|

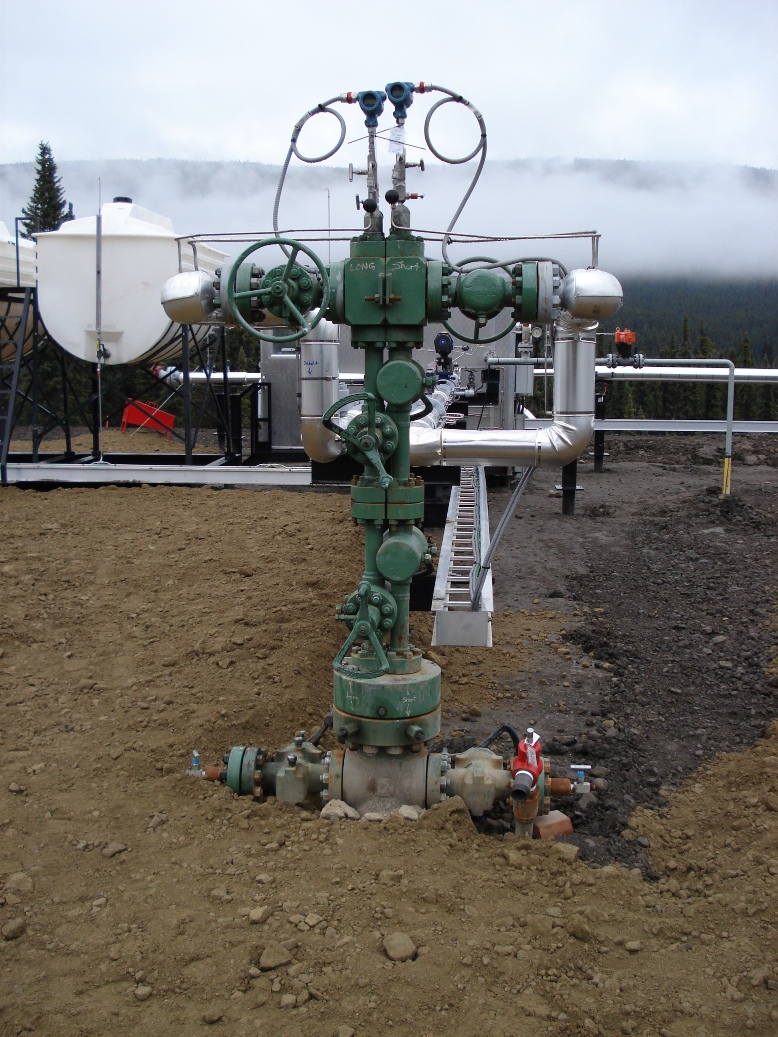

Casing Head

In oil drilling, a casing head is a simple metal flange welded or screwed onto the top of the conductor pipe (also known as ''drive-pipe'') or the casing and forms part of the wellhead system for the well. This is the primary interface for the surface pressure control equipment, for example blowout preventers (for well drilling) or the Christmas tree (for well production). The casing head, when installed, is typically tested to very strict pressure and leak-off parameters to insure viability under blowout conditions, before any surface equipment is installed. See also *Drilling rig (petroleum) This article lists the main components of a petroleum onshore drilling rig. Offshore drilling rigs have similar elements, but are configured with a number of different drilling systems to suit drilling in the marine environment. The equipment a ... for a diagram. References Oilfield terminology Drilling technology Petroleum engineering {{Petroleum-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flange

A flange is a protruded ridge, lip or rim (wheel), rim, either external or internal, that serves to increase shear strength, strength (as the flange of an iron beam (structure), beam such as an I-beam or a T-beam); for easy attachment/transfer of contact force with another object (as the flange on the end of a pipe (fluid conveyance), pipe, steam cylinder, etc., or on the lens mount of a camera); or for stabilizing and guiding the movements of a machine or its parts (as the inside flange of a railroad car, rail car or tram train wheel, wheel, which keep the wheels from derailment, running off the rail profile, rails). Flanges are often attached using bolts in the pattern of a bolt circle. The term "flange" is also used for a kind of tool used to form flanges. Plumbing or piping A flange can also be a plate or ring to form a rim at the end of a pipe when fastened to the pipe (for example, a closet flange). A blind flange is a plate for covering or closing the end of a pipe. A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conductor Pipe

A conductor Pipe is a large diameter pipe that is set into the ground to provide the initial stable structural foundation for a borehole or oil well. The Conductor pipe is the first string of casing and is the largest diameter casing to be installed in a well. It can also be referred to as a ''drive pipe'' because it is often ''driven'' into the ground with a pile driver. Conductor pipe is typically set, on petroleum wells, before any drilling operations are performed. It is usually set with special pile-driving or rigs, though the drilling rig is sometimes used to save time and money. Conductor pipe’s purpose is to protect shallow sands from being contaminated by drilling fluids, and to help prevent washouts (which occur near the surface due to loose and unconsolidated top soils, gravel beds, etc.). In the offshore drilling industry, the conductor pipe is set in the seabed, and is a key structural foundation for the subsea wellhead. When drilling an offshore well, a marine ris ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casing (borehole)

Casing is a large diameter pipe that is assembled and inserted into a recently drilled section of a borehole. Similar to the bones of a spine protecting the spinal cord, casing is set inside the drilled borehole to protect and support the wellstream. The lower portion (and sometimes the entirety) is typically held in place with cement. Deeper strings usually are not cemented all the way to the surface, so the weight of the pipe must be partially supported by a casing hanger in the wellhead. Casing that is cemented in place aids the drilling process in several ways: * Prevents contamination of fresh water well zones. * Prevents unstable upper formations from caving in and sticking the drill string or forming large caverns. * Provides a strong upper foundation to allow use of high-density drilling fluid to continue drilling deeper. * Isolates various zones, which may have different pressures or fluids, in the drilled formations from one another. * Seals off high pressure zones ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wellhead

A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. The primary purpose of a wellhead is to provide the suspension point and pressure seals for the casing strings that run from the bottom of the hole sections to the surface pressure control equipment. While drilling the oil well, surface pressure control is provided by a blowout preventer (BOP). If the pressure is not contained during drilling operations by the column of drilling fluid, casings, wellhead, and BOP, a well blowout could occur. When the well has been drilled, it is completed to provide an interface with the reservoir rock and a tubular conduit for the well fluids. The surface pressure control is provided by a Christmas tree, which is installed on top of the wellhead, with isolation valves and choke equipment to control the flow of well fluids during production. Wellheads are typically welded on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blowout Preventer

A blowout preventer (BOP) (pronounced B-O-P, not "bop") is a specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves. Blowout preventers were developed to cope with extreme erratic pressures and uncontrolled flow ( formation kick) emanating from a well reservoir during drilling. Kicks can lead to a potentially catastrophic event known as a blowout. In addition to controlling the downhole (occurring in the drilled hole) pressure and the flow of oil and gas, blowout preventers are intended to prevent tubing (e.g. drill pipe and well casing), tools and drilling fluid from being blown out of the wellbore (also known as bore hole, the hole leading to the reservoir) when a blowout threatens. Blowout preventers are critical to the safety of crew, rig (the equipment system used to drill a wellbore) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Christmas Tree (oil Well)

In petroleum and natural gas extraction, a Christmas tree, or "tree", is an assembly of valves, casing spools, and fittings used to regulate the flow of pipes in an oil well, gas well, water injection well, water disposal well, gas injection well, condensate well, and other types of well. Overview The first primitive Christmas Tree was used by the Hamill Brothers to bring Spindletop under control. It consisted of a T-valve, with a and valve on the vertical pipe, and a 6-inch valve on the horizontal pipe. The vertical valve was closed first, and then the valve to the horizontal pipe. Christmas trees are used on both surface and subsea wells. It is common to identify the type of tree as either "subsea tree" or "surface tree". Each of these classifications has a number of variations. Examples of subsea include conventional, dual bore, mono bore, TFL (through flow line), horizontal, mudline, mudline horizontal, side valve, and TBT (through-bore tree) trees. The deepest install ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blowout (well Drilling)

A blowout is the uncontrolled release of crude oil and/or natural gas from an oil well or gas well after pressure control systems have failed.'All About Blowout', R. Westergaard, Norwegian Oil Review, 1987 Modern wells have blowout preventers intended to prevent such an occurrence. An accidental spark during a blowout can lead to a catastrophic oil or gas fire. Prior to the advent of pressure control equipment in the 1920s, the uncontrolled release of oil and gas from a well while drilling was common and was known as an oil gusher, gusher or wild well. History Gushers were an icon of oil exploration during the late 19th and early 20th centuries. During that era, the simple drilling techniques, such as cable-tool drilling, and the lack of blowout preventers meant that drillers could not control high-pressure reservoirs. When these high-pressure zones were breached, the oil or natural gas would travel up the well at a high rate, forcing out the drill string and creating a gus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling Rig (petroleum)

This article lists the main components of a petroleum onshore drilling rig. Offshore drilling rigs have similar elements, but are configured with a number of different drilling systems to suit drilling in the marine environment. The equipment associated with a rig is to some extent dependent on the type of rig but typically includes at least some of the items listed below. {{clear List of items #Mud tank #Shale shakers # Suction line (mud pump) #Mud pump #Motor or power source #hose #Drawworks # Standpipe #Kelly hose # Goose-neck # Traveling block # Drill line #Crown block #Derrick # Racking Board (Sometimes referred to as the Monkey Board) #Stand (of drill pipe) # Setback (floor) #Swivel (On newer rigs this may be replaced by a top drive) #Kelly drive #Rotary table #Drill floor #Bell nipple #Blowout preventer (BOP) Annular type #Blowout preventer (BOP) Pipe ram & blind ram #Drill string #Drill bit #Casing head or Wellhead #Flow line Explanation *Bell nipple (#22) is a sectio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oilfield Terminology

Oilfield terminology refers to the jargon used by those working in fields within and related to the upstream segment of the petroleum industry. It includes words and phrases describing professions, equipment, and procedures specific to the industry. It may also include slang terms used by oilfield workers to describe the same. Examples *Bell nipple: An enlarged pipe at the top of a casing string that serves as a funnel to guide drilling tools into the top of the well. *Big bear: A big bear is a hitch (see hitch) that lasts a minimum of 50 straight days. *Black Leg : Joints of pipe racked back in the derrick. * Blowout: A sudden, uncontrolled release of underground pressure from the well. *BOP (Blowout preventer): Pronounced "B-O-P", not "bop", is a mechanical device connected to the wellhead to control and prevent blowouts. *Catwalk: Elevated platform used for sliding pipe up to the rig floor. *Chainhand (also motorman): An experienced laborer capable of maintaining most part ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling Technology

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross section (geometry), cross-section in solid materials. The drill bit is usually a rotary Cutting tool (machining), cutting tool, often multi-point. The bit is Pressure, pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work-piece, cutting off Swarf, chips (swarf) from the hole as it is drilled. In Rock (geology), rock drilling, the hole is usually not made through a circular cutting motion, though the bit is usually rotated. Instead, the hole is usually made by hammering a drill bit into the hole with quickly repeated short movements. The hammering action can be performed from outside the hole (top-hammer drill) or within the hole (down-the-hole drill, DTH). Drills used for horizontal drilling are called drifter drills. In rare cases, specially-shaped bits are used to cut holes of non-circular cro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |