|

Black Hills Gold Jewelry

Black Hills gold jewelry is a type of jewelry manufactured in the Black Hills of South Dakota. It was first created in the 1870s during the Black Hills Gold Rush by a French goldsmith named Henri LeBeau, who is said to have dreamed about the design after passing out from thirst and starvation. Black Hills gold jewelry depicts leaves, grape clusters and vines, and is made with alloys of gold with standard yellow gold as well as green and pink gold. In 1980, the United States Court of Appeals for the Eighth Circuit, 8th Circuit affirmed an injunction ruling that if a manufacturer was to call its jewelry Black Hills Gold, then it must be made in the Black Hills. The state of South Dakota designated Black Hills gold as the List of South Dakota state symbols, official state jewelry in 1988. The designs use grapes, grape leaves and grape stems and are easily recognizable for their distinctive colors. Silver is alloyed with the yellow gold to produce the green hue, and copper is alloyed wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

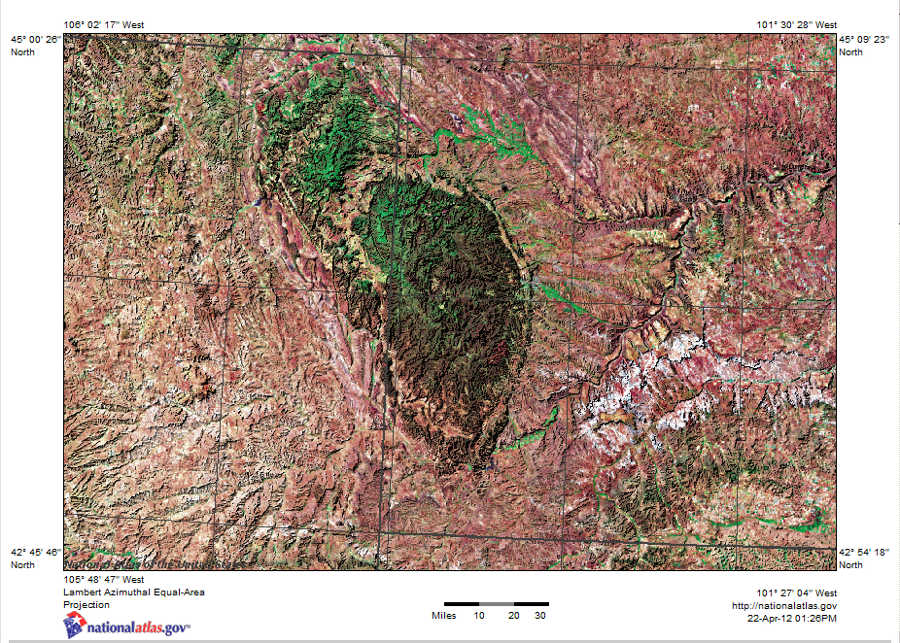

Black Hills

The Black Hills ( lkt, Ȟe Sápa; chy, Moʼȯhta-voʼhonáaeva; hid, awaxaawi shiibisha) is an isolated mountain range rising from the Great Plains of North America in western South Dakota and extending into Wyoming, United States. Black Elk Peak (formerly known as Harney Peak), which rises to , is the range's highest summit. The Black Hills encompass the Black Hills National Forest. The name of the hills in Lakota is ', meaning “the heart of everything that is." The Black Hills are considered a holy site. The hills are so called because of their dark appearance from a distance, as they are covered in evergreen trees. Native Americans have a long history in the Black Hills and consider it a sacred site. After conquering the Cheyenne in 1776, the Lakota took the territory of the Black Hills, which became central to their culture. In 1868, the U.S. government signed the Fort Laramie Treaty of 1868, establishing the Great Sioux Reservation west of the Missouri River, and exempt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carat (purity)

The fineness of a precious metal object (coin, bar, jewelry, etc.) represents the weight of ''fine metal'' therein, in proportion to the total weight which includes alloying base metals and any impurities. Alloy metals are added to increase hardness and durability of coins and jewelry, alter colors, decrease the cost per weight, or avoid the cost of high-purity refinement. For example, copper is added to the precious metal silver to make a more durable alloy for use in coins, housewares and jewelry. Coin silver, which was used for making silver coins in the past, contains 90% silver and 10% copper, by mass. Sterling silver contains 92.5% silver and 7.5% of other metals, usually copper, by mass. Various ways of expressing fineness have been used and two remain in common use: ''millesimal fineness'' expressed in units of parts per 1,000 and '' karats'' or ''carats'' used only for gold. Karats measure the parts per 24, so that 18 karat = = 75% and 24 karat gold is considered 100% g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jewelry Industry In The United States

Jewellery ( UK) or jewelry (U.S.) consists of decorative items worn for personal adornment, such as brooches, rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the clothes. From a western perspective, the term is restricted to durable ornaments, excluding flowers for example. For many centuries metal such as gold often combined with gemstones, has been the normal material for jewellery, but other materials such as glass, shells and other plant materials may be used. Jewellery is one of the oldest types of archaeological artefact – with 100,000-year-old beads made from ''Nassarius'' shells thought to be the oldest known jewellery.Study reveals 'oldest jewellery' , '' |

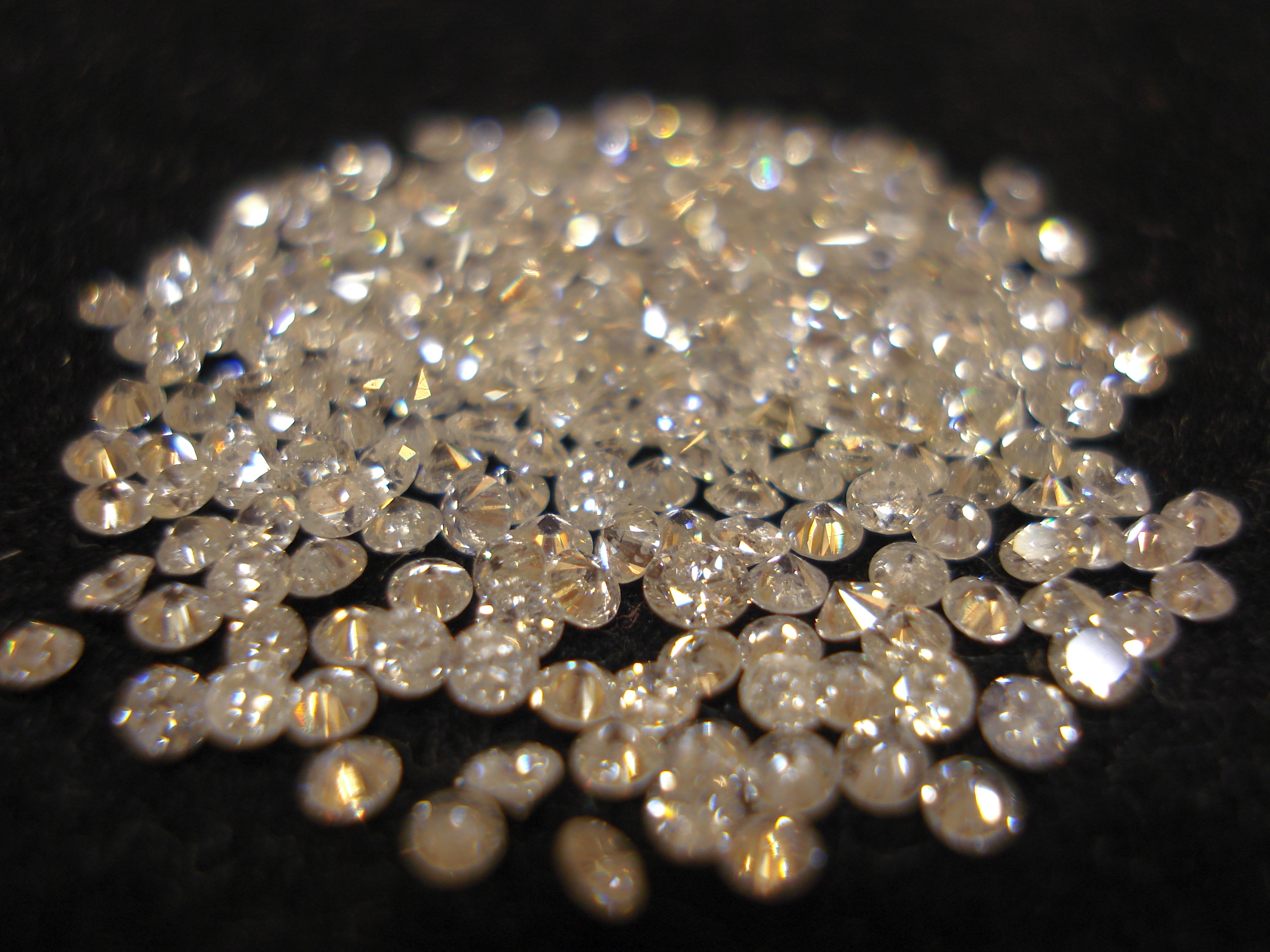

Gemstone

A gemstone (also called a fine gem, jewel, precious stone, or semiprecious stone) is a piece of mineral crystal which, in cut and polished form, is used to make jewelry or other adornments. However, certain rocks (such as lapis lazuli, opal, and obsidian) and occasionally organic materials that are not minerals (such as amber, jet, and pearl) are also used for jewelry and are therefore often considered to be gemstones as well. Most gemstones are hard, but some soft minerals are used in jewelry because of their luster or other physical properties that have aesthetic value. Rarity and notoriety are other characteristics that lend value to gemstones. Apart from jewelry, from earliest antiquity engraved gems and hardstone carvings, such as cups, were major luxury art forms. A gem expert is a gemologist, a gem maker is called a lapidarist or gemcutter; a diamond cutter is called a diamantaire. Characteristics and classification The traditional classification in the West, wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lustre (mineralogy)

Lustre (British English) or luster (American English; see spelling differences) is the way light interacts with the surface of a crystal, rock, or mineral. The word traces its origins back to the Latin ''lux'', meaning "light", and generally implies radiance, gloss, or brilliance. A range of terms are used to describe lustre, such as ''earthy'', ''metallic'', ''greasy'', and ''silky''. Similarly, the term ''vitreous'' (derived from the Latin for glass, ''vitrum'') refers to a glassy lustre. A list of these terms is given below. Lustre varies over a wide continuum, and so there are no rigid boundaries between the different types of lustre. (For this reason, different sources can often describe the same mineral differently. This ambiguity is further complicated by lustre's ability to vary widely within a particular mineral species). The terms are frequently combined to describe intermediate types of lustre (for example, a "vitreous greasy" lustre). Some minerals exhibit unus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engraving

Engraving is the practice of incising a design onto a hard, usually flat surface by cutting grooves into it with a Burin (engraving), burin. The result may be a decorated object in itself, as when silver, gold, steel, or Glass engraving, glass are engraved, or may provide an Intaglio (printmaking), intaglio printing plate, of copper or another metal, for printing images on paper as prints or illustrations; these images are also called "engravings". Engraving is one of the oldest and most important techniques in printmaking. Wood engraving is a form of relief printing and is not covered in this article, same with rock engravings like petroglyphs. Engraving was a historically important method of producing images on paper in artistic printmaking, in mapmaking, and also for commercial reproductions and illustrations for books and magazines. It has long been replaced by various photographic processes in its commercial applications and, partly because of the difficulty of learning th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soldering

Soldering (; ) is a process in which two or more items are joined by melting and putting a filler metal (solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not involve melting the work pieces. In brazing, the work piece metal also does not melt, but the filler metal is one that melts at a higher temperature than in soldering. In the past, nearly all solders contained lead, but environmental and health concerns have increasingly dictated use of lead-free alloys for electronics and plumbing purposes. Origins There is evidence that soldering was employed as early as 5,000 years ago in Mesopotamia. Soldering and brazing are thought to have originated very early in the history of metal-working, probably before 4000 BC. Sumerian swords from were assembled using hard soldering. Soldering was historically used to make jewelry, cookware and cooking tools, assembling stained glass, as well as other uses. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tumble Finishing

Tumble finishing, also known as tumbling or rumbling, is a technique for smoothing and polishing a rough surface on relatively small parts. In the field of metalworking, a similar process called barreling, or barrel finishing,Degarmo, p. 781. works upon the same principles. Tumbled stones are made with rock tumblers in a process very similar to the natural processes that produce "sea glass" or "beach glass". Stones Tumbling of rocks as a lapidary technique for rock polishing usually requires a plastic or rubber-lined barrel loaded with a consignment of rocks, all of similar or the same hardness, some abrasive grit, and a liquid lubricant. Silicon carbide grit is commonly used, and water is a universal lubricant. The barrel is then placed upon slowly rotating rails so that it rotates. The optimal speed of rotation depends on the size of the tumbler barrel and materials involved. Vibratory finishing process can be used instead. A well-chosen speed for stone polishing causes th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polishing (metalworking)

Polishing and buffing are finishing processes for smoothing a workpiece's surface using an abrasive and a work wheel or a leather strop. Technically, ''polishing'' refers to processes that uses an abrasive that is glued to the work wheel, while ''buffing'' uses a loose abrasive applied to the work wheel. Polishing is a more aggressive process, while buffing is less harsh, which leads to a smoother, brighter finish.Oberg, p. 1439. A common misconception is that a polished surface has a mirror-bright finish, however, most mirror-bright finishes are actually buffed. Polishing is often used to enhance the appearance of an item, prevent contamination of instruments, remove oxidation, create a reflective surface, or prevent corrosion in pipes. In metallography and metallurgy, polishing is used to create a flat, defect-free surface for examination of a metal's microstructure under a microscope. Silicon-based polishing pads or a diamond solution can be used in the polishing process. Po ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting (metalworking)

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold (usually by a crucible) that contains a negative impression (i.e., a three-dimensional negative image) of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part (the ''casting'') is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods. Casting processes have been known for thousands of years, and have been widely used for sculpture (especially in bronze), jewelry in precious metals, and weapons and tools. Highly engineered castings are found in 90 percent of durable goods, including cars, trucks, aerospace, trains, mining and construction equipment, oil wells, appliances, pipes, hydrants, wind turbines, nuclear plants, medical devices, defense products, toys, and more. Traditional techniques include lost ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (manufacturing)

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies (used in the manufacture of wire) and casting dies (used in molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two die cutting operations, and bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force (compression, tension, or both) and rely on the material's mechanical properties. Forming dies are typically made by tool and die makers and put into production after mounting into a press. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stamping (metalworking)

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined. Stamping is usually ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |