|

Double-acting Cylinder

In mechanical engineering, the cylinders of reciprocating engines are often classified by whether they are single- or double-acting, depending on how the working fluid acts on the piston. Single-acting A single-acting cylinder in a reciprocating engine is a cylinder in which the working fluid acts on one side of the piston only. A single-acting cylinder relies on the load, springs, other cylinders, or the momentum of a flywheel, to push the piston back in the other direction. Single-acting cylinders are found in most kinds of reciprocating engine. They are almost universal in internal combustion engines (e.g. petrol and diesel engines) and are also used in many external combustion engines such as Stirling engines and some steam engines. They are also found in pumps and hydraulic rams. Double-acting A double-acting cylinder is a cylinder in which the working fluid acts alternately on both sides of the piston. In order to connect the piston in a double-acting cylinder t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gland (engineering)

A stuffing box or gland package is an assembly which is used to house a gland seal. It is used to prevent leakage of fluid, such as water or steam, between sliding or turning parts of machine elements. Components A stuffing box of a sailing boat will have a stern tube that is slightly bigger than the prop shaft. It will also have packing nut threads or a gland nut. The packing is inside the gland nut and creates the seal. The shaft is wrapped by the packing and put in the gland nut. Through tightening it onto the stern tube, the packing is compressed, creating a seal against the shaft. , WindCheck Magazine, Retrieved April 27, 2016. Creating a proper plunger alignment is critical for correct flow and a long wear life. Stuffing box components are of stainless steel, brass or other application-specific ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Trunk Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder. __TOC__ Piston engines Internal combustion engines An internal combustion engine is acted upon by the pressure of the expanding combustion gases in the combustion chamber space at the top of the cylinder. This force then acts downwards through the connecting rod and onto the crankshaft. The connecting rod is attached ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crosshead

In mechanical engineering, a crosshead is a mechanical joint used as part of the slider-crank linkages of long reciprocating engines (either internal combustion or steam) and reciprocating compressors to eliminate sideways force on the piston. Also, the crosshead enables the connecting rod to freely move outside the cylinder. Because of the very small bore-to-stroke ratio on such engines, the connecting rod would hit the cylinder walls and block the engine from rotating if the piston was attached directly to the connecting rod like on trunk engines. Therefore, the longitudinal dimension of the crosshead must be matched to the stroke of the engine. Overview On smaller engines, the connecting rod links the piston and the crankshaft directly, but this transmits sideways forces to the piston, since the crankpin (and thus the direction the force is applied) moves from side to side with the rotary motion of the crank. These transverse forces are tolerable in a smaller engine. A la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

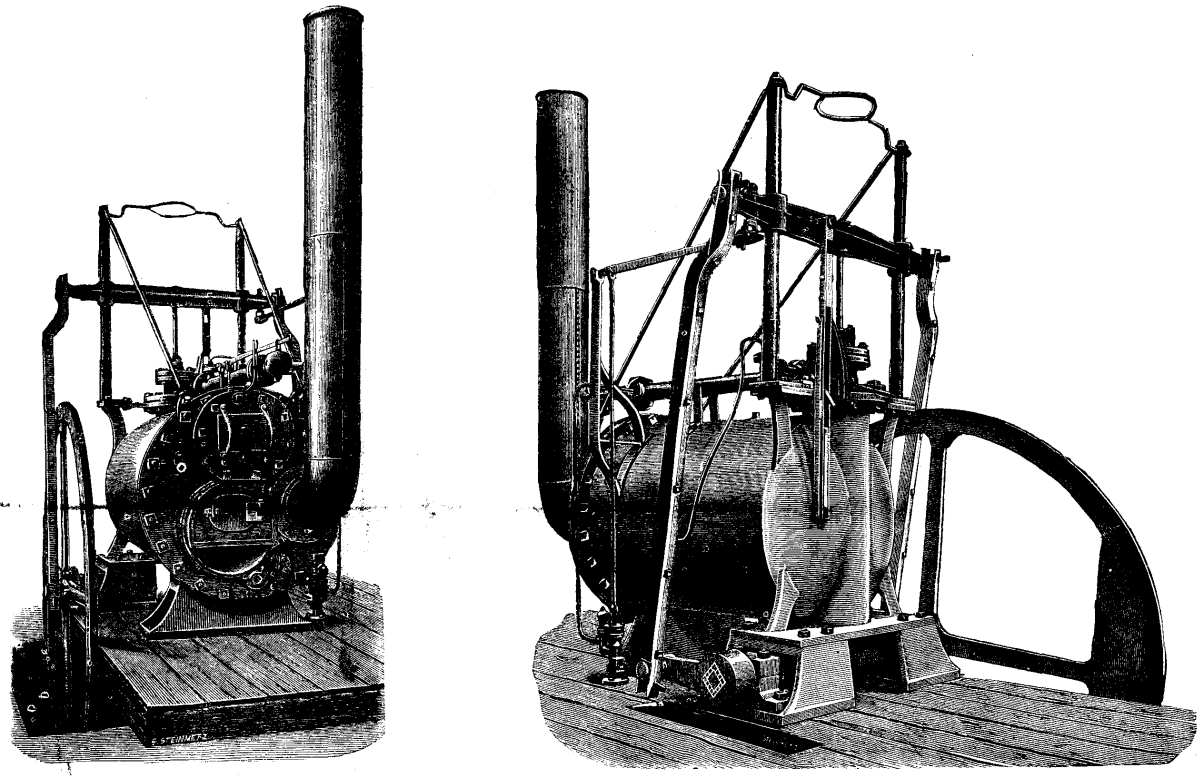

High-speed Steam Engine

High-speed steam engines were one of the final developments of the stationary steam engine. They ran at a high speed, of several hundred rpm,, 400 to 1,200 rpm which was needed by tasks such as electricity generation. Defining characteristics They have two primary characteristics: * High speed. : This is sufficient to drive a small dynamo directly, rather than needing a step-up drive by belts. * Accurate speed regulation. : Generation by dynamo requires a stable rotation speed for a stable output voltage, even when the load changes. When an alternator was being driven, the output frequency also depended upon a stable rotation speed. These also resulted in a number of secondary characteristics. Although these were not defining to the type, or were always the case, they were recognisably common: * Improved lubrication, as required by their high speed. : This often used an enclosed crankcase with an oil sump and lubrication by 'splash lubrication, splash' or by ring oilers. Som ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Richard Trevithick

Richard Trevithick (13 April 1771 – 22 April 1833) was a British inventor and mining engineer. The son of a mining captain, and born in the mining heartland of Cornwall, Trevithick was immersed in mining and engineering from an early age. He was an early pioneer of steam-powered road and rail transport, and his most significant contributions were the development of the first high-pressure steam engine and the first working railway steam locomotive. The world's first locomotive-hauled railway journey took place on 21 February 1804, when Trevithick's unnamed steam locomotive hauled a train along the tramway of the Penydarren Ironworks, in Merthyr Tydfil, Wales. Turning his interests abroad Trevithick also worked as a mining consultant in Peru and later explored parts of Costa Rica. Throughout his professional career he went through many ups and downs and at one point faced financial ruin, also suffering from the strong rivalry of many mining and steam engineers of the day. Du ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

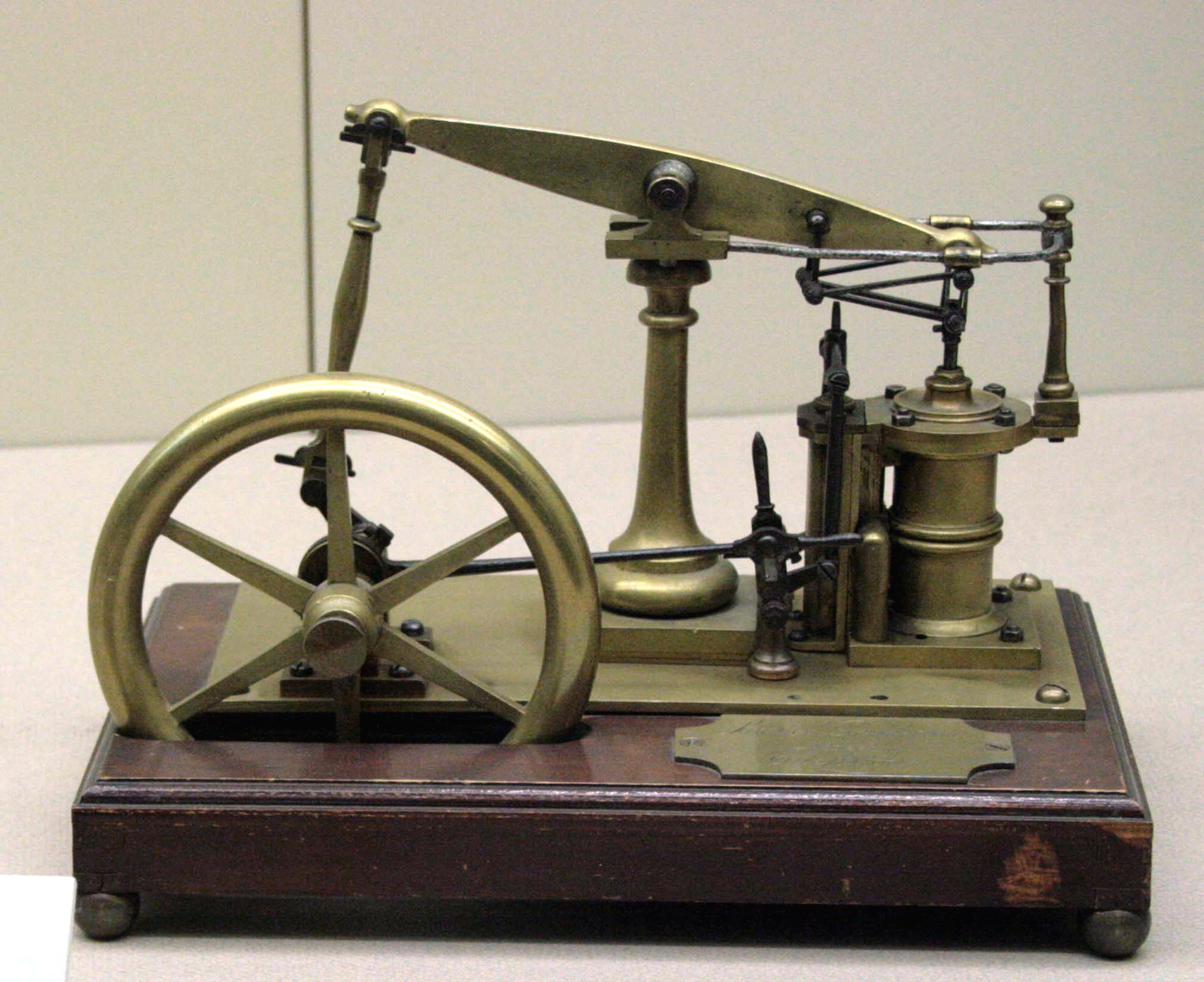

Rotative Beam Engine

A beam engine is a type of steam engine where a pivoted overhead beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newcomen around 1705 to remove water from mines in Cornwall. The efficiency of the engines was improved by engineers including James Watt, who added a separate condenser; Jonathan Hornblower and Arthur Woolf, who compounded the cylinders; and William McNaught, who devised a method of compounding an existing engine. Beam engines were first used to pump water out of mines or into canals but could be used to pump water to supplement the flow for a waterwheel powering a mill. The rotative beam engine is a later design of beam engine where the connecting rod drives a flywheel by means of a crank (or, historically, by means of a sun and planet gear). These beam engines could be used to directly power the line-shafting in a mill. They als ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

James Watt

James Watt (; 30 January 1736 (19 January 1736 OS) – 25 August 1819) was a Scottish inventor, mechanical engineer, and chemist who improved on Thomas Newcomen's 1712 Newcomen steam engine with his Watt steam engine in 1776, which was fundamental to the changes brought by the Industrial Revolution in both his native Great Britain and the rest of the world. While working as an instrument maker at the University of Glasgow, Watt became interested in the technology of steam engines. He realised that contemporary engine designs wasted a great deal of energy by repeatedly cooling and reheating the cylinder. Watt introduced a design enhancement, the separate condenser, which avoided this waste of energy and radically improved the power, efficiency, and cost-effectiveness of steam engines. Eventually, he adapted his engine to produce rotary motion, greatly broadening its use beyond pumping water. Watt attempted to commercialise his invention, but experienced great financial ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Beam (beam Engine)

Beam may refer to: Streams of particles or energy *Light beam, or beam of light, a directional projection of light energy **Laser beam *Particle beam, a stream of charged or neutral particles **Charged particle beam, a spatially localized group of electrically charged particles ***Cathode ray, or electron beam or e-beam, streams of electrons observed in discharge tubes ***X-ray beam, a penetrating form of high-energy electromagnetic radiation **Molecular beam, a beam of particles moving at approximately equal velocities Arts, entertainment and media * Anong Beam, Canadian Ojibwe artist and curator * Beam (music), a connection line in musical notation * Beam, to transport matter using the Transporter in the ''Star Trek'' fictional universe * Beam (rapper), American hip hop artist * BEAM.TV, an online digital delivery and content management platform * BEAM Channel 31, a Philippines television network * Beam (website), later Mixer, a former video game live streaming platfor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Beam Engine

A beam engine is a type of steam engine where a pivoted overhead beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newcomen around 1705 to remove water from mines in Cornwall. The efficiency of the engines was improved by engineers including James Watt, who added a separate condenser; Jonathan Hornblower and Arthur Woolf, who compounded the cylinders; and William McNaught, who devised a method of compounding an existing engine. Beam engines were first used to pump water out of mines or into canals but could be used to pump water to supplement the flow for a waterwheel powering a mill. The rotative beam engine is a later design of beam engine where the connecting rod drives a flywheel by means of a crank (or, historically, by means of a sun and planet gear). These beam engines could be used to directly power the line-shafting in a mill. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Atmospheric Engine

The atmospheric engine was invented by Thomas Newcomen in 1712, and is often referred to as the Newcomen fire engine (see below) or simply as a Newcomen engine. The engine was operated by condensing steam drawn into the cylinder, thereby creating a partial vacuum which allowed the atmospheric pressure to push the piston into the cylinder. It was historically significant as the first practical device to harness steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines. Hundreds were constructed throughout the 18th century. James Watt's later engine design was an improved version of the Newcomen engine that roughly doubled fuel efficiency. Many atmospheric engines were converted to the Watt design, for a price which was based on a fraction of the fuel-savings. As a result, Watt is today better known than Newcomen in relation to the origin of the steam engine. Precursors Prior to Newcomen a number of small ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and crank, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term ''steam engine'' can refer to either complete steam plants (including boilers etc.), such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine. Although steam-driven devices were known as early as the aeoli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |