|

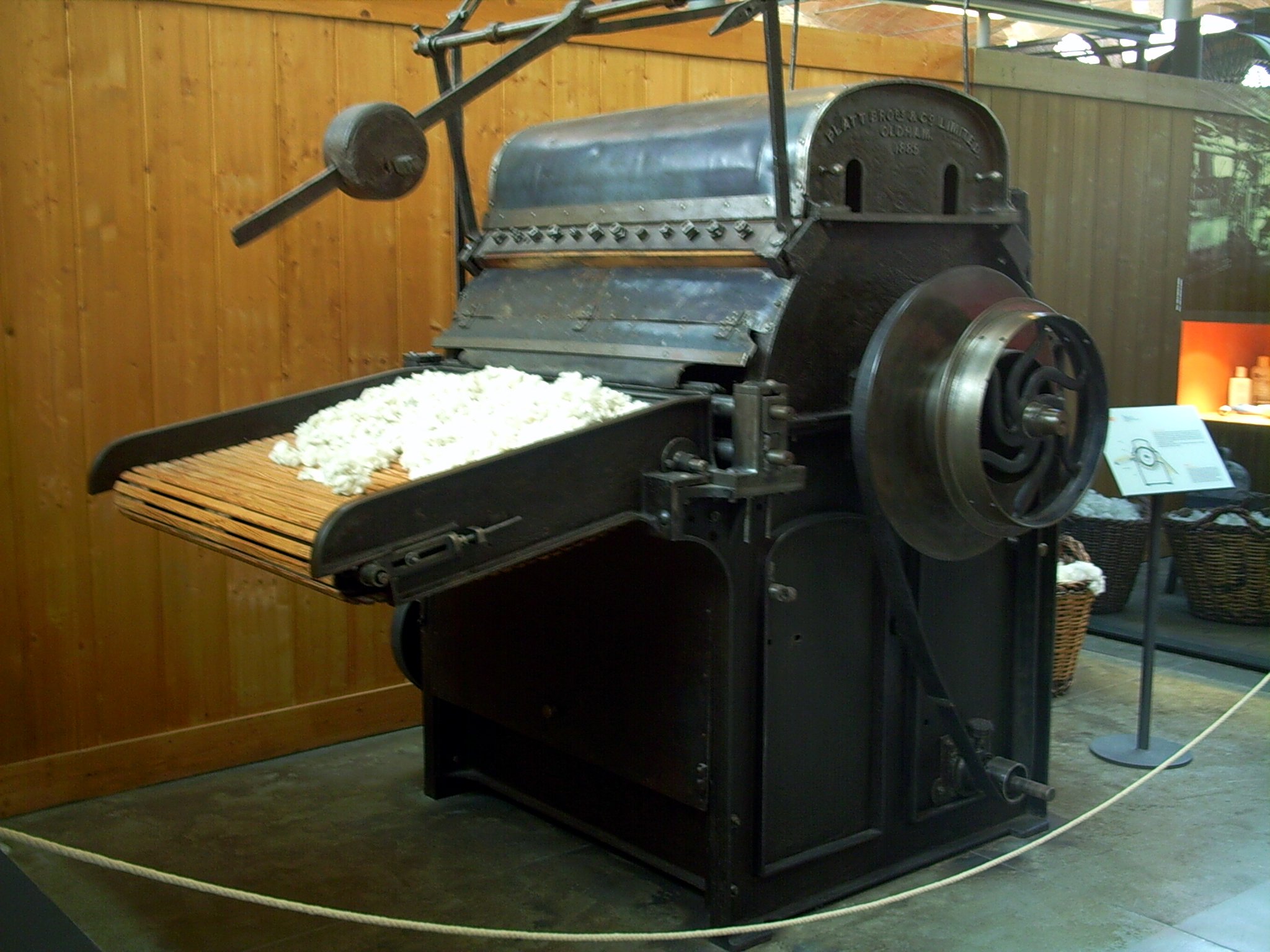

Doffing Cylinder

A doffing cylinder, also called doffing roller or commonly just doffer is a component used in textile mills to remove fiber from the main cylinder of a card, on which the fibers have been straightened and aligned. The main cylinder of the card will have one or two doffers that comb and remove the fiber. The doffer is set with pins that hold the fiber, which is then removed by a comb or knife and fed into the next stage of production. Doffers are also used in cotton pickers and other machinery that handle fiber. Confusingly, the word doffer (meaning something that takes off, as in "doff your hat") is also used for mill workers whose job it is to remove full bobbins or pirns holding spun fiber and replace them with empty bobbins or pirns. In modern mills, a machine called a doffer may do this task. Early years Some people have given credit to Richard Arkwright for inventing the doffer, which was incorporated in his machine, but others consider that it was invented by James Hargrea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Masson Mills WTM 19 Breaker Cards 5943

*

{{disambiguation, geo ...

Masson may refer to: Places * Masson (electoral district), a Quebec provincial electoral district * Masson Island, an Antarctic island * Masson Range, a mountain range in Antarctica Other uses * Masson (surname) * Masson (publisher), a French publisher of scientific books * Masson Hall, the first "proper" hall of residence for women attending the University of Edinburgh, now closed See also * Paul Masson Mountain Winery * Masson-Angers, Quebec, a sector of the city of Gatineau, Quebec, Canada * Macon (other) * Mason (other) * Marson (other) Marson is a commune in the canton of Châlons-en-Champagne-3, Marne, Grand Est, France Marson may also refer to: * Marson (surname) * , a commune in the Meuse, Grand Est, France * Rou-Marson a commune in the Loire Valley, France See also * * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Textile Mill

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Different types of fibres are used to produce yarn. Cotton remains the most widely used and common natural fiber making up 90% of all-natural fibers used in the textile industry. People often use cotton clothing and accessories because of comfort, not limited to different weathers. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide range of products. History Textile manufacturing in the modern era is an evolved form of the art and craft industries. Until the 18th and 19th centuries, the textile industry was a household work. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carding

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver (textiles), sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with "card clothing", a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing. The word is derived from the Latin meaning thistle or Dipsacus, teasel, as dried vegetable teasels were first used to comb the raw wool before technological advances led to the use of machines. Overview These ordered fibres can then be passed on to other processes that are specific to the desired end use of the fibre: Cotton mill, Cotton, Batting (material), batting, felt, woollen or worsted yarn, etc. Carding can also be used to create blends of dif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cotton Picker

A cotton picker is either a machine that harvests cotton, or a person who picks ripe cotton fibre from the plants. The machine is also referred to as a cotton harvester. History In many societies, like America, slave and serf labor was utilized to pick the cotton, increasing the plantation owner's profit margins (See Trans-Atlantic Slave Trade). The first practical cotton picker was invented over a period of years beginning in the late 1920s by John Daniel Rust (1892–1954) with the later help of his brother Mack Rust. Other inventors had tried designs with a barbed spindle to twist cotton fibers onto the spindle and then pull the cotton from the boll, but these early designs were impractical because the spindle became clogged with cotton. Rust determined that a smooth, moist spindle could be used to strip the fibers from the boll without trapping them in the machinery. In 1933 John Rust received his first patent, and eventually, he and his brother owned forty-seven patents o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Doffer

A doffer is someone who removes ("doffs") bobbins, pirns or spindles holding spun fiber such as cotton or wool from a spinning frame and replaces them with empty ones. Historically, spinners, doffers, and sweepers each had separate tasks that were required in the manufacture of spun textiles. From the early days of the industrial revolution, this work, which requires speed and dexterity rather than strength, was often done by children. After World War I, the practice of employing children declined, ending in the United States in 1933. In modern textile mills, doffing machines have now replaced humans. The 19th century The Industrial Revolution created growing demand for child labor in the mills and factories, since children were easier to supervise than adults and good at monotonous, repetitive tasks that often required little physical strength, but where small bodies and nimble fingers were an advantage. Children were employed in the mills as spinners, sweepers and doffers, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bobbin

A bobbin or spool is a spindle or cylinder, with or without flanges, on which yarn, thread, wire, tape or film is wound. Bobbins are typically found in industrial textile machinery, as well as in sewing machines, fishing reels, tape measures, film rolls, cassette tapes, within electronic and electrical equipment, and for various other applications. Industrial textiles Bobbins are used in spinning, weaving, knitting, sewing, and lacemaking. In these practices, bobbins were invented to "manage the piles of thread and yarn that would be mechanically woven into cloth," where the mechanical began using human power, but eventual became machine-driven. In these applications, bobbins provide storage, temporary and permanent, for yarn or thread. Historically, bobbins were made out of natural materials such as wood, or bone. While not in principle an invention of the Victorian era—bobbins in the production of textiles were in earlier use—the machinery introduced in that e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pirn

A Pirn is a rod onto which weft thread is wound for use in weaving. Unlike a bobbin, it is fixed in place, and the thread is delivered off the end of the pirn rather than from the centre. A typical pirn is made of wood or plastic and is slightly tapered for most of its length, flaring out more sharply at the base, which fits over a pin in the shuttle. Pirns are wound from the base forward in order to ensure snag-free delivery of the thread, unlike bobbins, which are wound evenly from end to end. Pirns became important with the development of the flying shuttle The flying shuttle was one of the key developments in the industrialization of weaving during the early Industrial Revolution. It allowed a single weaver to weave much wider fabrics, and it could be mechanized, allowing for automatic machine l ..., though they are also used with other end delivery shuttles. Power looms which use pirns generally have automatic changing mechanisms which remove the spent pirn from the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Richard Arkwright

Sir Richard Arkwright (23 December 1732 – 3 August 1792) was an English inventor and a leading entrepreneur during the early Industrial Revolution. He is credited as the driving force behind the development of the spinning frame, known as the water frame after it was adapted to use water power; and he patented a rotary carding engine to convert raw cotton to 'cotton lap' prior to spinning. He was the first to develop factories housing both mechanised carding and spinning operations. Arkwright's achievement was to combine power, machinery, semi-skilled labour and the new raw material of cotton to create mass-produced yarn. His organisational skills earned him the accolade "father of the modern industrial factory system," notably through the methods developed in his mill at Cromford, Derbyshire (now preserved as part of the Derwent Valley Mills World Heritage Site). Life and family Richard Arkwright was born in Preston, Lancashire, England on 23 December 1732, the youngest ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

James Hargreaves

James Hargreaves ( 1720 – 22 April 1778) was an English weaver, carpenter and inventor who lived and worked in Lancashire, England. He was one of three men responsible for the mechanisation of spinning: Hargreaves is credited with inventing the spinning jenny in 1764; Richard Arkwright patented the water frame in 1769; and Samuel Crompton combined the two, creating the spinning mule in 1779. Life and work James Hargreaves was born at Stanhill, Oswaldtwistle in Lancashire. He was described as "stout, broadest man of about five-foot ten, or rather more". He was illiterate and worked as a hand loom weaver during most of his life. He married and baptismal records show he had 13 children, of whom the author Baines in 1835 was aware of '6 or 7'. Spinning jenny The idea for the spinning jenny is said to have come when a one-thread spinning wheel was overturned on the floor, and Hargreaves saw both the wheel and the spindle continuing to revolve. He realized that if several s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Samuel Crompton

Samuel Crompton (3 December 1753 – 26 June 1827) was an English inventor and pioneer of the spinning industry. Building on the work of James Hargreaves and Richard Arkwright he invented the spinning mule, a machine that revolutionised the industry worldwide. Early life Samuel Crompton was born in 10 Firwood Fold, Bolton, Lancashire to George and Betty Crompton (née Elizabeth Holt of Turton). His father was a caretaker at nearby Hall i' th' Wood. Samuel had two younger sisters. While he was a boy he lost his father and had to contribute to the family resources by spinning yarn, learning to spin on James Hargreaves's spinning jenny. The deficiencies of the Jenny imbued him with the idea of devising something better, which he worked on in secret for five or six years. The effort absorbed all his spare time and money, including that which he earned by playing the violin at the Bolton theatre. On 16 February 1780 at Bolton Parish Church, Crompton married Mary Pimlott (or P ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

-06.jpg)

_and_her_daughter_Mary_Anne%2C_by_Joseph_Wright_of_Derby.jpg)