|

Chisels

A chisel is a tool with a characteristically shaped cutting edge (such that wood chisels have lent part of their name to a particular grind) of blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or of wood with a sharp edge in it. Chiselling use involves forcing the blade into some material to cut it. The driving force may be applied by pushing by hand, or by using a mallet or hammer. In industrial use, a hydraulic ram or falling weight ('trip hammer') may be used to drive a chisel into the material. A gouge (one type of chisel) serves to carve small pieces from the material, particularly in woodworking, woodturning and sculpture. Gouges most frequently produce concave surfaces. A gouge typically has a 'U'-shaped cross-section. Etymology ''Chisel'' comes from the Old French ''cisel'', modern ''ciseau'', Late Latin ''cisellu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood Chisel

A chisel is a tool with a characteristically shaped cutting edge (such that wood chisels have lent part of their name to a particular grind) of blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or of wood with a sharp edge in it. Chiselling use involves forcing the blade into some material to cut it. The driving force may be applied by pushing by hand, or by using a mallet or hammer. In industrial use, a hydraulic ram or falling weight ('trip hammer') may be used to drive a chisel into the material. A gouge (one type of chisel) serves to carve small pieces from the material, particularly in woodworking, woodturning and sculpture. Gouges most frequently produce concave surfaces. A gouge typically has a 'U'-shaped cross-section. Etymology ''Chisel'' comes from the Old French ''cisel'', modern ''ciseau'', Late Latin ''cisell ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chisel

A chisel is a tool with a characteristically shaped cutting edge (such that wood chisels have lent part of their name to a particular grind) of blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or of wood with a sharp edge in it. Chiselling use involves forcing the blade into some material to cut it. The driving force may be applied by pushing by hand, or by using a mallet or hammer. In industrial use, a hydraulic ram or falling weight ('trip hammer') may be used to drive a chisel into the material. A gouge (one type of chisel) serves to carve small pieces from the material, particularly in woodworking, woodturning and sculpture. Gouges most frequently produce concave surfaces. A gouge typically has a 'U'-shaped cross-section. Etymology ''Chisel'' comes from the Old French ''cisel'', modern ''ciseau'', Late Latin ''cisel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Framing Slick

A slick is a large chisel, characterized by a wide (2-4 inches, 5–10 cm), heavy blade, and a long, frequently slender, socketed handle. A long, flat metal plate fitted with an offset handle. The combined blade and handle can reach two feet (60 cm) in length. The blade of a slick is slightly curved lengthwise, and/or the handle socket is cranked upward, such that the handle and socket clear the surface of the work when the edge is touching. This distinguishes the slick from the similarly sized, short-handled millwright's chisel. Use A slick is always pushed; never struck (thus the slender handle). Using a combination of the tool's weight and bracing the handle against the shoulder or upper arm, fine paring cuts are made. Slicks are typically used by shipwright Shipbuilding is the construction of ships and other floating vessels. It normally takes place in a specialized facility known as a shipyard. Shipbuilders, also called shipwrights, follow a specialized occu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

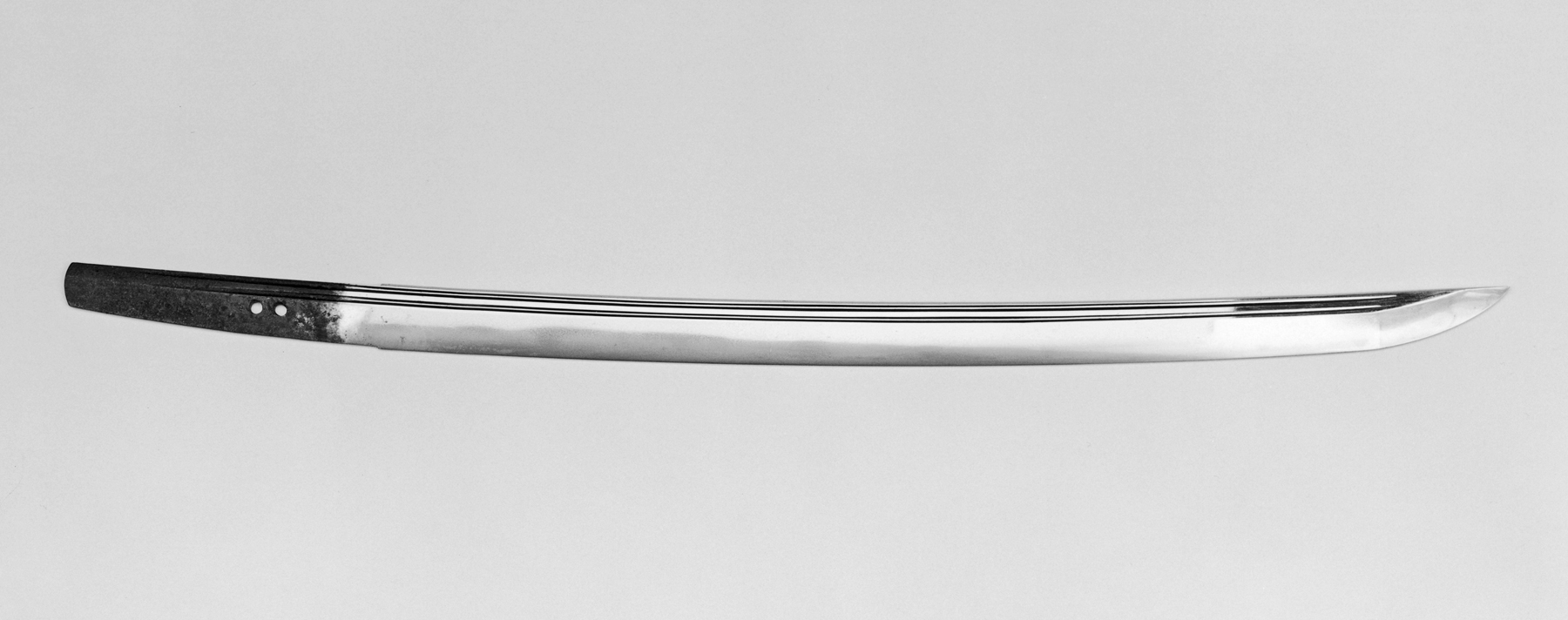

Blade

A blade is the portion of a tool, weapon, or machine with an edge that is designed to puncture, chop, slice or scrape surfaces or materials. Blades are typically made from materials that are harder than those they are to be used on. Historically, humans have made blades from flaking stones such as flint or obsidian, and from various metal such as copper, bronze and iron. Modern blades are often made of steel or ceramic. Blades are one of humanity's oldest tools, and continue to be used for combat, food preparation, and other purposes. Blades work by concentrating force on the cutting edge. Certain blades, such as those used on bread knives or saws, are serrated, further concentrating force on the point of each tooth. Uses During food preparation, knives are mainly used for slicing, chopping, and piercing. In combat, a blade may be used to slash or puncture, and may also be thrown or otherwise propelled. The function is to sever a nerve, muscle or tendon fibers, or bloo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slick (tool)

A slick is a large chisel, characterized by a wide (2-4 inches, 5–10 cm), heavy blade, and a long, frequently slender, socketed handle. A long, flat metal plate fitted with an offset handle. The combined blade and handle can reach two feet (60 cm) in length. The blade of a slick is slightly curved lengthwise, and/or the handle socket is cranked upward, such that the handle and socket clear the surface of the work when the edge is touching. This distinguishes the slick from the similarly sized, short-handled millwright's chisel. Use A slick is always pushed; never struck (thus the slender handle). Using a combination of the tool's weight and bracing the handle against the shoulder or upper arm, fine paring cuts are made. Slicks are typically used by shipwright Shipbuilding is the construction of ships and other floating vessels. It normally takes place in a specialized facility known as a shipyard. Shipbuilders, also called shipwrights, follow a specialized occu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corner Chisel

A corner chisel is a tool for cutting sharp internal corners in wood, often used for mortice joints or hinge rebates. The hole will typically be cut by a router, or occasionally drilled, leaving rounded corners. The function of the corner chisel is therefore similar to the square morticing chisel used on a morticing machine. {{Woodworking, state=collapsed Woodworking chisels Chisels ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

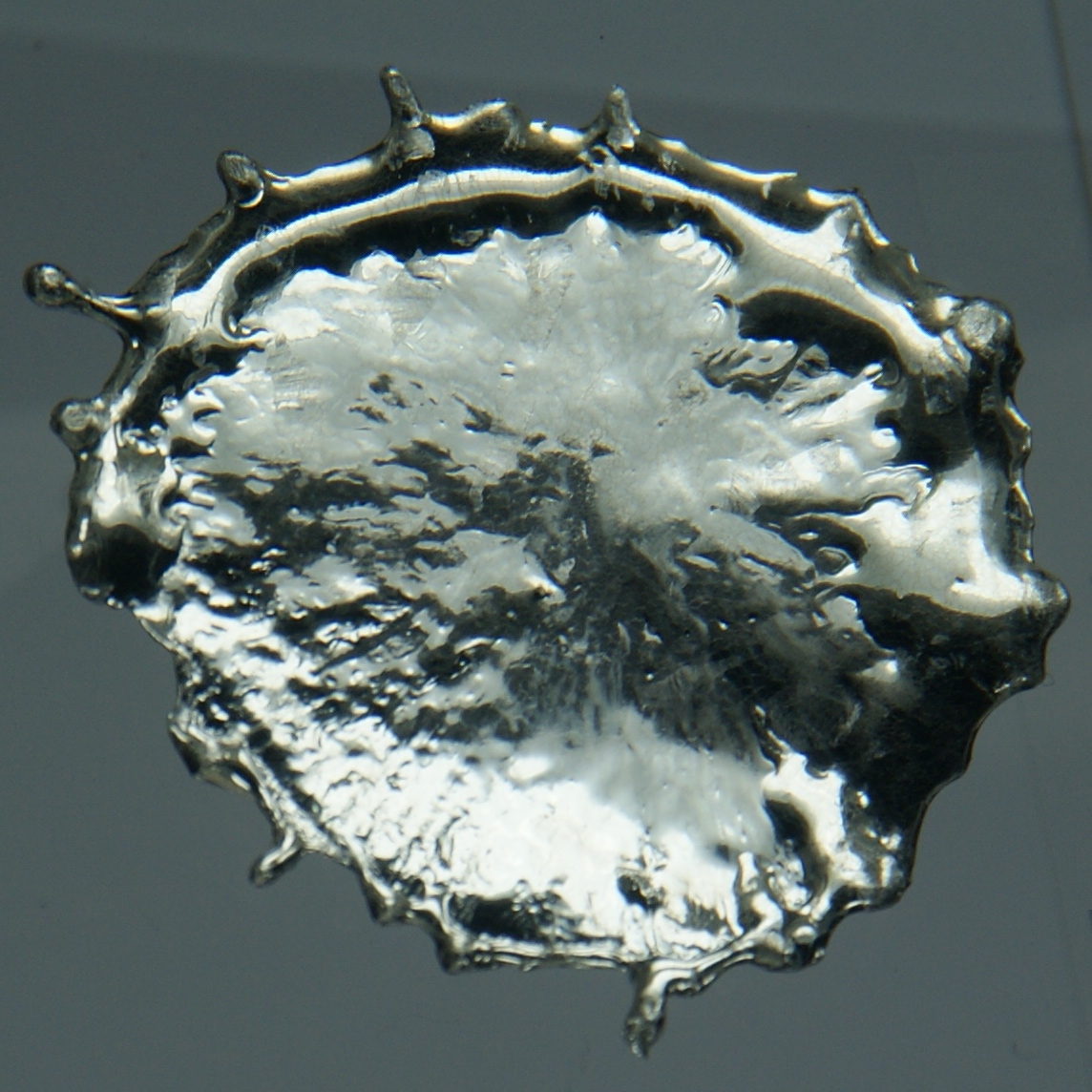

Beryllium Copper

Beryllium copper (BeCu), also known as copper beryllium (CuBe), beryllium bronze, and spring copper, is a copper alloy with 0.5–3% beryllium but can contain other elements as well. Beryllium copper combines high strength with non- magnetic and non-sparking qualities. It has excellent metalworking, forming, and machining properties. It has many specialized applications in tools for hazardous environments, musical instruments, precision measurement devices, bullets, and aerospace. Beryllium alloys present a toxic inhalation hazard during manufacture. Properties Beryllium copper is a ductile, weldable, and machinable alloy. Like pure copper, it is resistant to non-oxidizing acids (such as hydrochloric acid and carbonic acid) and plastic decomposition products, to abrasive wear, and to galling. It can be heat-treated for increased strength, durability, and electrical conductivity. Beryllium copper attains the greatest strength (up to ) of any copper-based alloy. It has ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tin Snips

Tin is a chemical element with the symbol Sn (from la, stannum) and atomic number 50. Tin is a silvery-coloured metal. Tin is soft enough to be cut with little force and a bar of tin can be bent by hand with little effort. When bent, the so-called "tin cry" can be heard as a result of twinning in tin crystals; this trait is shared by indium, cadmium, zinc, and mercury in the solid state. Pure tin after solidifying presents a mirror-like appearance similar to most metals. In most tin alloys (such as pewter) the metal solidifies with a dull gray color. Tin is a post-transition metal in group 14 of the Periodic table, periodic table of elements. It is obtained chiefly from the mineral cassiterite, which contains Tin(IV) oxide, stannic oxide, . Tin shows a chemical similarity to both of its neighbors in group 14, germanium and lead, and has two main oxidation states, +2 and the slightly more stable +4. Tin is the 49th most abundant element on Earth and has, with 10 s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sledgehammer

A sledgehammer is a tool with a large, flat, often metal head, attached to a long handle. The long handle combined with a heavy head allows the sledgehammer to gather momentum during a swing and apply a large force compared to hammers designed to drive nails. Along with the mallet, it shares the ability to distribute force over a wide area. This is in contrast to other types of hammers, which concentrate force in a relatively small area. Etymology The word sledgehammer is derived from the Anglo Saxon "''slægan''", which, in its first sense, means "to strike violently". The English words "slag", "slay", and "slog" are cognates. Uses The handle can range from to a full long, depending on the mass of the head. The head mass is usually . Modern heavy duty sledgehammers come with heads. Sledgehammers usually require two hands and a swinging motion involving the entire torso, in contrast to smaller hammers used for driving in nails. The combination of a long swinging range ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tempered Steel

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered at much higher temperatures. Introduction Tempering is a heat treatment technique applied to ferrous alloys, such as steel or cast iron, to achieve greater toughness by decreasing the hardness of the alloy. The reduction in hardness is usually accompanied by an increase in ductility, thereby decreasing the brittleness of the metal. Tempering is usually performed after quenchi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe (tool)

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, Deformation (engineering), deformation, facing (machining), facing, and turning, with tools that are applied to the workpiece to create an object with rotational symmetry, symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most Solid of revolution, solids of revolution, plane surfaces and screw threads or helix, helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other wo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)