|

Cadillac Twin-turbo V8

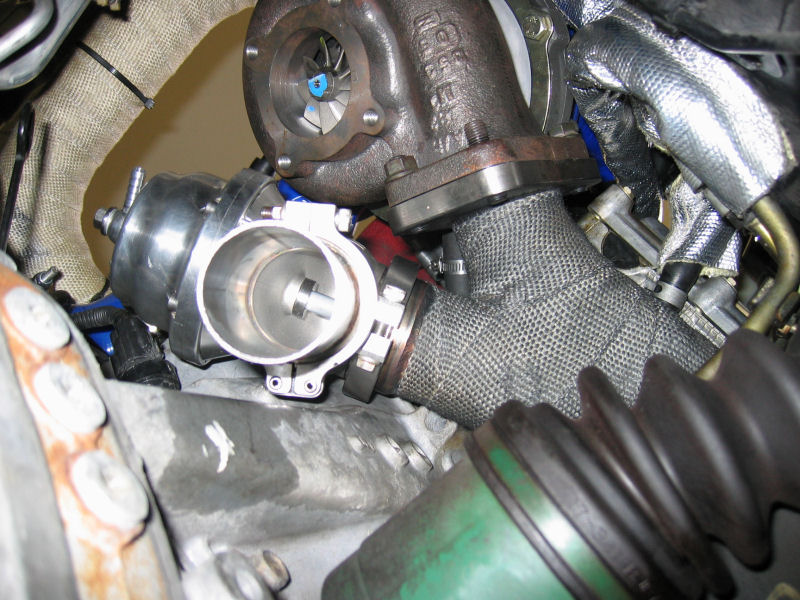

The Cadillac Blackwing V8 (GM RPO ''LTA'') is a twin-turbo DOHC V8 engine that was produced by the Cadillac Division of General Motors for use in its CT6-V between 2018 and early 2020. It is a clean sheet engine design, as well as the Division's first ever twin-turbo V8 engine. The engine was branded as the "Blackwing V8" by GM technicians, and is the first Cadillac-exclusive dual overhead cam V8 engine since the Northstar V8 was dropped in 2011. The aluminum cylinder block features pressed-in iron liners, cross-bolted main bearing caps and houses a lightweight forged steel crankshaft, forged steel connecting rods and high strength hypereutectic aluminum pistons. There are four sodium-filled valves per cylinder. The intercooled turbochargers are mounted between the cylinder banks in a so-called hot-V configuration and their twin scroll design broadens their performance capability, offering quicker response and greater efficiency. These produce up to and are matched with electr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cadillac

The Cadillac Motor Car Division () is a division of the American automobile manufacturer General Motors (GM) that designs and builds luxury vehicles. Its major markets are the United States, Canada, and China. Cadillac models are distributed in 34 additional markets worldwide. Cadillac automobiles are at the top of the luxury field within the United States. In 2019, Cadillac sold 390,458 vehicles worldwide, a record for the brand. Cadillac is among the first automotive brands in the world, fourth in the United States only to Autocar Company (1897) and fellow GM marques Oldsmobile (1897) and Buick (1899). It was named after Antoine de la Mothe Cadillac (1658–1730), who founded Detroit, Michigan. The Cadillac crest is based on his coat of arms. By the time General Motors purchased the company in 1909, Cadillac had already established itself as one of America's premier luxury car makers. The complete interchangeability of its precision parts had allowed it to lay the foundati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Block

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attached. Modern engine blocks typically have the crankcase integrated with the cylinder block as a single component. Engine blocks often also include elements such as coolant passages and oil galleries. The term "cylinder block" is often used interchangeably with "engine block", although technically, the block of a modern engine (i.e. multiple cylinders integrated with another component) would be classified as a monobloc. __TOC__ Construction The main structure of an engine typically consists of the cylinders, coolant passages, oil galleries, crankcase, and cylinder head(s). The first production engines of the 1880s to 1920s usually used separate components for each of these elements, which were bolted together during engine assembly. M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automatic Transmission

An automatic transmission (sometimes abbreviated to auto or AT) is a multi-speed transmission used in internal combustion engine-based motor vehicles that does not require any input from the driver to change forward gears under normal driving conditions. It typically includes a transmission, axle, and differential in one integrated assembly, thus technically becoming a transaxle. The most common type of automatic transmission is the hydraulic automatic, which uses a planetary gearset, hydraulic controls, and a torque converter. Other types of automatic transmissions include continuously variable transmissions (CVT), automated manual transmissions (AMT), and dual-clutch transmissions (DCT). An electronic automatic transmission (EAT) may also be called an electronically controlled transmission (ECT), or electronic automatic transaxle (EATX). A hydraulic automatic transmission may also colloquially called a " slushbox" or simply a "torque converter", although the latter term c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ford-GM 10-speed Automatic Transmission

This transmission is part of a joint-venture between Ford Motor Company and General Motors to design and engineer two transmissions, a longitudinal 10-speed transmission and a transverse 9-speed trans-axle. Each company will manufacture its own unique version of the transmissions in their own factories. The 10-speed transmission was designed by Ford, while GM designed the 9-speed transmission which is used in transverse applications. Specifications Abstract A unique triple-clutch assembly on a dedicated intermediate shaft, placed in the middle of the architecture, replaces two ordinary clutches and is the key for packaging the 10-speed unit into the same space as previous transmissions. The transmission provides small steps between each gear ratio, improving performance and maximizing engine power during acceleration. A wide gear ratio spread and a lower numerical top gear ratio reduces engine speed at vehicle highway speeds, resulting in improved efficiency. Technical data Ap ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Variable Displacement

Variable displacement is an automobile engine technology that allows the engine displacement to change, usually by deactivating cylinders, for improved fuel economy. The technology is primarily used in large, multi-cylinder engines. Many automobile manufacturers have adopted this technology as of 2005, although the concept has existed for some time prior to this. Theory of operation Cylinder deactivation is used to reduce the fuel consumption and emissions of an internal combustion engine during light-load operation. In typical light-load driving the driver uses only around 30 percent of an engine’s maximum power. In these conditions, the throttle valve is nearly closed, and the engine needs to work to draw air. This causes an inefficiency known as pumping loss. Some large capacity engines need to be throttled so much at light load that the cylinder pressure at top dead centre is approximately half that of a small 4-cylinder engine. Low cylinder pressure results in lower fuel e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Variator (variable Valve Timing)

Variable valve timing (VVT) is a system for varying the valve opening of an internal combustion engine. This allows the engine to deliver high power, but also to work tractably and efficiently at low power. There are many systems for VVT, which involve changing either the relative timing, duration or opening of the engine's inlet and exhaust valves. One of the first practical VVT systems used a variator to change the phasePhase refers to the relative timing between the inlet and exhaust camshafts, expressed as an angular measure. of the camshaft and valves. This simple system cannot change the duration of the valve opening, or their lift.'Lift' is the distance by which the valves open. Later VVT systems, such as the helical camshaft or the movable fulcrum systems, could change these factors too. Despite this limitation, the variator is a relatively simple device to add to an existing engine and so they remain in service today. As the benefit of the variator relies on changing the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Throttle

A throttle is the mechanism by which fluid flow is managed by constriction or obstruction. An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle'' has come to refer, informally, to any mechanism by which the power or speed of an engine is regulated, such as a car's accelerator pedal. What is often termed a ''throttle'' (in an aviation context) is also called a thrust lever, particularly for jet engine powered aircraft. For a steam locomotive, the valve which controls the steam is known as the regulator. Internal combustion engines In an internal combustion engine, the throttle is a means of controlling an engine's power by regulating the amount of fuel or air entering the engine. In a motor vehicle the control used by the driver to regulate power is sometimes called the throttle, accelerator, or gas Automobile pedal, pedal. For a gasoline engine, the throttle most commonly regul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gasoline Direct Injection

Gasoline direct injection (GDI), also known as petrol direct injection (PDI), is a mixture formation system for internal combustion engines that run on gasoline (petrol), where fuel is injected into the combustion chamber. This is distinct from manifold fuel injection systems, which inject fuel into the intake manifold. The use of GDI can help increase engine efficiency and specific power output as well as reduce exhaust emissions. The first GDI engine to reach production was introduced in 1925 for a low-compression truck engine. Several German cars used a Bosch mechanical GDI system in the 1950s, however usage of the technology remained rare until an electronic GDI system was introduced in 1996 by Mitsubishi for mass-produced cars. GDI has seen rapid adoption by the automotive industry in recent years, increasing in the United States from 2.3% of production for model year 2008 vehicles to approximately 50% for model year 2016. Operating principle Charge modes The 'charg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wastegate

A wastegate is a valve that controls the flow of exhaust gases to the turbine wheel in a turbocharged engine system.Robson, D. (2018). Aircraft General Knowledge. Aviation Theory Centre Pty Ltd. . Diversion of exhaust gases regulates the turbine speed, which in turn regulates the rotating speed of the compressor. The primary function of the wastegate is to regulate the maximum boost pressure in turbocharger systems, to protect the engine and the turbocharger. One advantage of installing a remote mount wastegate to a free-float (or non-WG) turbo includes allowance for a smaller A/R turbine housing, resulting in less lag time before the turbo begins to spool and create boost. Wastegate types External An external wastegate is a separate self-contained mechanism typically used with turbochargers that do not have internal wastegates. An external wastegate requires a specially constructed turbo manifold with a dedicated runner going to the wastegate. The external wastegate may be pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a supercharger is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder. __TOC__ Piston engines Internal combustion engines An internal combustion engine is acted upon by the pressure of the expanding combustion gases in the combustion chamber space at the top of the cylinder. This force then acts downwards through the connecting rod and onto the crankshaft. The connecting rod is att ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hypereutectic

A eutectic system or eutectic mixture ( ) is a homogeneous mixture that has a melting point lower than those of the constituents. The lowest possible melting point over all of the mixing ratios of the constituents is called the ''eutectic temperature''. On a phase diagram, the eutectic temperature is seen as the eutectic point (see plot on the right). Non-eutectic mixture ratios would have different melting temperatures for their different constituents, since one component's lattice will melt at a lower temperature than the other's. Conversely, as a non-eutectic mixture cools down, each of its components would solidify (form a lattice) at a different temperature, until the entire mass is solid. Not all binary alloys have eutectic points, since the valence electrons of the component species are not always compatible, in any mixing ratio, to form a new type of joint crystal lattice. For example, in the silver-gold system the melt temperature (liquidus) and freeze temperature (so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)