|

Cathodic Arc Deposition

{{Short description, Type of physical vapor deposition technique Cathodic arc deposition or Arc-PVD is a physical vapor deposition technique in which an electric arc is used to vaporize material from a cathode target. The vaporized material then condenses on a substrate, forming a thin film. The technique can be used to deposit metallic, ceramic, and composite films. History Industrial use of modern cathodic arc deposition technology originated in Soviet Union around 1960–1970. By the late 70's Soviet government released the use of this technology to the West. Among many designs in USSR at that time the design by L. P. Sablev, et al., was allowed to be used outside the USSR. Process The arc evaporation process begins with the striking of a high current, low voltage arc on the surface of a cathode (known as the target) that gives rise to a small (usually a few micrometres wide), highly energetic emitting area known as a cathode spot. The localised temperature at the cathode spot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Physical Vapor Deposition

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polymers. PVD is characterized by a process in which the material transitions from a condensed phase to a vapor phase and then back to a thin film condensed phase. The most common PVD processes are sputtering and evaporation. PVD is used in the manufacturing of items which require thin films for optical, mechanical, electrical, acoustic or chemical functions. Examples include semiconductor devices such as thin-film solar cells, microelectromechanical devices such as thin film bulk acoustic resonator, aluminized PET film for food packaging and balloons, and titanium nitride coated cutting tools for metalworking. Besides PVD tools for fabrication, special smaller tools used mainly for scientific purposes have been developed. The source material i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dissociation (chemistry)

Dissociation in chemistry is a general process in which molecules (or ionic compounds such as salts, or complexes) separate or split into other things such as atoms, ions, or radicals, usually in a reversible manner. For instance, when an acid dissolves in water, a covalent bond between an electronegative atom and a hydrogen atom is broken by heterolytic fission, which gives a proton (H+) and a negative ion. Dissociation is the opposite of association or recombination. Dissociation constant For reversible dissociations in a chemical equilibrium :AB A + B the dissociation constant ''K''d is the ratio of dissociated to undissociated compound :K_d = \mathrm where the brackets denote the equilibrium concentrations of the species. Dissociation degree The dissociation degree \alpha is the fraction of original solute molecules that have dissociated. It is usually indicated by the Greek symbol α. More accurately, degree of dissociation refers to the amount of solute dissociated i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

TiAlN

Titanium aluminium nitride (TiAlN) or aluminium titanium nitride (AlTiN; for aluminium contents higher than 50%) is a group of metastable hard coatings consisting of nitrogen and the metallic elements aluminium and titanium. Four important compositions (metal content 100 wt.%) are deposited in industrial scale by physical vapor deposition methods: * Ti50Al50N (industrially introduced by the company CemeCoat (now CemeCon) Aachen, BRD, group T. Leydecker ca. 1989) * Al55Ti45N (industrially introduced by the company Metaplas Ionon (now Oerlikon), Bergisch Gladbach, BRD, group J. Vetter ca. 1999) * Al60Ti40N (industrially introduced by the company Kobe Steel, Kobe, Japan, ca. 1992) * Al66Ti34N (industrially introduced by the company Metaplas (now Oerlikon) group J. Vetter ca. 1996). The fundamental reasons why TiAlN coatings outperform pure Titanium nitride (TiN) coatings are considered to be: * Increased oxidation resistance at elevated temperatures due to the formation of a protecti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanocomposite

Nanocomposite is a multiphase solid material where one of the phases has one, two or three dimensions of less than 100 nanometers (nm) or structures having nano-scale repeat distances between the different phases that make up the material. The idea behind Nanocomposite is to use building blocks with dimensions in nanometre range to design and create new materials with unprecedented flexibility and improvement in their physical properties. In the broadest sense this definition can include porous media, colloids, gels and copolymers, but is more usually taken to mean the solid combination of a bulk matrix and nano-dimensional phase(s) differing in properties due to dissimilarities in structure and chemistry. The mechanical, electrical, thermal, optical, electrochemical, catalytic properties of the nanocomposite will differ markedly from that of the component materials. Size limits for these effects have been proposed: in Kelly, A, ''Concise encyclopedia of composites materials'', El ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Superhard Coatings

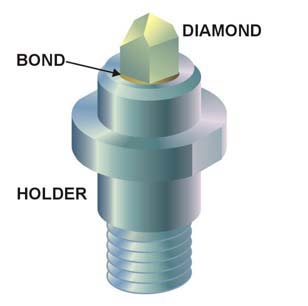

A superhard material is a material with a hardness value exceeding 40 gigapascals (GPa) when measured by the Vickers hardness test. They are virtually incompressible solids with high electron density and high bond covalency. As a result of their unique properties, these materials are of great interest in many industrial areas including, but not limited to, abrasives, polishing and cutting tools, disc brakes, and wear-resistant and protective coatings. Diamond is the hardest known material to date, with a Vickers hardness in the range of 70–150 GPa. Diamond demonstrates both high thermal conductivity and electrically insulating properties, and much attention has been put into finding practical applications of this material. However, diamond has several limitations for mass industrial application, including its high cost and oxidation at temperatures above 800 °C. In addition, diamond dissolves in iron and forms iron carbides at high temperatures and therefore is inefficien ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasma (physics)

Plasma () 1, where \nu_ is the electron gyrofrequency and \nu_ is the electron collision rate. It is often the case that the electrons are magnetized while the ions are not. Magnetized plasmas are ''anisotropic'', meaning that their properties in the direction parallel to the magnetic field are different from those perpendicular to it. While electric fields in plasmas are usually small due to the plasma high conductivity, the electric field associated with a plasma moving with velocity \mathbf in the magnetic field \mathbf is given by the usual Lorentz force, Lorentz formula \mathbf = -\mathbf\times\mathbf, and is not affected by Debye shielding. Mathematical descriptions To completely describe the state of a plasma, all of the particle locations and velocities that describe the electromagnetic field in the plasma region would need to be written down. However, it is generally not practical or necessary to keep track of all the particles in a plasma. Therefore, plasma physicist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |