|

Drag Link

A drag link converts rotary motion from a crank arm, to a second bellcrank, usually in an automotive steering system. While the origin of the term is not clear, it pre-dates the automobile, and is described as in use in 1849 as a means of rotating a Ducie cultivator being operated by cable by stationary steam engine (or between engines). Automotive use The term is commonly used in automotive technology for the link in steering linkage that connects the drop arm (also called pitman arm) on the steering box to a ''steering arm'' which causes the wheels to steer the vehicle. Normally the drop link connects to one wheel which is connected to the other wheel by a track rod (or tie rod) which is an adjustable rod which determines the relative wheel alignment. Typically, one end of the drag link is connected via the drop arm (also called Pitman arm) and steering gearbox to the steering wheel (providing the connection between the driver and the steering system); the other end is attache ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

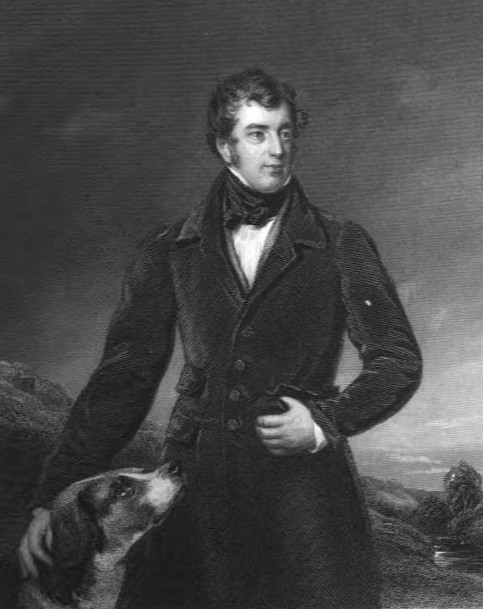

Henry Reynolds-Moreton, 2nd Earl Of Ducie

Henry George Francis Reynolds-Moreton, 2nd Earl of Ducie (8 May 1802 – 2 June 1853), styled the Hon. Henry Reynolds-Moreton from 1808 to 1837 and the Lord Moreton from 1837 to 1840, was a British Whig politician, agriculturalist and cattle breeder. Early life Ducie was born on 8 May 1802, the son of Thomas Reynolds-Moreton, 1st Earl of Ducie, and his wife Lady Frances Herbert, daughter of Henry Herbert, 1st Earl of Carnarvon. He was educated at Eton. Lord Ducie married the Hon. Elizabeth, daughter of John Dutton, 2nd Baron Sherborne, on 29 June 1826. They had eleven sons and four daughters. Career Lord Moreton entered Parliament for Gloucestershire in 1831, a seat he held until the following year when the constituency was abolished, and then represented Gloucestershire East until 1835. After entering the House of Lords on the death of his father in 1840 he served in the Whig administration of Lord Russell as a Lord-in-waiting (government whip in the House of Lords) from 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automotive Technology

Automotive engineering, along with aerospace engineering and naval architecture, is a branch of vehicle engineering, incorporating elements of mechanical, electrical, electronic, software, and safety engineering as applied to the design, manufacture and operation of motorcycles, automobiles, and trucks and their respective engineering subsystems. It also includes modification of vehicles. Manufacturing domain deals with the creation and assembling the whole parts of automobiles is also included in it. The automotive engineering field is research intensive and involves direct application of mathematical models and formulas. The study of automotive engineering is to design, develop, fabricate, and test vehicles or vehicle components from the concept stage to production stage. Production, development, and manufacturing are the three major functions in this field. Disciplines Automobile engineering Automobile engineering is a branch study of engineering which teaches manufacturing, de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pitman Arm

A Pitman arm is a shaft that translates rotary or angular movement into linear movement, or vice versa. Pitman arms are commonly found in water pumping windmills, automotive steering systems, and sewing machines. In windmills, the Pitman arm connects the driving gear to the pumping arm. It translates the rotary power from the wind blades to the up-and-down motion of the pumping arm. In automotive or truck steering systems, the Pitman arm acts as a linkage attached to the steering box (see recirculating ball) sector shaft, it converts the angular motion of the sector shaft into the linear motion needed to steer the wheels. The arm is supported by the sector shaft and supports the drag link or center link with a ball joint. It transmits the motion it receives from the steering box into the drag (or center) link, causing it to move left or right to turn the wheels in the appropriate direction. The idler arm is attached between the opposite side of the center link from the Pitman ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tie Rod

A tie rod or tie bar (also known as a hanger rod if vertical) is a slender structural unit used as a tie and (in most applications) capable of carrying tensile loads only. It is any rod or bar-shaped structural member designed to prevent the separation of two parts, as in a vehicle. Subtypes and examples of applications * In airplane structures, tie rods are sometimes used in the fuselage or wings. * Tie rods are often used in steel structures, such as bridges, industrial buildings, tanks, towers, and cranes. * Sometimes tie rods are retrofitted to bowing or subsiding masonry walls (brick, block, stone, etc.) to keep them from succumbing to lateral forces. * The rebar used in reinforced concrete is not referred to as a "tie rod", but it essentially performs some of the same tension-force-counteracting purposes that tie rods perform. * In automobiles, the ''tie rods'' are part of the steering mechanism. They differ from the archetypal tie rod by both pushing and pulling (operatin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pitman Arm

A Pitman arm is a shaft that translates rotary or angular movement into linear movement, or vice versa. Pitman arms are commonly found in water pumping windmills, automotive steering systems, and sewing machines. In windmills, the Pitman arm connects the driving gear to the pumping arm. It translates the rotary power from the wind blades to the up-and-down motion of the pumping arm. In automotive or truck steering systems, the Pitman arm acts as a linkage attached to the steering box (see recirculating ball) sector shaft, it converts the angular motion of the sector shaft into the linear motion needed to steer the wheels. The arm is supported by the sector shaft and supports the drag link or center link with a ball joint. It transmits the motion it receives from the steering box into the drag (or center) link, causing it to move left or right to turn the wheels in the appropriate direction. The idler arm is attached between the opposite side of the center link from the Pitman ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rack And Pinion

A rack and pinion is a type of linear actuator that comprises a circular gear (the '' pinion'') engaging a linear gear (the ''rack''). Together, they convert rotational motion into linear motion. Rotating the pinion causes the rack to be driven in a line. Conversely, moving the rack linearly will cause the pinion to rotate. A rack and pinion drive can use both straight and helical gears. Though some suggest helical gears are quieter in operation, no hard evidence supports this theory. Helical racks, while being more affordable, have proven to increase side torque on the datums, increasing operating temperature leading to premature wear. Straight racks require a lower driving force and offer increased torque and speed per percentage of gear ratio which allows lower operating temperature and lessens viscal friction and energy use. The maximum force that can be transmitted in a rack and pinion mechanism is determined by the tooth pitch and the size of the pinion as well as the gear ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |