|

Cooper Ring

A Wills Ring or Cooper Ring is a form of all-metallic O-ring seal. They are used for extremely arduous service, such as sealing the head gasket of high performance piston engines. Hollow, metallic Wills Rings are used as they have better springback than yielding soft metal seals and higher temperature limits than elastomer O rings. Construction A Wills Ring is an O-ring in the form of a hollow metallic tube. They are pressurised internally by gas pressure The advantages of this construction are that the rings can seal against a wide range of conditions. Metallic construction makes them robust against high or low temperatures and chemical attack. Softer coatings may be applied to provide even better compatibility, or to seal against roughly machined surfaces. Internal pressurisation makes them compliant, both for the range of movement required and with their speed of response being faster than elastomeric O-rings. Their flexure is also unaffected by temperature.The Space Shuttle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

O-ring

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, forming a seal at the interface. The O-ring may be used in static applications or in dynamic applications where there is relative motion between the parts and the O-ring. Dynamic examples include rotating pump shafts and hydraulic cylinder pistons. Static applications of O-rings may include fluid or gas sealing applications in which: (1) the O-ring is compressed resulting in zero clearance, (2) the O-ring material is vulcanized solid such that it is impermeable to the fluid or gas, and (3) the O-ring material is resistant to degradation by the fluid or gas. The wide range of potential liquids and gases that need to be sealed has necessitated the development of a wide range of materials. O-rings are one of the most common seals used i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stainless Steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corrosion resistance, resistance to corrosion results from the chromium, which forms a Passivation (chemistry), passive film that can protect the material and self-healing material, self-heal in the presence of oxygen. The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into Sheet metal, sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products. The biological cleanability of stainless steel is superior to both alumi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wet Liner

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attached. Modern engine blocks typically have the crankcase integrated with the cylinder block as a single component. Engine blocks often also include elements such as coolant passages and oil galleries. The term "cylinder block" is often used interchangeably with "engine block", although technically, the block of a modern engine (i.e. multiple cylinders integrated with another component) would be classified as a monobloc. __TOC__ Construction The main structure of an engine typically consists of the cylinders, coolant passages, oil galleries, crankcase, and cylinder head(s). The first production engines of the 1880s to 1920s usually used separate components for each of these elements, which were bolted together during engine assembly. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coventry Climax

Coventry Climax was a British forklift truck, fire pump, racing, and other specialty engine manufacturer. History Pre WW1 The company was started in 1903 as Lee Stroyer, but two years later, following the departure of Stroyer, it was relocated to Paynes Lane, Coventry, and renamed as Coventry-Simplex by H. Pelham Lee, a former Daimler Company, Daimler employee, who saw a need for competition in the nascent piston engine market. An early user was GWK (car), GWK, who produced over 1,000 light cars with Coventry-Simplex two-cylinder engines between 1911 and 1915. Just before the First world war, First World War, a Coventry-Simplex engine was used by Lionel Martin to power the first Aston Martin car. Ernest Shackleton selected Coventry-Simplex to power the tractors that were to be used in his Imperial Trans-Antarctic Expedition of 1914. Hundreds of Coventry-Simplex engines were manufactured during the First World War to be used in generating sets for searchlights. Post WW1 In 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hillman Imp

The Hillman Imp is a small economy car that was made by the Rootes Group and its successor Chrysler Europe from 1963 until 1976. Revealed on 3 May 1963, after much advance publicity, it was the first British mass-produced car with the engine block and cylinder head cast in aluminium. Being a direct competitor to the BMC's Mini, it used a space-saving rear-engine, rear-wheel-drive layout to allow as much luggage and passenger capacity as possible in both the rear and the front of the car. It used a unique opening rear hatch to allow luggage to be put into the back seat rest. It was the first mass-produced British car with the engine in the back and the first to use a diaphragm spring clutch. The baulk-ring synchromesh unit for the transaxle compensated for the speeds of gear and shaft before engagement, from which the Mini had suffered during its early production years. It incorporated many design features which were uncommon. Among them were a folding rear bench seat, autom ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coventry Climax

Coventry Climax was a British forklift truck, fire pump, racing, and other specialty engine manufacturer. History Pre WW1 The company was started in 1903 as Lee Stroyer, but two years later, following the departure of Stroyer, it was relocated to Paynes Lane, Coventry, and renamed as Coventry-Simplex by H. Pelham Lee, a former Daimler Company, Daimler employee, who saw a need for competition in the nascent piston engine market. An early user was GWK (car), GWK, who produced over 1,000 light cars with Coventry-Simplex two-cylinder engines between 1911 and 1915. Just before the First world war, First World War, a Coventry-Simplex engine was used by Lionel Martin to power the first Aston Martin car. Ernest Shackleton selected Coventry-Simplex to power the tractors that were to be used in his Imperial Trans-Antarctic Expedition of 1914. Hundreds of Coventry-Simplex engines were manufactured during the First World War to be used in generating sets for searchlights. Post WW1 In 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Piston Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons ( piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle ( jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, know ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

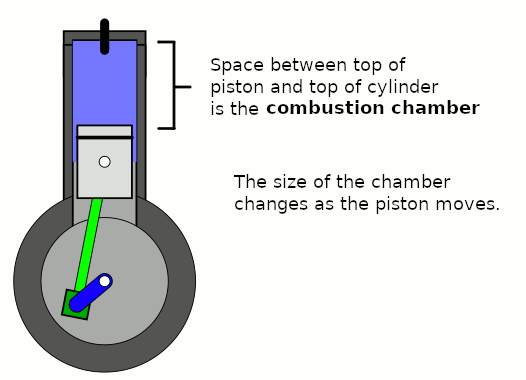

Combustion Chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process. Internal combustion engines In an internal combustion engine, the pressure caused by the burning air/fuel mixture applies direct force to part of the engine (e.g. for a piston engine, the force is applied to the top of the piston), which converts the gas pressure into mechanical energy (often in the form of a rotating output shaft). This contrasts an external combustion engine, where the combustion takes place in a separate part of the engine to where the gas pressure is converted into mechanical energy. Spark-ignition engines In spark ignition engines, such as petrol (gasoline) engines, the combustion chamber is usually located in the cylinder head. The engines are often designed such that the bottom of combustion chamber is roughly in li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PTFE

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. It is one of the best-known and widely applied PFAS. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a spin-off from DuPont, which originally discovered the compound in 1938. Polytetrafluoroethylene is a fluorocarbon solid, as it is a high-molecular-weight polymer consisting wholly of carbon and fluorine. PTFE is hydrophobic: neither water nor water-containing substances wet PTFE, as fluorocarbons exhibit only small London dispersion forces due to the low electric polarizability of fluorine. PTFE has one of the lowest coefficients of friction of any solid. Polytetrafluoroethylene is used as a non-stick coating for pans and other cookware. It is non-reactive, partly because of the strength of carbon–fluorine bonds, so it is often used in containers and pipework for reactive and corrosive chemicals. Where used as a lubricant, PTFE ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inconel

Inconel is a registered trademark of Special Metals Corporation for a family of austenitic nickel-chromium-based superalloys. Inconel alloys are oxidation-corrosion-resistant materials well suited for service in extreme environments subjected to pressure and heat. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminium and steel would succumb to creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.INCONEL alloy 718 Special Metals Corporation Inconel alloys are typical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Refractory Metal

Refractory metals are a class of metals that are extraordinarily resistant to heat and wear. The expression is mostly used in the context of materials science, metallurgy and engineering. The definition of which elements belong to this group differs. The most common definition includes five elements: two of the fifth period (niobium and molybdenum) and three of the sixth period (tantalum, tungsten, and rhenium). They all share some properties, including a melting point above 2000 °C and high hardness at room temperature. They are chemically inert and have a relatively high density. Their high melting points make powder metallurgy the method of choice for fabricating components from these metals. Some of their applications include tools to work metals at high temperatures, wire filaments, casting molds, and chemical reaction vessels in corrosive environments. Partly due to the high melting point, refractory metals are stable against creep deformation to very high temperatu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Head Gasket

In an internal combustion engine, a head gasket provides the seal between the engine block and cylinder head(s). Its purpose is to seal the combustion gases within the cylinders and to avoid coolant or engine oil leaking into the cylinders. Leaks in the head gasket can cause poor engine running and/or overheating. Purpose Within a water-cooled internal combustion engine, there are three fluids which travel between the engine block and the cylinder head: # Combustion gases (unburned air/fuel mixture and exhaust gases) in each cylinder # Water-based coolant in the coolant passages # Lubricating oil in the oil galleries Correct operation of the engine requires that each of these circuits do not leak or lose pressure at the junction of the engine block and the cylinder head. The head gasket is the seal that prevents these leaks and pressure losses. Types * Multi-Layer Steel (MLS): Most modern engines are produced with MLS gaskets. These consist of two to five (typically three) th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |