|

Completion (oil Well)

Well completion is the process of making a well ready for production (or injection) after drilling operations. This principally involves preparing the bottom of the hole to the required specifications, running in the production tubing and its associated down hole tools as well as perforating and stimulating as required. Sometimes, the process of running in and cementing the casing is also included. After a well has been drilled, should the drilling fluids be removed, the well would eventually close in upon itself. Casing ensures that this will not happen while also protecting the wellstream from outside incumbents, like water or sand. Lower completion (downhole completion) This refers to the portion of the well across the production or injection zone. The well designer has many tools and options available to design the lower completion (downhole completion) according to the conditions of the reservoir. Typically, the lower completion is set across the productive zone using a liner ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

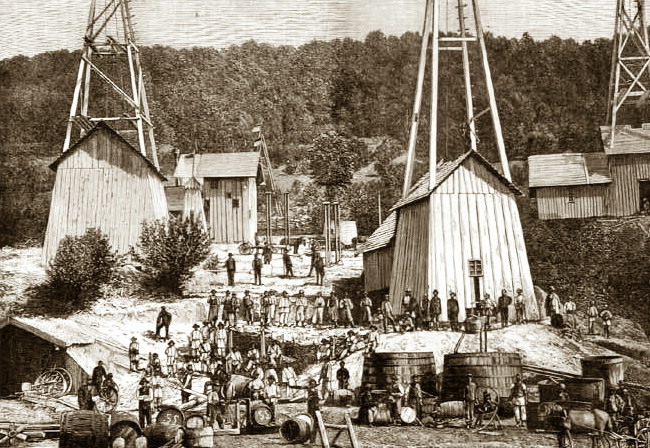

Oil Well

An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas may be termed a gas well. Wells are created by drilling down into an oil or gas reserve that is then mounted with an extraction device such as a pumpjack which allows extraction from the reserve. Creating the wells can be an expensive process, costing at least hundreds of thousands of dollars, and costing much more when in hard to reach areas, e.g., when creating offshore oil platforms. The process of modern drilling for wells first started in the 19th century, but was made more efficient with advances to oil drilling rigs during the 20th century. Wells are frequently sold or exchanged between different oil and gas companies as an asset – in large part because during falls in price of oil and gas, a well may be unproductive, but if price ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Lift

Gas lift or bubble pumps use the artificial lift technique of raising a fluid such as water or oil by introducing bubbles of compressed air, water vapor or other vaporous bubbles into the outlet tube. This has the effect of reducing the hydrostatic pressure in the outlet tube vs. the hydrostatic pressure at the inlet side of the tube. Devices using this type of lift mechanism: *Coffee percolators and electric drip coffeemakers use vaporized water to lift hot water *Airlift pumps uses compressed air to lift water *Pulser pumps use a subterranean chamber of air for an airlift pump * Suction dredges use an airlift pump to vacuum mud, sand and debris *Mist lift pumps uses vaporized water to lift seawater in Ocean thermal energy conversion Petroleum industry uses In the United States, gas lift is used in 10% of the oil wells that have insufficient reservoir pressure to produce the well. In the petroleum industry, the process involves injecting gas through the tubing-casing annulus. I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Proppant

A proppant is a solid material, typically sand, treated sand or man-made ceramic materials, designed to keep an induced hydraulic fracture open, during or following a fracturing treatment, most commonly for unconventional reservoirs. It is added to a ''fracking fluid'' which may vary in composition depending on the type of fracturing used, and can be gel, foam or slickwater–based. In addition, there may be unconventional fracking fluids. Fluids make tradeoffs in such material properties as viscosity, where more viscous fluids can carry more concentrated proppant; the energy or pressure demands to maintain a certain flux pump rate (flow velocity) that will conduct the proppant appropriately; pH, various rheological factors, among others. In addition, fluids may be used in low-volume well stimulation of high-permeability sandstone wells (20k to 80k gallons per well) to the high-volume operations such as shale gas and tight gas that use millions of gallons of water per well. Co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Fracturing

Fracking (also known as hydraulic fracturing, hydrofracturing, or hydrofracking) is a well stimulation technique involving the fracturing of bedrock formations by a pressurized liquid. The process involves the high-pressure injection of "fracking fluid" (primarily water, containing sand or other proppants suspended with the aid of thickening agents) into a wellbore to create cracks in the deep-rock formations through which natural gas, petroleum, and brine will flow more freely. When the hydraulic pressure is removed from the well, small grains of hydraulic fracturing proppants (either sand or aluminium oxide) hold the fractures open. Hydraulic fracturing began as an experiment in 1947, and the first commercially successful application followed in 1950. As of 2012, 2.5 million "frac jobs" had been performed worldwide on oil and gas wells, over one million of those within the U.S. Such treatment is generally necessary to achieve adequate flow rates in shale gas, tight gas, tig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Well

An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas may be termed a gas well. Wells are created by drilling down into an oil or gas reserve that is then mounted with an extraction device such as a pumpjack which allows extraction from the reserve. Creating the wells can be an expensive process, costing at least hundreds of thousands of dollars, and costing much more when in hard to reach areas, e.g., when creating offshore oil platforms. The process of modern drilling for wells first started in the 19th century, but was made more efficient with advances to oil drilling rigs during the 20th century. Wells are frequently sold or exchanged between different oil and gas companies as an asset – in large part because during falls in price of oil and gas, a well may be unproductive, but if price ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Perforation (oil Well)

A perforation in the context of oil wells refers to a hole punched in the casing or liner of an oil well to connect it to the reservoir. Creating a channel between the pay zone and the wellbore to cause oil and gas to flow to the wellbore easily. In cased hole completions, the well will be drilled down past the section of the formation desired for production and will have casing or a liner run in separating the formation from the well bore. The final stage of the completion will involve running in perforating guns, a string of shaped charges, down to the desired depth and firing them to perforate the casing or liner. A typical perforating gun can carry many dozens of explosive charges. Commonly, perforation guns are run on E-line as it is traditional to use electrical signals from the surface to fire the guns. In more highly deviated wells, coiled tubing may be used. Newer technologies allow the guns to be run on slickline. Modern slickline technology embeds fiber-optic lines t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Limescale

Limescale is a hard, chalky deposit, consisting mainly of calcium carbonate (CaCO3). It often builds up inside kettles, boilers, and pipework, especially that for hot water. It is also often found as a similar deposit on the inner surfaces of old pipes and other surfaces where "hard water" has flown. Limescale also forms as travertine or tufa in hard water springs. The colour varies from off-white through a range of greys and pink or reddish browns, depending on the other minerals present. Iron compounds give the reddish-browns. In addition to being unsightly and hard to clean, limescale can seriously damage or impair the operation of various plumbing and heating components.Hermann Weingärtner, "Water" in ''Ullmann's Encyclopedia of Industrial Chemistry'', December 2006, Wiley–VCH, Weinheim. Descaling agents are commonly used to remove limescale. Prevention of fouling by scale build-up relies on the technologies of water softening or other water treatment. Chemical compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrocarbons

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and hydrophobic, and their odors are usually weak or exemplified by the odors of gasoline and lighter fluid. They occur in a diverse range of molecular structures and phases: they can be gases (such as methane and propane), liquids (such as hexane and benzene), low melting solids (such as paraffin wax and naphthalene) or polymers (such as polyethylene and polystyrene). In the fossil fuel industries, ''hydrocarbon'' refers to the naturally occurring petroleum, natural gas and coal, and to their hydrocarbon derivatives and purified forms. Combustion of hydrocarbons is the main source of the world's energy. Petroleum is the dominant raw-material source for organic commodity chemicals such as solvents and polymers. Most anthropogenic (human-generated) emissions of greenhouse gases are carb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrochloric Acid

Hydrochloric acid, also known as muriatic acid, is an aqueous solution of hydrogen chloride. It is a colorless solution with a distinctive pungent smell. It is classified as a strong acid Acid strength is the tendency of an acid, symbolised by the chemical formula HA, to dissociate into a proton, H+, and an anion, A-. The dissociation of a strong acid in solution is effectively complete, except in its most concentrated solutions .... It is a component of the gastric acid in the digestive systems of most animal species, including humans. Hydrochloric acid is an important laboratory reagent and industrial chemical. History In the early tenth century, the Persian physician and alchemist Abu Bakr al-Razi ( 865–925, Latin: Rhazes) conducted experiments with sal ammoniac (ammonium chloride) and vitriol (hydrated sulfates of various metals), which he distilled together, thus producing the gas hydrogen chloride. In doing so, al-Razi may have stumbled upon a primitive method ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Well Kill

A well kill is the operation of placing a column of heavy fluid into a well bore in order to prevent the flow of reservoir fluids without the need for pressure control equipment at the surface. It works on the principle that the hydrostatic head of the "kill fluid" or "kill mud" will be enough to suppress the pressure of the formation fluids. Well kills may be planned in the case of advanced interventions such as workovers, or be contingency operations. The situation calling for a well kill will dictate the method taken. Not all well kills are deliberate. Sometimes, the unintended buildup of fluids, either from injection of chemicals like methanol from surface, or from liquids produced from the reservoir, can be enough to kill the well, particularly gas wells, which are notoriously easy to kill. Well control in general is an extremely expensive and dangerous operation. Extensive training, testing, proof of competence, and experience are prerequisites for planning and performing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Optical Fiber

An optical fiber, or optical fibre in Commonwealth English, is a flexible, transparent fiber made by drawing glass (silica) or plastic to a diameter slightly thicker than that of a human hair. Optical fibers are used most often as a means to transmit light between the two ends of the fiber and find wide usage in fiber-optic communications, where they permit transmission over longer distances and at higher bandwidths (data transfer rates) than electrical cables. Fibers are used instead of metal wires because signals travel along them with less loss; in addition, fibers are immune to electromagnetic interference, a problem from which metal wires suffer. Fibers are also used for illumination and imaging, and are often wrapped in bundles so they may be used to carry light into, or images out of confined spaces, as in the case of a fiberscope. Specially designed fibers are also used for a variety of other applications, some of them being fiber optic sensors and fiber lasers. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Production Tubing

Production tubing is a tube used in a wellbore through which production fluids are produced (travel). Background Production tubing is run into the drilled well after the casing is run and cemented in place. Production tubing protects wellbore casing from wear, tear, corrosion, and deposition of by-products, such as sand / silt, paraffins, and asphaltenes. Along with other components that constitute the production string, it provides a continuous bore from the production zone to the wellhead through which oil and gas can be produced. It is usually between five and ten centimeters in diameter and is held inside the casing through the use of expandable packing devices. Purpose and design of production tubing is to enable quick, efficient, and safe installation, removal and re-installation. If there is more than one zone of production in the well, up to four lines of production tubing can be run. Production casing Production casing is the final casing string set in a well and usua ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |