|

Deep Drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius. Deep drawing presses, especially in the Aerospace and Medical industries, require unparalleled accuracy and precision. Sheet hydroforming presses do complex draw work. Bed size, tonnage, stroke, speed, and more ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

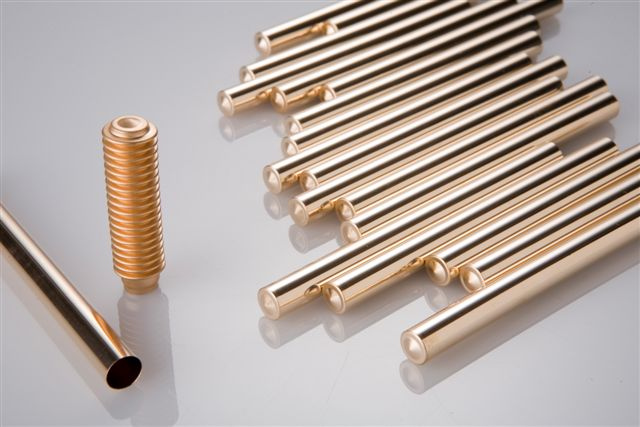

Parts Made By Deep Drawing - 20100630

Part, parts or PART may refer to: People *Armi Pärt (born 1991), Estonian handballer *Arvo Pärt (born 1935), Estonian classical composer *Brian Part (born 1962), American child actor *Dealtry Charles Part (1882–1961), sheriff (1926–1927) and Lord Lieutenant (1943–1957) of Bedfordshire, racehorse owner *Dionysius Part (also known as ''Denys Part''; died 1475), Roman Catholic prelate, Auxiliary Bishop of Mainz (1474–1475) *John Part (born 1966), Canadian darts player *Michael Pärt (born 1977), Estonian music producer and film composer *Veronika Part (born 1978), Russian ballet dancer *Pärt Uusberg (born 1986), Estonian composer and conductor * Parts (surname) Arts, entertainment, and media *Part (music), a single strand or melody or harmony of music within a larger ensemble or a polyphonic musical composition * ''Parts'' (book), a 1997 children's book by Tedd Arnold Transportation * Pottstown Area Rapid Transit (PART), Pennsylvania, U.S. *Putnam Area Rapid Transit (PART ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous ( iron-based) metals and nonferrous metals such as aluminum or copper. Cop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Forming

Forming, metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged. Forming operates on the materials science principle of plastic deformation, where the physical shape of a material is permanently deformed. Characteristics Metal forming tends to have more uniform characteristics across its subprocesses than its contemporary processes, cutting and joining. On the industrial scale, forming is characterized by: * Very high loads and stresses required, between 50 and () * Large, heavy, and expensive machinery in order to accommodate such high stresses and loads * Production runs with many parts, to maximize the economy of production and compensate for the expense of the machine tools Forming processes Forming processes tend to be categorised by differences in effective stresses. These categories and descriptions are highly simplifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Stress

In mechanics, a cylinder stress is a stress distribution with rotational symmetry; that is, which remains unchanged if the stressed object is rotated about some fixed axis. Cylinder stress patterns include: * circumferential stress, or hoop stress, a normal stress in the tangential (azimuth) direction. * axial stress, a normal stress parallel to the axis of cylindrical symmetry. * radial stress, a normal stress in directions coplanar with but perpendicular to the symmetry axis. These three principal stresses- hoop, longitudinal, and radial can be calculated analytically using a mutually perpendicular tri-axial stress system. The classical example (and namesake) of hoop stress is the tension applied to the iron bands, or hoops, of a wooden barrel. In a straight, closed pipe, any force applied to the cylindrical pipe wall by a pressure differential will ultimately give rise to hoop stresses. Similarly, if this pipe has flat end caps, any force applied to them by static pressure w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plane Strain

In continuum mechanics, the infinitesimal strain theory is a mathematical approach to the description of the deformation of a solid body in which the displacements of the material particles are assumed to be much smaller (indeed, infinitesimally smaller) than any relevant dimension of the body; so that its geometry and the constitutive properties of the material (such as density and stiffness) at each point of space can be assumed to be unchanged by the deformation. With this assumption, the equations of continuum mechanics are considerably simplified. This approach may also be called small deformation theory, small displacement theory, or small displacement-gradient theory. It is contrasted with the finite strain theory where the opposite assumption is made. The infinitesimal strain theory is commonly adopted in civil and mechanical engineering for the stress analysis of structures built from relatively stiff elastic materials like concrete and steel, since a common goal in t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Formability

Formability is the ability of a given metal workpiece to undergo plastic deformation without being damaged. The plastic deformation capacity of metallic materials, however, is limited to a certain extent, at which point, the material could experience tearing or fracture (breakage). Processes affected by the formability of a material include: rolling, extrusion, forging, rollforming, stamping, and hydroforming. Fracture strain A general parameter that indicates the formability and ductility of a material is the fracture strain which is determined by a uniaxial tensile test (see also fracture toughness). The strain identified by this test is defined by elongation with respect to a reference length. For example, a length of is used for the standardized uniaxial test of flat specimens, pursuant to EN 10002. It is important to note that deformation is homogeneous up to uniform elongation. Strain subsequently localizes until fracture occurs. Fracture strain is not an engineering st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deep Draw Line Example By Pressteck Italy

Deep or The Deep may refer to: Places United States * Deep Creek (Appomattox River tributary), Virginia * Deep Creek (Great Salt Lake), Idaho and Utah * Deep Creek (Mahantango Creek tributary), Pennsylvania * Deep Creek (Mojave River tributary), California * Deep Creek (Pine Creek tributary), Pennsylvania * Deep Creek (Soque River tributary), Georgia * Deep Creek (Texas), a tributary of the Colorado River * Deep Creek (Washington), a tributary of the Spokane River * Deep River (Indiana), a tributary of the Little Calumet River * Deep River (Iowa), a minor tributary of the English River * Deep River (North Carolina) * Deep River (Washington), a minor tributary of the Columbia River * Deep Voll Brook, New Jersey, also known as Deep Brook Elsewhere * Deep Creek (Bahamas) * Deep Creek (Melbourne, Victoria), Australia, a tributary of the Maribyrnong River * Deep River (Western Australia) People * Deep (given name) * Deep (rapper), Punjabi rapper from Houston, Texas * Ravi Deep (b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool Steel

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures. As a result, tool steels are suited for use in the shaping of other materials, as for example in cutting, machining, stamping, or forging. With a carbon content between 0.5% and 1.5%, tool steels are manufactured under carefully controlled conditions to produce the required quality. The presence of carbides in their matrix plays the dominant role in the qualities of tool steel. The four major alloying elements that form carbides in tool steel are: tungsten, chromium, vanadium and molybdenum. The rate of dissolution of the different carbides into the austenite form of the iron determines the high-temperature performance of st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states: * no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect; * the specified minimum for copper does not exceed 0.40%; * or the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65%; silicon 0.60%; copper 0.60%. The term ''carbon steel'' may also be used in reference to steel which is not stainless steel; in this use carbon steel may include alloy steels. High carbon steel has many different uses such as milling machines, cutting tools (such as chisels) and high strength wires. These applications require a much finer microstructure, which improves the toughness. Carbon steel is a popular metal choic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloy Steel

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties. Alloy steels are broken down into two groups: low alloy steels and high alloy steels. The difference between the two is disputed. Smith and Hashemi define the difference at 4.0%, while Degarmo, ''et al.'', define it at 8.0%.Degarmo, p. 112. Most commonly, the phrase "alloy steel" refers to low-alloy steels. Strictly speaking, every steel is an alloy, but not all steels are called "alloy steels". The simplest steels are iron (Fe) alloyed with carbon (C) (about 0.1% to 1%, depending on type) and nothing else (excepting negligible traces via slight impurities); these are called carbon steels. However, the term "alloy steel" is the standard term referring to steels with ''other'' alloying elements added deliberately ''in addition to'' the carbon. Common alloyants include manganese (the most common one), nickel, chromium, molybdenum, van ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

White Lead

White lead is the basic lead carbonate 2PbCO3·Pb(OH)2. It is a complex salt, containing both carbonate and hydroxide ions. White lead occurs naturally as a mineral, in which context it is known as hydrocerussite, a hydrate of cerussite. It was formerly used as an ingredient for lead paint and a cosmetic called Venetian ceruse, because of its opacity and the satiny smooth mixture it made with dryable oils. However, it tended to cause lead poisoning, and its use has been banned in most countries. White lead compounds known as lead soap were also used as additive for lubricants for bearings and in machine shops. Lead soap was also used as an oil drying agent for paints made with drying oil or air drying paints made with alkyd resins. Lead is often used with cobalt driers. Lead free substitutes have been developed to replace this use of lead in paint. History What is commonly known today as the "Dutch method" for the preparation of white lead was described as early as Theoph ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Circle Grid Analysis

Circle grid analysis (CGA), also known as circle grid strain analysis, is a method of measuring the strain levels of sheet metal after a part is formed by stamping or drawing. The name itself is a fairly accurate description of the process. Literally, a grid of circles of known diameter is etched to the surface of the sheet metal to be formed. After the part is formed, the circles have been stretched into ellipses. By measuring the longest part of the ellipse (called the “major strain”) and the shortest part of the ellipse (called the “minor strain”), it is possible to determine how close any stamped part is to splitting or fracturing. The goal of using circle grid strain analysis is to predict potential problems before they become problems. Once you have a forming problem, chances are circle grid analysis won’t be able to help you, unless it’s intermittent enough to form a “good” part from time to time. See also *Forming limit diagram A forming limit diagram, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |