|

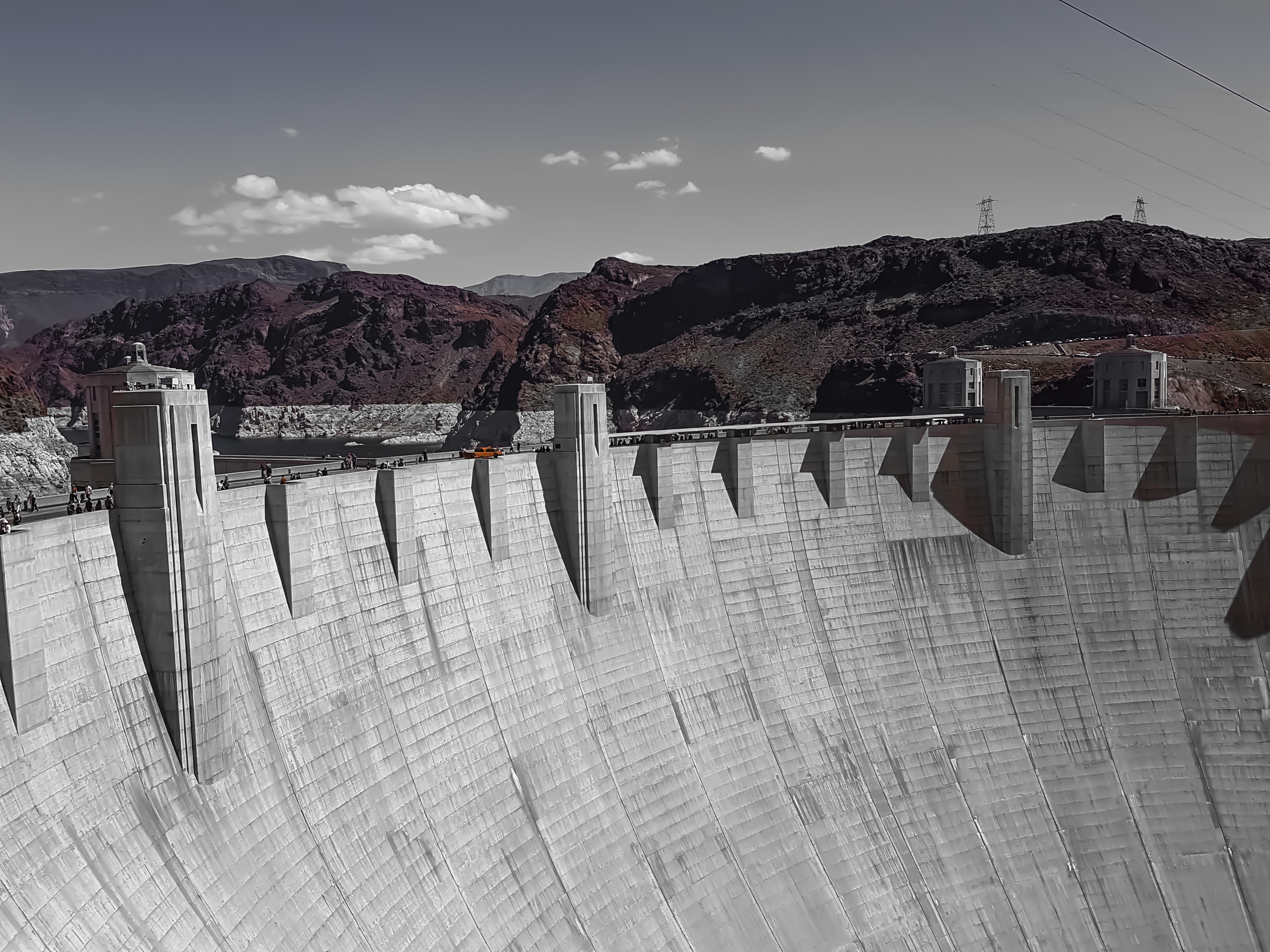

Concrete Slab

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete. Steel- reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while thinner ''mud slabs'' may be used for exterior paving . In many domestic and industrial buildings, a thick concrete slab supported on foundations or directly on the subsoil, is used to construct the ground floor. These slabs are generally classified as ''ground-bearing'' or ''suspended''. A slab is ground-bearing if it rests directly on the foundation, otherwise the slab is suspended. For multi-story buildings, there are several common slab designs : * Beam and block, also referred to as ''rib and block'', is mostly used in residential and industrial applications. This slab type is made up of pre-stressed beams and hollow blocks and are temporarily propped until set, typically after 21 days. * A hollow core slab which i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Construction Aggregate

Construction aggregate, or simply aggregate, is a broad category of coarse- to medium-grained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates. Aggregates are the most mined materials in the world. Aggregates are a component of composite materials such as concrete and asphalt; the aggregate serves as reinforcement to add strength to the overall composite material. Due to the relatively high hydraulic conductivity value as compared to most soils, aggregates are widely used in drainage applications such as foundation and French drains, septic drain fields, retaining wall drains, and roadside edge drains. Aggregates are also used as base material under foundations, roads, and railroads. In other words, aggregates are used as a stable foundation or road/rail base with predictable, uniform properties (e.g. to help prevent differential settling under the road or building), or as a low-cost exten ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rebar

Rebar (short for reinforcing bar), known when massed as reinforcing steel or reinforcement steel, is a steel bar used as a Tension (physics), tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under Compression (physics), compression, but has weak tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface features a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage. The most common type of rebar is carbon steel, typically consisting of hot-rolled round bars with deformation patterns embossed into its surface. Steel and concrete have similar coefficient of thermal expansion, coefficients of thermal expansion, so a concrete structural member reinforced with steel will experience minimal differential stress (mechanics), stress as the temperature changes. Other readily available ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deep Foundation

A deep foundation is a type of foundation that transfers building loads to the earth farther down from the surface than a shallow foundation does to a subsurface layer or a range of depths. A pile or piling is a vertical structural element of a deep foundation, driven or drilled deep into the ground at the building site. There are many reasons that a geotechnical engineer would recommend a deep foundation over a shallow foundation, such as for a skyscraper. Some of the common reasons are very large design loads, a poor soil at shallow depth, or site constraints like property lines. There are different terms used to describe different types of deep foundations including the pile (which is analogous to a pole), the pier (which is analogous to a column), drilled shafts, and caissons. Piles are generally driven into the ground in situ; other deep foundations are typically put in place using excavation and drilling. The naming conventions may vary between engineering discip ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fill Dirt

Fill dirt (also called cleanfill, or just fill) is earthy material which is used to ''fill in'' a depression or hole in the ground or create mounds or otherwise artificially change the grade or elevation of real property. , retrieved on 2008-11-12. Fill dirt is usually (soil from beneath ) and underlying soil which has little |

Cement Slab Pour

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource. Cements used in construction are usually inorganic, often lime or calcium silicate based, which can be characterized as hydraulic or the less common non-hydraulic, depending on the ability of the cement to set in the presence of water (see hydraulic and non-hydraulic lime plaster). Hydraulic cements (e.g., Portland cement) set and become adhesive through a chemical reaction between the dry ingredients and water. The chemical reaction results in mineral hydrates that are not very water-soluble and so are quite durable in wate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Concrete Slab Forms

Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminum combined. Globally, the ready-mix concrete industry, the largest segment of the concrete market, is projected to exceed $600 billion in revenue by 2025. This widespread use results in a number of environmental impacts. Most notably, the production process for cement produces large volumes of greenhouse gas emissions, leading to net 8% of global emissions. Other environmental concerns include widespread illegal sand mining, impacts on the surrounding environment such as increased surface runoff or urban heat island effect, and potential public health implications from toxic ingredients. Significant research and development is be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

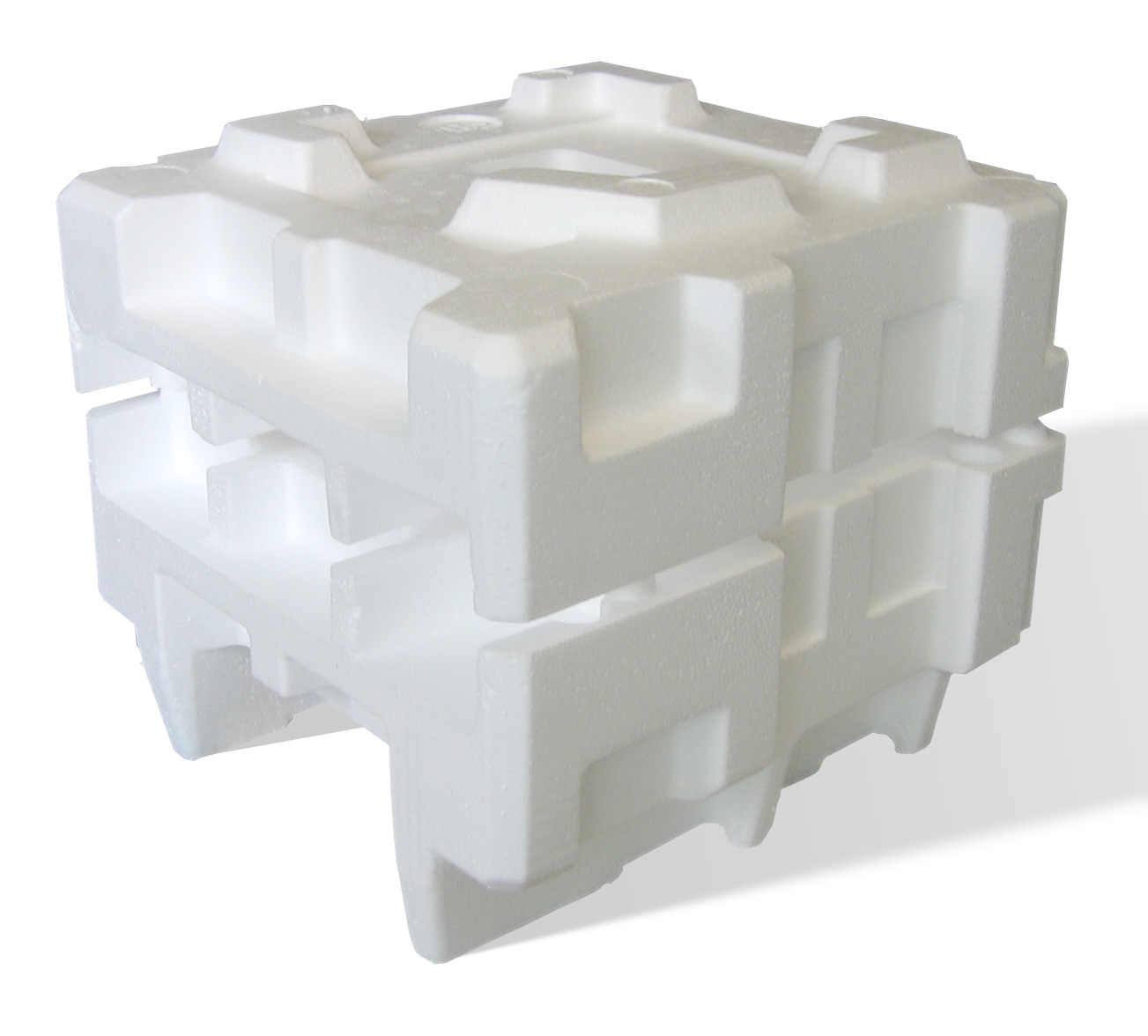

Beam And Block

Beam and block is a construction method to support flooring, especially for ground floors as well as multi story buildings. It is made of cast concrete, one piece of which is a prestressed concrete Prestressed concrete is a form of concrete used in construction. It is substantially "prestressed" ( compressed) during production, in a manner that strengthens it against tensile forces which will exist when in service. Post-tensioned concreted i ... beam, which can be an inverted T-shaped beam, or lintel, the other piece being a simple rectangular block. The beams are placed at regular intervals and the blocks placed between them. They form a support for the next layer of flooring materials. Beam and block is also referred to as rib and block or lintel and block in some countries. Certain countries incorporate the use of temporary propping for 21 days while other rib and block systems use propless systems. Systems where props are used incorporate lighter beams while the prop line all ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Underfloor Heating

Underfloor heating and cooling is a form of central heating and cooling that achieves indoor climate control for thermal comfort using hydronic or electrical heating elements embedded in a floor. Heating is achieved by conduction, radiation and convection. Use of underfloor heating dates back to the Neoglacial and Neolithic periods. History Underfloor heating has a long history back into the Neoglacial and Neolithic periods. Archeological digs in Asia and the Aleutian islands of Alaska reveal how the inhabitants drafted smoke from fires through stone covered trenches which were excavated in the floors of their subterranean dwellings. The hot smoke heated the floor stones and the heat then radiated into the living spaces. These early forms have evolved into modern systems using fluid filled pipes or electrical cables and mats. Below is a chronological overview of under floor heating from around the world. Description Modern underfloor heating systems use either electrical r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Expanded Polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a poor barrier to oxygen and water vapour and has a relatively low melting point. Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year. Polystyrene can be naturally transparent, but can be colored with colorants. Uses include protective packaging (such as packing peanuts and in the jewel cases used for storage of optical discs such as CDs and occasionally DVDs), containers, lids, bottles, trays, tumblers, disposable cutlery, in the making of models, and as an alternative material for phonograph records. As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Insulation

Thermal insulation is the reduction of heat transfer (i.e., the transfer of thermal energy between objects of differing temperature) between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with specially engineered methods or processes, as well as with suitable object shapes and materials. Heat flow is an inevitable consequence of contact between objects of different temperature. Thermal insulation provides a region of insulation in which thermal conduction is reduced, creating a thermal break or thermal barrier, or thermal radiation is reflected rather than absorbed by the lower-temperature body. The insulating capability of a material is measured as the inverse of thermal conductivity (k). Low thermal conductivity is equivalent to high insulating capability ( resistance value). In thermal engineering, other important properties of insulating materials are product density (ρ) and specific heat capacity (c). Definition T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

R-value (insulation)

In the context of construction, the R-value is a measure of how well a two-dimensional barrier, such as a layer of insulation, a window or a complete wall or ceiling, resists the conductive flow of heat. R-value is the temperature difference per unit of heat flux needed to sustain one unit of heat flux between the warmer surface and colder surface of a barrier under steady-state conditions. The ''R-value'' is the building industry term for thermal resistance "per unit area." It is sometimes denoted RSI-value if the SI units are used. An R-value can be given for a material (e.g. for polyethylene foam), or for an assembly of materials (e.g. a wall or a window). In the case of materials, it is often expressed in terms of R-value per metre. R-values are additive for layers of materials, and the higher the R-value the better the performance. The U-factor or U-value is the overall heat transfer coefficient and can be found by taking the inverse of the R-value. It is a property ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |