|

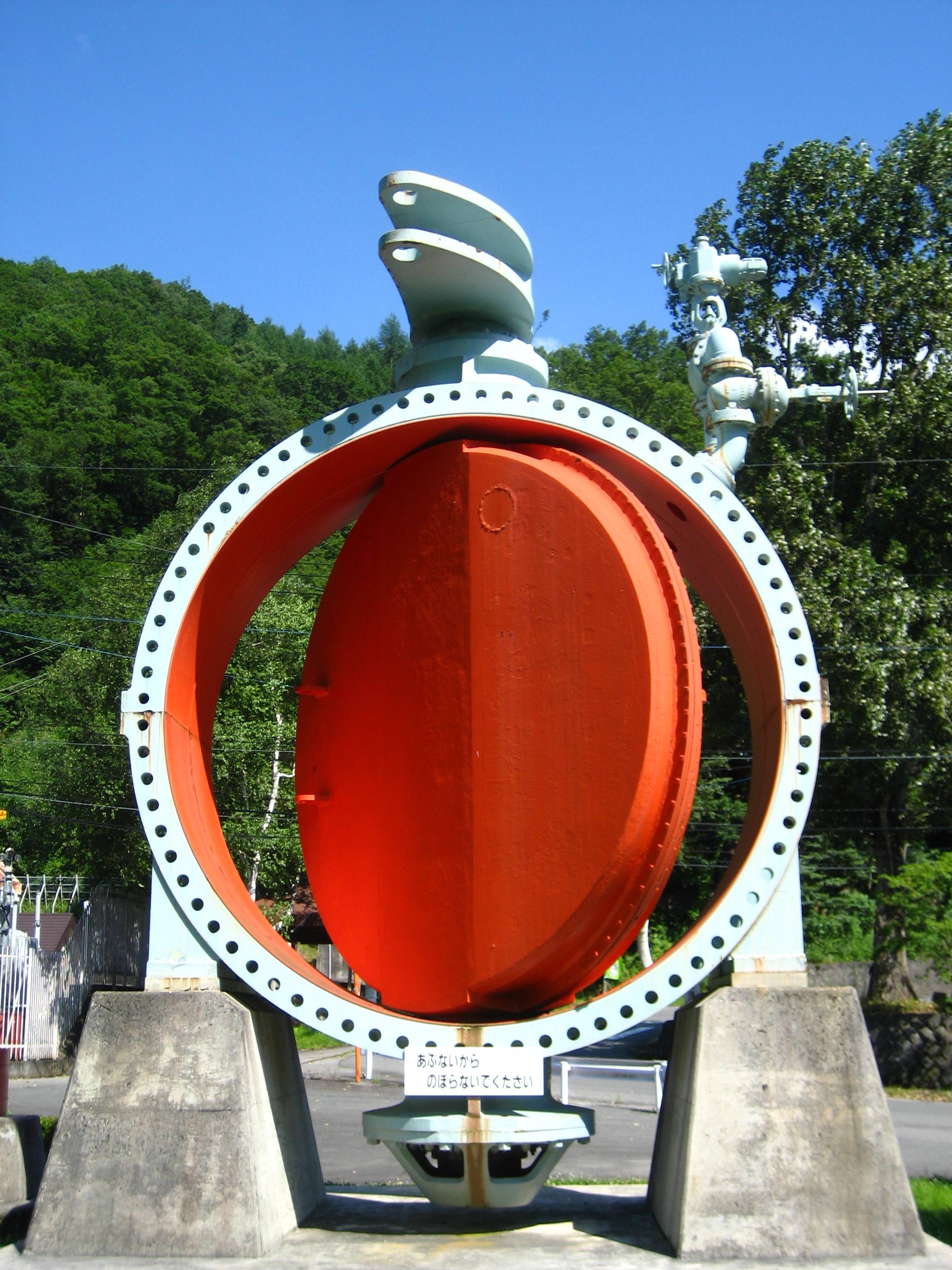

Butterfly Valve

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates. Principle of operation Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they cost less than other valve designs, and are lighter weight so they need less support. The disc is positioned in the center of the pipe. A rod passes through the disc to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, so it induces a pressure drop, even when open. A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. Wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

O-ring

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, forming a seal at the interface. The O-ring may be used in static applications or in dynamic applications where there is relative motion between the parts and the O-ring. Dynamic examples include rotating pump shafts and hydraulic cylinder pistons. Static applications of O-rings may include fluid or gas sealing applications in which: (1) the O-ring is compressed resulting in zero clearance, (2) the O-ring material is vulcanized solid such that it is impermeable to the fluid or gas, and (3) the O-ring material is resistant to degradation by the fluid or gas. The wide range of potential liquids and gases that need to be sealed has necessitated the development of a wide range of materials. O-rings are one of the most common seals used i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Pressure Pipe Systems

Plastic pipe is a tubular section, or hollow cylinder, made of plastic. It is usually, but not necessarily, of circular cross-section, used mainly to convey substances which can flow—liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipes are far stiffer per unit weight than solid members. Plastic pipework is used for the conveyance of drinking water, waste water, chemicals, heating fluid and cooling fluids, foodstuffs, ultra-pure liquids, slurries, gases, compressed air, irrigation, plastic pressure pipe systems, and vacuum system applications. Types There are three basic types of plastic pipes: Solid wall pipe Extruded pipes consisting of one layer of a homogeneous matrix of thermoplastic material which is ready for use in a pipeline. Structured wall pipe Structured-wall pipes and fittings are products which have an optimized design with regard to material usage to achieve the physical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Needle Valve

A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates. Construction and operation An instrument needle valve uses a tapered pin to gradually open a space for fine control of flow. The flow can be controlled and regulated with the use of a spindle. A needle valve has a relatively small orifice with a long, tapered seat, and a needle-shaped plunger on the end of a screw, which exactly fits the seat. As the screw is turned and the plunger retracted, flow between the seat and the plunger is possible; however, until the plunger is completely retracted, the fluid flow is significantly impeded. Since it takes many turns of the fine-threaded screw to retract the plunger, precise regulation of the flow rate is easily possible. The virtue of the needle valve is from the vernier effect of the ratio between the needle's length and its diameter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Globe Valve

A globe valve, different from ball valve, is a type of valve used for regulating flow in a pipeline, consisting of a movable plug or disc element and a stationary ring seat in a generally spherical body. Globe valves are named for their spherical body shape with the two halves of the ''body'' being separated by an internal baffle. This has an opening that forms a ''seat'' onto which a movable ''plug'' can be screwed in to close (or shut) the valve. The plug is also called a ''disc''. In globe valves, the plug is connected to a ''stem'' which is operated by screw action using a handwheel in manual valves. Typically, automated globe valves use smooth stems rather than threaded and are opened and closed by an actuator assembly. Information Although globe valves in the past had the spherical bodies which gave them their name, many modern globe valves do not have much of a spherical shape. However, the term ''globe valve'' is still often used for valves that have such an interna ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gate Valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened. The gate faces can be parallel but are most commonly wedge-shaped (in order to be able to apply pressure on the sealing surface). Typical use Gate valves are used to shut off the flow of liquids rather than for flow regulation, which is frequently done with a globe valve. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low flow resistance. The size of the open flow path generally varies in a nonlinear manner as the gate is moved. This means that the flow rate does not change evenly with stem travel. Depending on the construction, a partially open gate can vibrate from the fluid flow. Gate valves are mostly used with larger pipe diameters (from 2" to the largest pipelines) since they are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diaphragm Valve

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, an elastomeric diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve body may be constructed from plastic, metal, wood or other materials depending on the intended use. Categories There are two main categories of diaphragm valves: one type seals over a "weir" (saddle) and the other (sometimes called a "full bore or straight-through" valve) seals over a seat. In general, straight-through diaphragm valves are used in on-off applications and weir-type diaphragm valves are used for control or throttling applications. While diaphragm valves usually come in two-port forms (2/2-way diaphragm valve), they can also come with three ports (3/2-way diaphragm valves also called T-valves) and more (so called block-valves). When more than three ports are included, they generally require more than one diaphragm seat; however, special dual actuators can handle more port ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Control Valve

A control valve is a valve used to control fluid flow by varying the size of the flow passage as directed by a signal from a controller. This enables the direct control of flow rate and the consequential control of process quantities such as pressure, temperature, and liquid level. In automatic control terminology, a control valve is termed a "final control element". Operation The opening or closing of automatic control valves is usually done by electrical, hydraulic or pneumatic actuators. Normally with a modulating valve, which can be set to any position between fully open and fully closed, valve positioners are used to ensure the valve attains the desired degree of opening. Air-actuated valves are commonly used because of their simplicity, as they only require a compressed air supply, whereas electrically operated valves require additional cabling and switch gear, and hydraulically actuated valves required high pressure supply and return lines for the hydraulic fluid. The p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

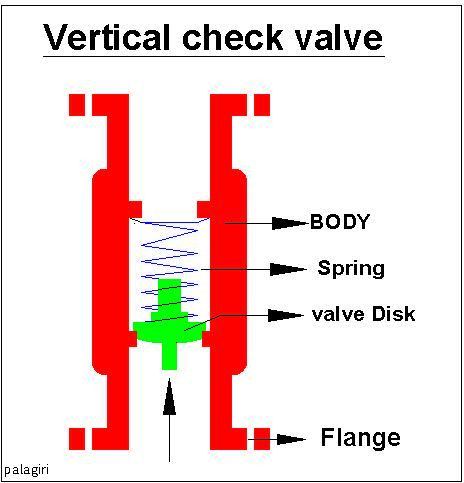

Check Valve

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, and inexpensive. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal. An important concept in check valves is the cracking pressure which is the minimum differential upstream pressure between inlet and outlet at which the valve will operate. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pigging

In pipeline transportation, pigging is the practice of using pipeline inspection gauges or gadgets, devices generally referred to as pigs or scrapers, to perform various maintenance operations. This is done without stopping the flow of the product in the pipeline. These operations include but are not limited to cleaning and inspecting the pipeline. This is accomplished by inserting the pig into a "pig launcher" (or "launching station") — an oversized section in the pipeline, reducing to the normal diameter. The launching station is then closed and the pressure-driven flow of the product in the pipeline is used to push the pig along the pipe until it reaches the receiving trap — the "pig catcher" (or "receiving station"). Applications Pigging is used to clean large diameter pipelines in the oil industry. Today, however, the use of smaller diameter pigging systems is now increasing in many continuous and batch process plants as plant operators search for increa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flange

A flange is a protruded ridge, lip or rim (wheel), rim, either external or internal, that serves to increase shear strength, strength (as the flange of an iron beam (structure), beam such as an I-beam or a T-beam); for easy attachment/transfer of contact force with another object (as the flange on the end of a pipe (fluid conveyance), pipe, steam cylinder, etc., or on the lens mount of a camera); or for stabilizing and guiding the movements of a machine or its parts (as the inside flange of a railroad car, rail car or tram train wheel, wheel, which keep the wheels from derailment, running off the rail profile, rails). Flanges are often attached using bolts in the pattern of a bolt circle. The term "flange" is also used for a kind of tool used to form flanges. Plumbing or piping A flange can also be a plate or ring to form a rim at the end of a pipe when fastened to the pipe (for example, a closet flange). A blind flange is a plate for covering or closing the end of a pipe. A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Backflow

Backflow is a term in plumbing for an unwanted flow of water in the reverse direction. It can be a serious health risk for the contamination of potable water supplies with foul water. In the most obvious case, a toilet flush cistern and its water supply must be isolated from the toilet bowl. For this reason, building codes mandate a series of measures and backflow prevention devices to prevent backflow. Causes Backflow occurs for one of two reasons, either ''back pressure'' or ''back siphonage''. ''Back pressure'' is the result of a higher pressure in the system than in its supply, i.e. the system pressure has been ''increased'' by some means. This may occur in unvented heating systems, where thermal expansion increases the pressure. ''Back siphonage'' is the result of supply pressure being ''lowered'' below that of the system. This may occur when a supply is interrupted or drained down. Risk of contamination The precise measures required to prevent backflow depend on t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |