|

Cam Engine

A cam engine is a reciprocating engine where, instead of the conventional crankshaft, the pistons deliver their force to a cam that is then caused to rotate. The output work of the engine is driven by this cam. Cam engines are deeply rooted in history. The first engine to get an airworthiness certificate from the United States government was, in fact, a radial cam engine. A variation of the cam engine, the swashplate engine (also the closely related wobble-plate engine), was briefly popular. These are generally thought of as internal combustion engines, although they have also been used as hydraulic- and pneumatic motors. Hydraulic motors, particularly the swashplate form, are widely and successfully used. Internal combustion engines, though, remain almost unknown. Operation Operating cycle Some cam engines are two-stroke engines, rather than four-stroke. Two modern example are the KamTech and Earthstar, both radial-cam engines. In a two-stroke engine, the forces on the pisto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reciprocating Engine

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.''Thermodynamics: An Engineering Approach'' by Yunus A. Cengal and Michael A. Boles Common features in all types There may be one or more pistons. Each piston is inside a cylinder, into which a gas is intr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thrust Block

A thrust block, also known as a thrust box, is a specialised form of thrust bearing used in ships, to resist the thrust of the propeller shaft and transmit it to the hull. Early thrust boxes Early screw-propelled steamships used a thrust block or ''thrust box'' composed of perhaps a dozen lower-rated plain thrust journal bearings stacked on the same shaft. These were problematic in service: they were bulky, difficult to dismantle, wasted power through friction and they had a tendency to overheat. The thrust box was built of a box-like cast iron housing with a radial bearing at each end and a number of collars formed on the shaft between them. This shaft was often a short section of removable shaft called the ''thrust shaft'', linking the engine ahead to the propeller shaft astern. A series of iron horseshoe-shaped collars fitted over the small diameter of the shaft and bore against the forward face of the shaft's collars. Each horseshoe was faced with a low-friction pad of babbit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Two-stroke Engines

A two-stroke (or two-stroke cycle) engine is a type of internal combustion engine that completes a power cycle with two strokes (up and down movements) of the piston during one power cycle, this power cycle being completed in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle during two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust (or scavenging) functions occurring at the same time. Two-stroke engines often have a high power-to-weight ratio, power being available in a narrow range of rotational speeds called the power band. Two-stroke engines have fewer moving parts than four-stroke engines. History The first commercial two-stroke engine involving cylinder compression is attributed to Scotland, Scottish engineer Dugald Clerk, who patented his design in 1881. However, unlike most lat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

National Advisory Committee For Aeronautics

The National Advisory Committee for Aeronautics (NACA) was a United States federal agency founded on March 3, 1915, to undertake, promote, and institutionalize aeronautical research. On October 1, 1958, the agency was dissolved and its assets and personnel were transferred to the newly created National Aeronautics and Space Administration (NASA). NACA is an initialism, i.e., pronounced as individual letters, rather than as a whole word (as was NASA during the early years after being established). Among other advancements, NACA research and development produced the NACA duct, a type of air intake used in modern automotive applications, the NACA cowling, and several series of NACA airfoils, which are still used in aircraft manufacturing. During World War II, NACA was described as "The Force Behind Our Air Supremacy" due to its key role in producing working superchargers for high altitude bombers, and for producing the laminar wing profiles for the North American P-51 Mustang. NA ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

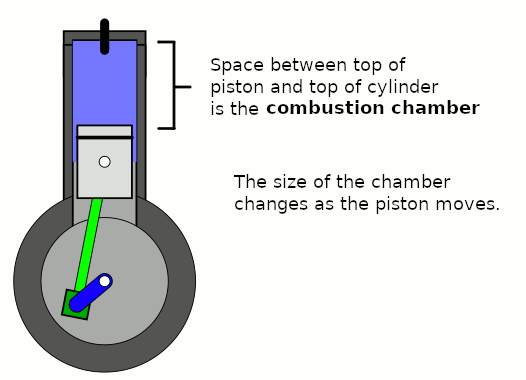

Combustion Chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process. Internal combustion engines In an internal combustion engine, the pressure caused by the burning air/fuel mixture applies direct force to part of the engine (e.g. for a piston engine, the force is applied to the top of the piston), which converts the gas pressure into mechanical energy (often in the form of a rotating output shaft). This contrasts an external combustion engine, where the combustion takes place in a separate part of the engine to where the gas pressure is converted into mechanical energy. Spark-ignition engines In spark ignition engines, such as petrol (gasoline) engines, the combustion chamber is usually located in the cylinder head. The engines are often designed such that the bottom of combustion chamber is roughly in li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rand Cam Engine

The RAND Corporation (from the phrase "research and development") is an American nonprofit global policy think tank created in 1948 by Douglas Aircraft Company to offer research and analysis to the United States Armed Forces. It is financed by the U.S. government and private endowment, corporations, universities and private individuals. The company assists other governments, international organizations, private companies and foundations with a host of defense and non-defense issues, including healthcare. RAND aims for interdisciplinary and quantitative problem solving by translating theoretical concepts from formal economics and the physical sciences into novel applications in other areas, using applied science and operations research. Overview RAND has approximately 1,850 employees. Its American locations include: Santa Monica, California (headquarters); Arlington, Virginia; Pittsburgh, Pennsylvania; and Boston, Massachusetts. The RAND Gulf States Policy Institute has an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wankel Engine

The Wankel engine (, ) is a type of internal combustion engine using an Eccentric (mechanism), eccentric rotary combustion engine, rotary design to convert pressure into rotating motion. It was invented by German engineer Felix Wankel, and designed by German engineer Hanns-Dieter Paschke. The Wankel engine's rotor, which creates the turning motion, is similar in shape to a Reuleaux triangle, with the sides having less curvature. The rotor rotates inside an oval-like epitrochoidal housing, around a central output shaft. The rotor spins in a hula-hoop fashion around the central output shaft, spinning the shaft via toothed gearing. Due to its inherent poor thermodynamics, the Wankel engine has a significantly worse thermal efficiency and worse exhaust gas behaviour when compared against the Otto engine or the Diesel engine, which is why the Wankel engine has seen limited use since its introduction in the 1960s. However, its advantages of compact design, smoothness, lower weight and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

James Watt

James Watt (; 30 January 1736 (19 January 1736 OS) – 25 August 1819) was a Scottish inventor, mechanical engineer, and chemist who improved on Thomas Newcomen's 1712 Newcomen steam engine with his Watt steam engine in 1776, which was fundamental to the changes brought by the Industrial Revolution in both his native Great Britain and the rest of the world. While working as an instrument maker at the University of Glasgow, Watt became interested in the technology of steam engines. He realised that contemporary engine designs wasted a great deal of energy by repeatedly cooling and reheating the cylinder. Watt introduced a design enhancement, the separate condenser, which avoided this waste of energy and radically improved the power, efficiency, and cost-effectiveness of steam engines. Eventually, he adapted his engine to produce rotary motion, greatly broadening its use beyond pumping water. Watt attempted to commercialise his invention, but experienced great financial di ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pistonless Rotary Engine

A pistonless rotary engine is an internal combustion engine that does not use pistons in the way a reciprocating engine does. Designs vary widely but typically involve one or more rotors, sometimes called rotary pistons. Although many different designs have been constructed, only the Wankel engine has achieved widespread adoption. The term rotary combustion engine has been used as a name for these engines to distinguish them from early (generally up to the early 1920s) aircraft engines and motorcycle engines also known as ''rotary engines''. However, both continue to be called ''rotary engines'' and only the context determines which type is meant, whereas the "pistonless" prefix is less ambiguous. Pistonless rotary engines A pistonless rotary engine replaces the linear reciprocating motion of a piston with more complex compression/expansion motions with the objective of improving some aspect of the engine's operation, such as: higher efficiency thermodynamic cycles, lower mecha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nutation (engineering)

In engineering, a nutating motion is similar to that seen in a swashplate mechanism. In general, a nutating plate is carried on a skewed bearing on the main shaft and does not itself rotate, whereas a swashplate is fixed to the shaft and rotates with it. The motion is similar to the motions of coin or a tire wobbling on the ground after being dropped with the flat side down. ''Precession'' is the physical term for this kind of motion. Nutating mixers are used in gentle three-dimensional (gyrating) agitation of chemical or biological scientific procedures by repetitively moving the vessels holding the liquids. The nutating motion is widely employed in flowmeters and pumps. The displacement of volume for one revolution is first determined. The speed of the device in revolutions per unit time is measured. In the case of flowmeters, the product of the rotational speed and the displacement per revolution is then taken to find the flow rate. A nutating disc engine was patented in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aircraft Engine

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years many small UAVs have used electric motors. Manufacturing industry In commercial aviation the major Western manufacturers of turbofan engines are Pratt & Whitney (a subsidiary of Raytheon Technologies), General Electric, Rolls-Royce, and CFM International (a joint venture of Safran Aircraft Engines and General Electric). Russian manufacturers include the United Engine Corporation, Aviadvigatel and Klimov. Aeroengine Corporation of China was formed in 2016 with the merger of several smaller companies. The largest manufacturer of turboprop engines for general aviation is Pratt & Whitney. General Electric announced in 2015 entrance into the market. Development history * 1848: John Stringfellow made a steam engine for a 10-foot wingspan mod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Axial Engine

Axial engines (sometimes known as barrel or Z-crank engines) are a type of reciprocating engine A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common featu ... with pistons arranged around an output shaft with their axes parallel to the shaft. Barrel refers to the cylindrical shape of the cylinder group (result of the pistons being spaced evenly around the central crankshaft and aligned parallel to the crankshaft axis) whilst the Z-crank alludes to the shape of the crankshaft. The key advantage of the axial design is that the cylinders are arranged in parallel around the output/crank shaft in contrast to radial and inline engines, both types having cylinders at right angles to the shaft. As a result, it is a very compact, cylindrical engine, allowing variation in compression ratio of the engine w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |