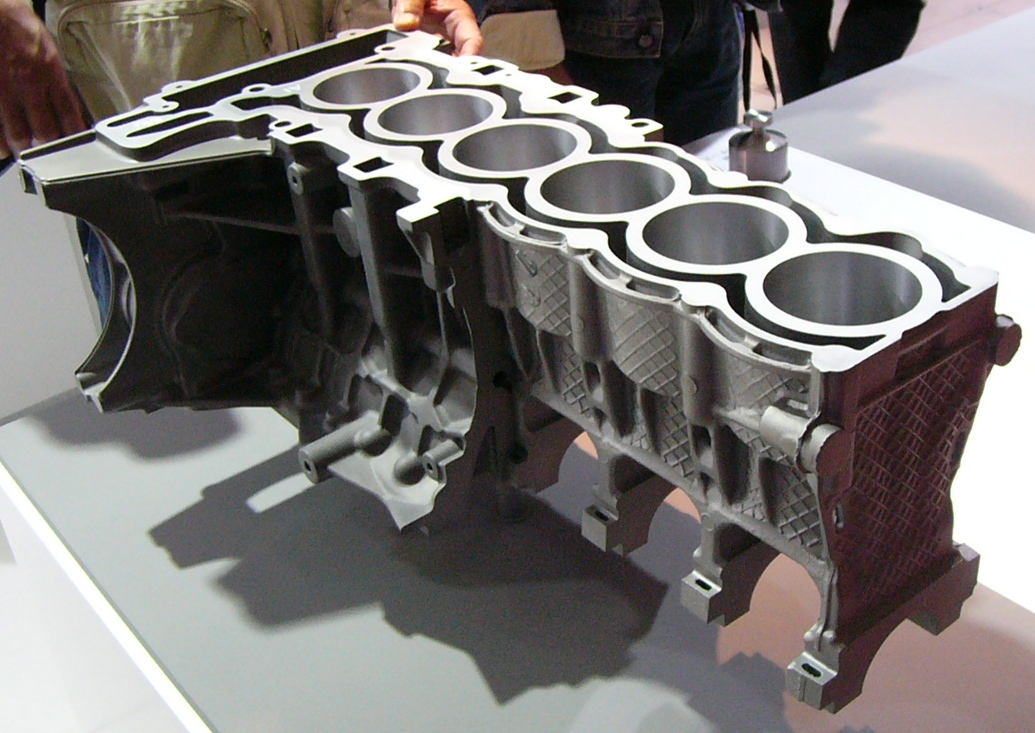

Core (manufacturing)

A core is a device used in casting and molding (process), moulding processes to produce internal cavities and wikt:reentrant, reentrant angles (an interior angle that is greater than 180°). The core is normally a disposable item that is destroyed to get it out of the piece.. They are most commonly used in sand casting, but are also used in die casting and injection moulding. For example, cores define multiple passages inside cast engine blocks. One model of GM V-8 engine requires 5 dry-sand cores for every casting. Materials required to make cores *Core sand *Bentonite clay *Pulverized coal *Resin oil Advantages and disadvantages Cores are useful for features that cannot tolerate draft (engineering), draft or to provide detail that cannot otherwise be integrated into a core-less casting or mold. The main disadvantage is the additional cost to incorporate cores. Requirements There are seven requirements for cores: #Green strength: In the green condition, there must be adequate s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stamping (metalworking)

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined. Stamping is usually ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die Casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high-volume production. Manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small- to medium-sized castings, which is why die casting produces more castings than any other casting process. Die castings are characterized by a very good surfac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inorganic Pigments

In chemistry, an inorganic compound is typically a chemical compound that lacks carbon–hydrogen bonds, that is, a compound that is not an organic compound. The study of inorganic compounds is a subfield of chemistry known as '' inorganic chemistry''. Inorganic compounds comprise most of the Earth's crust, although the compositions of the deep mantle remain active areas of investigation. Some simple carbon compounds are often considered inorganic. Examples include the allotropes of carbon (graphite, diamond, buckminsterfullerene, etc.), carbon monoxide, carbon dioxide, carbides, and the following salts of inorganic anions: carbonates, cyanides, cyanates, and thiocyanates. Many of these are normal parts of mostly organic systems, including organisms; describing a chemical as inorganic does not necessarily mean that it does not occur within living things. History Friedrich Wöhler's conversion of ammonium cyanate into urea in 1828 is often cited as the starting point of modern ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |