|

Conradson Carbon Residue

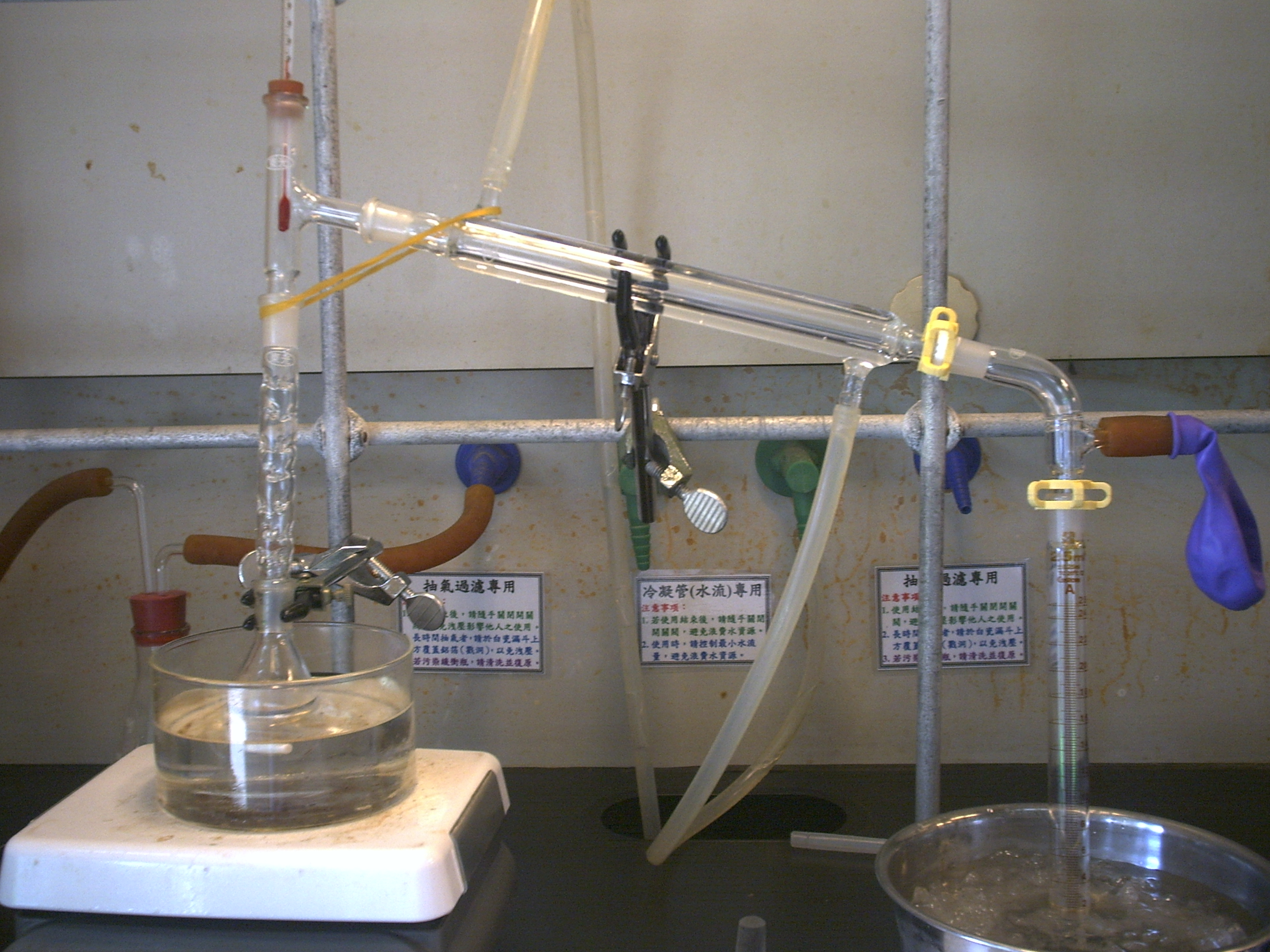

Conradson carbon residue, commonly known as "Concarbon" or "CCR" is a laboratory test used to provide an indication of the coke-forming tendencies of an oil. Quantitatively, the test measures the amount of carbonaceous residue remaining after the oil's evaporation and pyrolysis. In general, the test is applicable to petroleum products which are relatively non-volatile, and which decompose on distillation at atmospheric pressure. The phrase "Conradson carbon residue" and its common names can refer to either the test or the numerical value obtained from it. Test method A quantity of sample is weighed, placed in a crucible, and subjected to destructive distillation. During a fixed period of severe heating, the residue undergoes cracking and coking reactions . At the termination of the heating period, the crucible containing the carbonaceous residue is cooled in a desiccator and weighed. The residue remaining is calculated as a percentage of the original sample, and reported as Conrad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Petroleum Coke

Petroleum coke, abbreviated coke or petcoke, is a final carbon-rich solid material that derives from oil refining, and is one type of the group of fuels referred to as cokes. Petcoke is the coke that, in particular, derives from a final cracking process—a thermo-based chemical engineering process that splits long chain hydrocarbons of petroleum into shorter chains—that takes place in units termed coker units. (Other types of coke are derived from coal.) Stated succinctly, coke is the "carbonization product of high-boiling hydrocarbon fractions obtained in petroleum processing (heavy residues)". Petcoke is also produced in the production of synthetic crude oil (syncrude) from bitumen extracted from Canada’s oil sands and from Venezuela's Orinoco oil sands. In petroleum coker units, residual oils from other distillation processes used in petroleum refining are treated at a high temperature and pressure leaving the petcoke after driving off gases and volatiles, and separa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Evaporation

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. High concentration of the evaporating substance in the surrounding gas significantly slows down evaporation, such as when humidity affects rate of evaporation of water. When the molecules of the liquid collide, they transfer energy to each other based on how they collide. When a molecule near the surface absorbs enough energy to overcome the vapor pressure, it will escape and enter the surrounding air as a gas. When evaporation occurs, the energy removed from the vaporized liquid will reduce the temperature of the liquid, resulting in evaporative cooling. On average, only a fraction of the molecules in a liquid have enough heat energy to escape from the liquid. The evaporation will continue until an equilibrium is reached when the evaporation of the liquid is equal to its condensation. In an enclosed environment, a liquid will evaporate until the surrounding air is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements ''pyro'' "fire", "heat", "fever" and '' lysis'' "separating". Pyrolysis is most commonly used in the treatment of organic materials. It is one of the processes involved in charring wood.''Burning of wood'' , InnoFireWood's website. Accessed on 2010-02-06. In general, pyrolysis of organic substances produces volatile products and leaves , a carbon-rich solid residue. Extreme pyrolysis, which leaves mostly |

Cracking (chemistry)

In petrochemistry, petroleum geology and organic chemistry, cracking is the process whereby complex organic molecules such as kerogens or long-chain hydrocarbons are broken down into simpler molecules such as light hydrocarbons, by the breaking of carbon-carbon bonds in the precursors. The rate of cracking and the end products are strongly dependent on the temperature and presence of catalysts. Cracking is the breakdown of a large alkane into smaller, more useful alkenes. Simply put, hydrocarbon cracking is the process of breaking a long chain of hydrocarbons into short ones. This process requires high temperatures. More loosely, outside the field of petroleum chemistry, the term "cracking" is used to describe any type of splitting of molecules under the influence of heat, catalysts and solvents, such as in processes of destructive distillation or pyrolysis. Fluid catalytic cracking produces a high yield of petrol and LPG, while hydrocracking is a major source of jet fuel, die ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Fuel

Diesel fuel , also called diesel oil, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a result of compression of the inlet air and then injection of fuel. Therefore, diesel fuel needs good compression ignition characteristics. The most common type of diesel fuel is a specific fractional distillate of petroleum fuel oil, but alternatives that are not derived from petroleum, such as biodiesel, biomass to liquid (BTL) or gas to liquid (GTL) diesel are increasingly being developed and adopted. To distinguish these types, petroleum-derived diesel is sometimes called petrodiesel in some academic circles. In many countries, diesel fuel is standardised. For example, in the European Union, the standard for diesel fuel is EN 590. Diesel fuel has many colloquial names; most commonly, it is simply referred to as ''diesel''. In the United Kingdom, diesel fuel for on-road use is c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Motor Oil

Motor oil, engine oil, or engine lubricant is any one of various substances used for the lubrication of internal combustion engines. They typically consist of base oils enhanced with various additives, particularly antiwear additives, detergents, dispersants, and, for multi-grade oils, viscosity index improvers. The main function of motor oil is to reduce friction and wear on moving parts and to clean the engine from sludge (one of the functions of dispersants) and varnish (detergents). It also neutralizes acids that originate from fuel and from oxidation of the lubricant (detergents), improves sealing of piston rings, and cools the engine by carrying heat away from moving parts. In addition to the aforementioned basic constituents, almost all lubricating oils contain corrosion and oxidation inhibitors. Motor oil may be composed of only a lubricant base stock in the case of non- detergent oil, or a lubricant base stock plus additives to improve the oil's detergency, extreme p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Oil

Gas is one of the four fundamental states of matter (the others being solid, liquid, and plasma). A pure gas may be made up of individual atoms (e.g. a noble gas like neon), elemental molecules made from one type of atom (e.g. oxygen), or compound molecules made from a variety of atoms (e.g. carbon dioxide). A gas mixture, such as air, contains a variety of pure gases. What distinguishes a gas from liquids and solids is the vast separation of the individual gas particles. This separation usually makes a colourless gas invisible to the human observer. The gaseous state of matter occurs between the liquid and plasma states, the latter of which provides the upper temperature boundary for gases. Bounding the lower end of the temperature scale lie degenerative quantum gases which are gaining increasing attention. High-density atomic gases super-cooled to very low temperatures are classified by their statistical behavior as either Bose gases or Fermi gases. For a comprehensive ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Delayed Coker

A delayed coker is a type of coker whose process consists of heating a residual oil feed to its thermal cracking temperature in a furnace with multiple parallel passes. This cracks the heavy, long chain hydrocarbon molecules of the residual oil into coker gas oil and petroleum coke. Delayed coking is one of the unit processes used in many oil refineries. The adjacent photograph depicts a delayed coking unit with 4 drums. However, larger units have tandem pairs of drums, some with as many as 8 drums, each of which may have diameters of up to 10 meters and overall heights of up to 43 meters. The yield of coke from the delayed coking process ranges from about 18 to 30 percent by weight of the feedstock residual oil, depending on the composition of the feedstock and the operating variables. Many refineries worldwide produce as much as 2,000 to 3,000 tons per day of petroleum coke and some produce even more. Schematic flow diagram and description The flow diagram and description in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid Catalytic Cracking

Fluid Catalytic Cracking (FCC) is the conversion process used in petroleum refineries to convert the high-boiling point, high-molecular weight hydrocarbon fractions of petroleum (crude oils) into gasoline, olefinic gases, and other petroleum products. The cracking of petroleum hydrocarbons was originally done by thermal cracking, now virtually replaced by catalytic cracking, which yields greater volumes of high octane rating gasoline; and produces by-product gases, with more carbon-carbon double bonds (i.e. olefins), that are of greater economic value than the gases produced by thermal cracking. The feedstock to the FCC conversion process usually is heavy gas oil (HGO), which is that portion of the petroleum (crude oil) that has an initial boiling-point temperature of or higher, at atmospheric pressure, and that has an average molecular weight that ranges from about 200 to 600 or higher; heavy gas oil also is known as “heavy vacuum gas oil” (HVGO). In the fluid catalytic cra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ramsbottom Carbon Residue

Ramsbottom carbon residue (RCR) is well known in the petroleum industry as a method to calculate the carbon residue of a fuel. The carbon residue value is considered by some to give an approximate indication of the combustibility and deposit forming tendencies of the fuel. The carbon residue of a fuel The Ramsbottom test is used to measure carbon residues of an oil. In brief, the carbon residue of a fuel is the tendency to form carbon deposits under high temperature conditions in an inert atmosphere. This is an important value for the crude oil refinery, and usually one of the measurements in a . ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Petroleum Technology

Petroleum, also known as crude oil, or simply oil, is a naturally occurring yellowish-black liquid mixture of mainly hydrocarbons, and is found in geological formations. The name ''petroleum'' covers both naturally occurring unprocessed crude oil and petroleum products that consist of refined crude oil. A fossil fuel, petroleum is formed when large quantities of dead organisms, mostly zooplankton and algae, are buried underneath sedimentary rock and subjected to both prolonged heat and pressure. Petroleum is primarily recovered by oil drilling. Drilling is carried out after studies of structural geology, sedimentary basin analysis, and reservoir characterisation. Recent developments in technologies have also led to exploitation of other unconventional reserves such as oil sands and oil shale. Once extracted, oil is refined and separated, most easily by distillation, into innumerable products for direct use or use in manufacturing. Products include fuels such as gasoline ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Geochemical Processes

Geochemistry is the science that uses the tools and principles of chemistry to explain the mechanisms behind major geological systems such as the Earth's crust and its oceans. The realm of geochemistry extends beyond the Earth, encompassing the entire Solar System, and has made important contributions to the understanding of a number of processes including mantle convection, the formation of planets and the origins of granite and basalt. It is an integrated field of chemistry and geology. History The term ''geochemistry'' was first used by the Swiss-German chemist Christian Friedrich Schönbein in 1838: "a comparative geochemistry ought to be launched, before geognosy can become geology, and before the mystery of the genesis of our planets and their inorganic matter may be revealed." However, for the rest of the century the more common term was "chemical geology", and there was little contact between geologists and chemists. Geochemistry emerged as a separate discipline aft ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |