|

CAD CAM

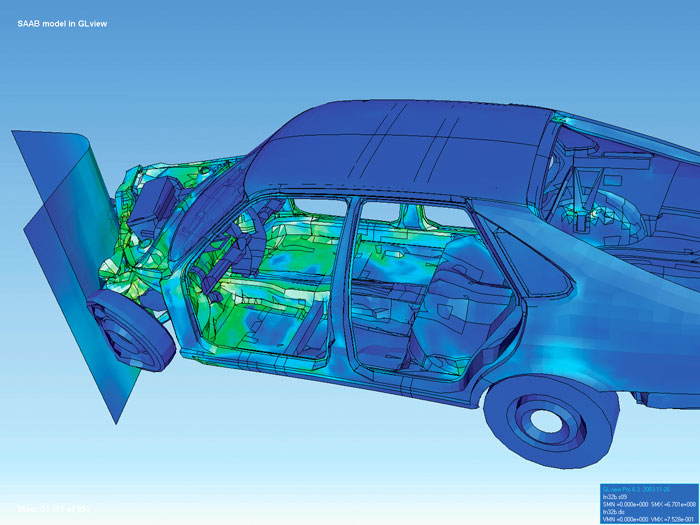

Computer-aided technologies (CAx) is the use of computer technology to aid in the design, analysis, and manufacture of products. Advanced CAx tools merge many different aspects of the product lifecycle management (PLM), including design, finite element analysis (FEA), manufacturing, production planning, product * Computer-aided design (CAD) * Computer-aided architectural design (CAAD) * Computer-aided engineering (CAE) * Computer-aided fixture design (CAFD) * Computer-aided innovation (CAI) * Computer-aided industrial design (CAID) * Computer-aided manufacturing (CAM) * Computer-aided process planning (CAPP) * Computer-aided requirements capture (CAR) * Computer-aided rule definition (CARD) * Computer-aided rule execution (CARE) * Computer-aided software engineering (CASE) * Computer-aided automation (CAA) * Computer-assisted surgery (CAS) ** Computer-aided surgical simulation (CASS) * Computational fluid dynamics (CFD) * Component information system (CIS) * Compute ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Software Engineering

Computer-aided software engineering (CASE) is the domain of software tools used to design and implement applications. CASE tools are similar to and were partly inspired by Computer-Aided Design (CAD) tools used for designing hardware products. CASE tools were used for developing high-quality, defect-free, and maintainable software. CASE software is often associated with methods for the development of information systems together with automated tools that can be used in the software development process. History The Information System Design and Optimization System (ISDOS) project, started in 1968 at the University of Michigan, initiated a great deal of interest in the whole concept of using computer systems to help analysts in the very difficult process of analysing requirements and developing systems. Several papers by Daniel Teichroew fired a whole generation of enthusiasts with the potential of automated systems development. His Problem Statement Language / Problem Statement An ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Process Planning

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed into a final ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Process Management

Manufacturing process management (MPM) is a collection of technologies and methods used to define how products are to be manufactured. MPM differs from ERP/MRP which is used to plan the ordering of materials and other resources, set manufacturing schedules, and compile cost data. A cornerstone of MPM is the central repository for the integration of all these tools and activities aids in the exploration of alternative production line scenarios; making assembly lines more efficient with the aim of reduced lead time to product launch, shorter product times and reduced work in progress (WIP) inventories as well as allowing rapid response to product or product changes. * Production process planning ** Manufacturing concept planning ** Factory layout planning and analysis *** work flow simulation. *** walk-path assembly planning *** plant design optimization ** Mixed model line balancing. ** Workloads on multiple stations. ** Process simulation tools e.g. die press lines, manufacturin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knowledge Lifecylcle Management

Knowledge can be defined as awareness of facts or as practical skills, and may also refer to familiarity with objects or situations. Knowledge of facts, also called propositional knowledge, is often defined as true belief that is distinct from opinion or guesswork by virtue of justification. While there is wide agreement among philosophers that propositional knowledge is a form of true belief, many controversies in philosophy focus on justification: whether it is needed at all, how to understand it, and whether something else besides it is needed. These controversies intensified due to a series of thought experiments by Edmund Gettier and have provoked various alternative definitions. Some of them deny that justification is necessary and replace it, for example, with reliability or the manifestation of cognitive virtues. Others contend that justification is needed but formulate additional requirements, for example, that no defeaters of the belief are present or that the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knowledge-based Engineering

Knowledge-based engineering (KBE) is the application of knowledge-based systems technology to the domain of manufacturing design and production. The design process is inherently a knowledge-intensive activity, so a great deal of the emphasis for KBE is on the use of knowledge-based technology to support computer-aided design (CAD) however knowledge-based techniques (e.g. knowledge management) can be applied to the entire product lifecycle. The CAD domain has always been an early adopter of software-engineering techniques used in knowledge-based systems, such as object-orientation and rules. Knowledge-based engineering integrates these technologies with CAD and other traditional engineering software tools. Benefits of KBE include improved collaboration of the design team due to knowledge management, improved re-use of design artifacts, and automation of major parts of the product lifecycle. Overview KBE is essentially engineering on the basis of knowledge models. A knowledge mode ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finite Element Method

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The FEM is a general numerical method for solving partial differential equations in two or three space variables (i.e., some boundary value problems). To solve a problem, the FEM subdivides a large system into smaller, simpler parts that are called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numerical domain for the solution, which has a finite number of points. The finite element method formulation of a boundary value problem finally results in a system of algebraic equations. The method approximates the unknown function over the domain. The sim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Enterprise Resource Planning

Enterprise resource planning (ERP) is the integrated management of main business processes, often in real time and mediated by software and technology. ERP is usually referred to as a category of Business management tools, business management software—typically a suite of integrated application software, applications—that an organization can use to collect, store, manage and interpret data from many business sector, business activities. ERP systems can be local based or Cloud computing, cloud-based. Cloud-based applications have grown in recent years due to information being readily available from any location with Internet access. Traditional On-premises software, on-premise ERP systems are now considered Legacy system, legacy technology. ERP provides an integrated and continuously updated view of core business processes using common databases maintained by a database management system. ERP systems track business resources—cash, raw materials, production capacity—and t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electronic Design Automation

Electronic design automation (EDA), also referred to as electronic computer-aided design (ECAD), is a category of software tools for designing Electronics, electronic systems such as integrated circuits and printed circuit boards. The tools work together in a Design flow (EDA), design flow that chip designers use to design and analyze entire semiconductor chips. Since a modern semiconductor chip can have billions of components, EDA tools are essential for their design; this article in particular describes EDA specifically with respect to integrated circuits (ICs). History Early days Prior to the development of EDA, integrated circuits were designed by hand and manually laid out. Some advanced shops used geometric software to generate tapes for a Gerber format, Gerber photoplotter, responsible for generating a monochromatic exposure image, but even those copied digital recordings of mechanically drawn components. The process was fundamentally graphic, with the translation f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer Numerical Controlled

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-integrated Manufacturing

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster and less error-prone by the integration of computers. Typically CIM relies on closed-loop control processes based on real-time input from sensors. It is also known as ''flexible design and manufacturing''. Overview # Computer-integrated manufacturing is used in automotive, aviation, space, and ship building industries. # The term "computer-integrated manufacturing" is both a method of manufacturing and the name of a computer-automated system in which individual engineering, production, marketing, and support functions of a manufacturing enterprise are organized. # In a CIM system functional areas such as design, analysis, planning, purchasing, cost accounting, inventory control, and distribution are linked through the computer with facto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Component Information System

Circuit Component may refer to: •Are devices that perform functions when they are connected in a circuit. In engineering, science, and technology Generic systems *System components, an entity with discrete structure, such as an assembly or software module, within a system considered at a particular level of analysis *Lumped element model, a model of spatially distributed systems Electrical *Component video, a type of analog video information that is transmitted or stored as two or more separate signals *Electronic components, the constituents of electronic circuits * Symmetrical components, in electrical engineering, analysis of unbalanced three-phase power systems Mathematics *Color model, a way of describing how colors can be represented, typically as multiple values or color components *Component (group theory), a quasi-simple subnormal sub-group *Connected component (graph theory), a maximal connected subgraph *Connected component (topology), a maximal connected s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |