|

Dexel

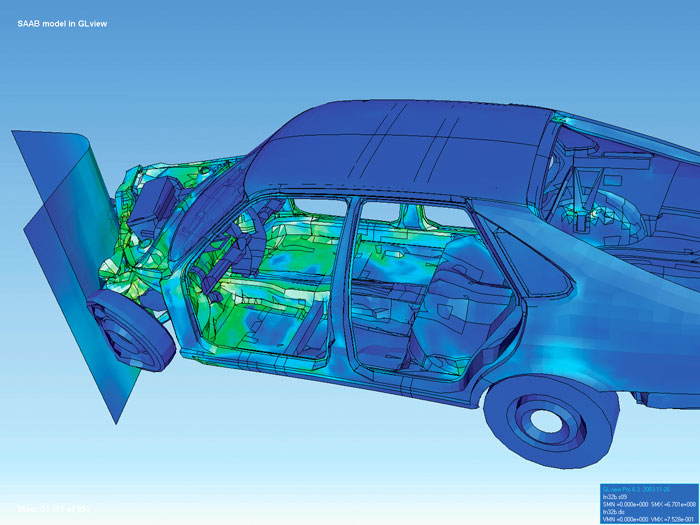

The term ''Dexel'' has two common uses: Dexel ("depth pixel") is a concept used for a discretized representation of functions defined on surfaces used in geometrical modeling and physical simulation, sometimes also referred to as multilevel Z-map. Dexel is a nodal value of a Scalar (mathematics), scalar or vector field on a meshed surface. Dexels are used in simulation of manufacturing processes (such as turning, Milling machine, milling or rapid prototyping), when workpiece surfaces are subject to modifications. It is practical to express the surface evolution by dexels especially when the surface evolution scale is very different from the structural finite element 3D model discretization step (e.g. in machining the depth of cut variation is often several orders of magnitude smaller (1–10 µm) than the FE model mesh step (1 mm)). Dexel ("detector element") is the analog of a pixel ("picture element") but native to a detector rather than a visible picture. That is, it d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pixel

In digital imaging, a pixel (abbreviated px), pel, or picture element is the smallest addressable element in a raster image, or the smallest point in an all points addressable display device. In most digital display devices, pixels are the smallest element that can be manipulated through software. Each pixel is a sample of an original image; more samples typically provide more accurate representations of the original. The intensity of each pixel is variable. In color imaging systems, a color is typically represented by three or four component intensities such as red, green, and blue, or cyan, magenta, yellow, and black. In some contexts (such as descriptions of camera sensors), ''pixel'' refers to a single scalar element of a multi-component representation (called a ''photosite'' in the camera sensor context, although ''sensel'' is sometimes used), while in yet other contexts (like MRI) it may refer to a set of component intensities for a spatial position. Etymology The w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scalar (mathematics)

A scalar is an element of a field which is used to define a ''vector space''. In linear algebra, real numbers or generally elements of a field are called scalars and relate to vectors in an associated vector space through the operation of scalar multiplication (defined in the vector space), in which a vector can be multiplied by a scalar in the defined way to produce another vector. Generally speaking, a vector space may be defined by using any field instead of real numbers (such as complex numbers). Then scalars of that vector space will be elements of the associated field (such as complex numbers). A scalar product operation – not to be confused with scalar multiplication – may be defined on a vector space, allowing two vectors to be multiplied in the defined way to produce a scalar. A vector space equipped with a scalar product is called an inner product space. A quantity described by multiple scalars, such as having both direction and magnitude, is called a '' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Simulation

A simulation is the imitation of the operation of a real-world process or system over time. Simulations require the use of Conceptual model, models; the model represents the key characteristics or behaviors of the selected system or process, whereas the simulation represents the evolution of the model over time. Often, computers are used to execute the computer simulation, simulation. Simulation is used in many contexts, such as simulation of technology for performance tuning or optimizing, safety engineering, testing, training, education, and video games. Simulation is also used with scientific modelling of natural systems or human systems to gain insight into their functioning, as in economics. Simulation can be used to show the eventual real effects of alternative conditions and courses of action. Simulation is also used when the real system cannot be engaged, because it may not be accessible, or it may be dangerous or unacceptable to engage, or it is being designed bu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed into a final p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turning

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates. Usually the term "turning" is reserved for the generation of ''external'' surfaces by this cutting action, whereas this same essential cutting action when applied to ''internal'' surfaces (holes, of one kind or another) is called " boring". Thus the phrase "turning and boring" categorizes the larger family of processes known as lathing. The cutting of faces on the workpiece, whether with a turning or boring tool, is called "facing", and may be lumped into either category as a subset. Turning can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using an automated lathe which does not. Today the most common type of such automation is computer numerical control, better known as CNC. (CNC is also commonly used with many other typ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rapid Prototyping

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data. Construction of the part or assembly is usually done using 3D printing or "additive layer manufacturing" technology. The first methods for rapid prototyping became available in the mid 1987 and were used to produce models and prototype parts. Today, they are used for a wide range of applications and are used to manufacture production-quality parts in relatively small numbers if desired without the typical unfavorable short-run economics. This economy has encouraged online service bureaus. Historical surveys of RP technology start with discussions of simulacra production techniques used by 19th-century sculptors. Some modern sculptors use the progeny technology to produce exhibitions and various objects. The ability to reproduce designs from a dataset has given rise to issues of rights, as it is now possibl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finite Element

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The FEM is a general numerical method for solving partial differential equations in two or three space variables (i.e., some boundary value problems). To solve a problem, the FEM subdivides a large system into smaller, simpler parts that are called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numerical domain for the solution, which has a finite number of points. The finite element method formulation of a boundary value problem finally results in a system of algebraic equations. The method approximates the unknown function over the domain. The simple ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Engineering

Mechanical engineering is the study of physical machines that may involve force and movement. It is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the engineering branches. Mechanical engineering requires an understanding of core areas including mechanics, dynamics, thermodynamics, materials science, structural analysis, and electricity. In addition to these core principles, mechanical engineers use tools such as computer-aided design (CAD), computer-aided manufacturing (CAM), and product lifecycle management to design and analyze manufacturing plants, industrial equipment and machinery, heating and cooling systems, transport systems, aircraft, watercraft, robotics, medical devices, weapons, and others. Mechanical engineering emerged as a field during the Industrial Revolution in Europe in the 18th century; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |