|

BS 4994

BS4994 (formally: British Standard 4994:1987) is the "specification for the design and construction of vessels and storage tanks in reinforced plastics". It specifies a code of practice for use by manufacturers of such containers. With the publication of BS EN 13121-3, BS 4994:1987 Specification for design and construction of vessels and tanks in reinforced plastics is declared obsolescent, which will still cover those tanks still in service as tanks made from GRP are generally accepted to have a long working life. Dual laminate construction, simple FRP with glass mats, or a combination of unidirectional filament winding are common. DUAL LAMINATE : A thermoplastic lining material, preferably 3mm to 5mm thick sheet functions as a corrosion barrier. This thermoplastic liner is not considered to contribute mechanical strength. FRP which is constructed over this lining provides the strength requirements for materials to withstand design conditions like pressure, vacuum, hydrostatic loa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

British Standard

British Standards (BS) are the standards produced by the BSI Group which is incorporated under a royal charter and which is formally designated as the national standards body (NSB) for the UK. The BSI Group produces British Standards under the authority of the charter, which lays down as one of the BSI's objectives to: Formally, as stated in a 2002 memorandum of understanding between the BSI and the United Kingdom Government, British Standards are defined as: Products and services which BSI certifies as having met the requirements of specific standards within designated schemes are awarded the Kitemark. History BSI Group began in 1901 as the ''Engineering Standards Committee'', led by James Mansergh, to standardize the number and type of steel sections, in order to make British manufacturers more efficient and competitive. Over time the standards developed to cover many aspects of tangible engineering, and then engineering methodologies including quality systems, safety ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Storage Tank

Storage tanks are containers that hold liquids, compressed gases (gas tank; or in U.S.A "pressure vessel", which is not typically labeled or regulated as a storage tank) or mediums used for the short- or long-term storage of heat or cold. The term can be used for reservoirs (artificial lakes and ponds), and for manufactured containers. The usage of the word tank for reservoirs is uncommon in American English but is moderately common in British English. In other countries, the term tends to refer only to artificial containers. In the USA, storage tanks operate under no (or very little) pressure, distinguishing them from ''pressure vessels''. Storage tanks are often cylindrical in shape, perpendicular to the ground with flat bottoms, and a fixed frangible or floating roof. There are usually many environmental regulations applied to the design and operation of storage tanks, often depending on the nature of the fluid contained within. Above-ground storage tanks (ASTs) differ from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reinforced Plastic

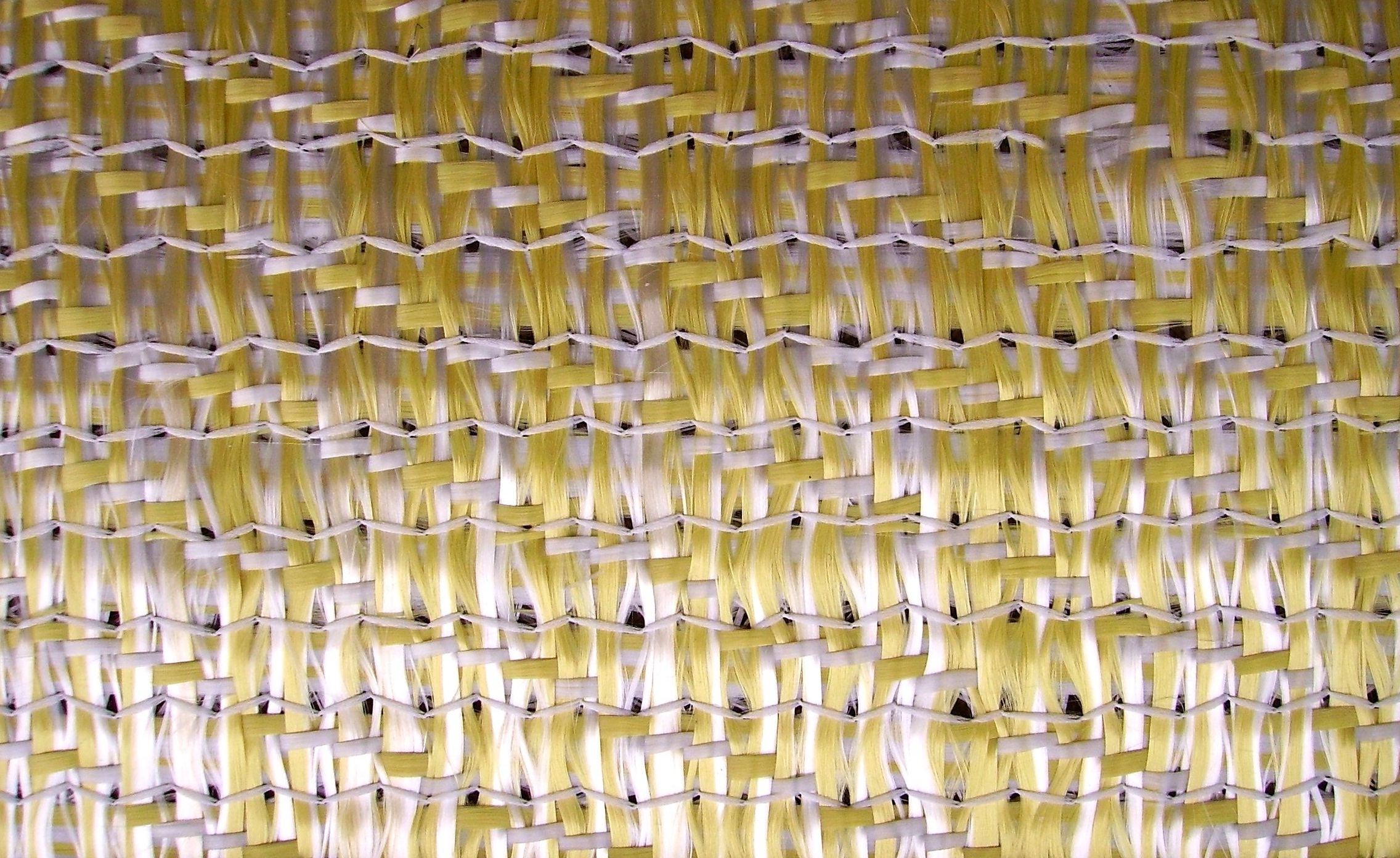

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. Process definition A polymer is generally manufactured by step-growth polymerization or addition polymerization. When combined with various agents to enhance or in any way alter the material properties of polymers, the result is referred to as a plastic. Composite plastics refers to those types of plastics tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers (or "thermosets"), which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling. Above its glass transition temperature and below its melting point, the physical properties of a thermoplastic change drastically without an associated phase change. Some thermoplastics do not fully crystal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Bio-PP is the bio-based counterpart of polypropylene (PP). Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion. Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021. History Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerizat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PTFE

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. It is one of the best-known and widely applied PFAS. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a spin-off from DuPont, which originally discovered the compound in 1938. Polytetrafluoroethylene is a fluorocarbon solid, as it is a high- molecular-weight polymer consisting wholly of carbon and fluorine. PTFE is hydrophobic: neither water nor water-containing substances wet PTFE, as fluorocarbons exhibit only small London dispersion forces due to the low electric polarizability of fluorine. PTFE has one of the lowest coefficients of friction of any solid. Polytetrafluoroethylene is used as a non-stick coating for pans and other cookware. It is non-reactive, partly because of the strength of carbon–fluorine bonds, so it is often used in containers and pipework for reactive and corrosive chemicals. Where used as a lubrican ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ECTFE

ECTFE (ethylenechlorotrifluoroethylene) is a copolymer of ethylene and chlorotrifluoroethylene. It is a semi-crystalline fluoropolymer (a partially fluorinated polymer) designed to provide chemical resistance in heavy-duty corrosion applications. Physical and chemical properties ECTFE is resistant to acids at high concentrations and temperatures, caustic media, oxidizing agents and many solvents. It is said to have similar chemical resistance to PTFE. A chemical resistance table, based on immersion tests, has explored this further. Permeation of large molecules is slow in fluoropolymers and thus is not relevant in the final application. Small molecules, however, may permeate through the polymer matrix at a relevant time. In lining or coating applications, the permeation of certain small molecules determines the lifetime of anti-corrosion protection. H2O, O2, Cl2, H2S, HCl, HF, HBr, N2, H2, CH3OH, etc. are relatively mobile in a polymer matrix and lead to measurable ef ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CPVC

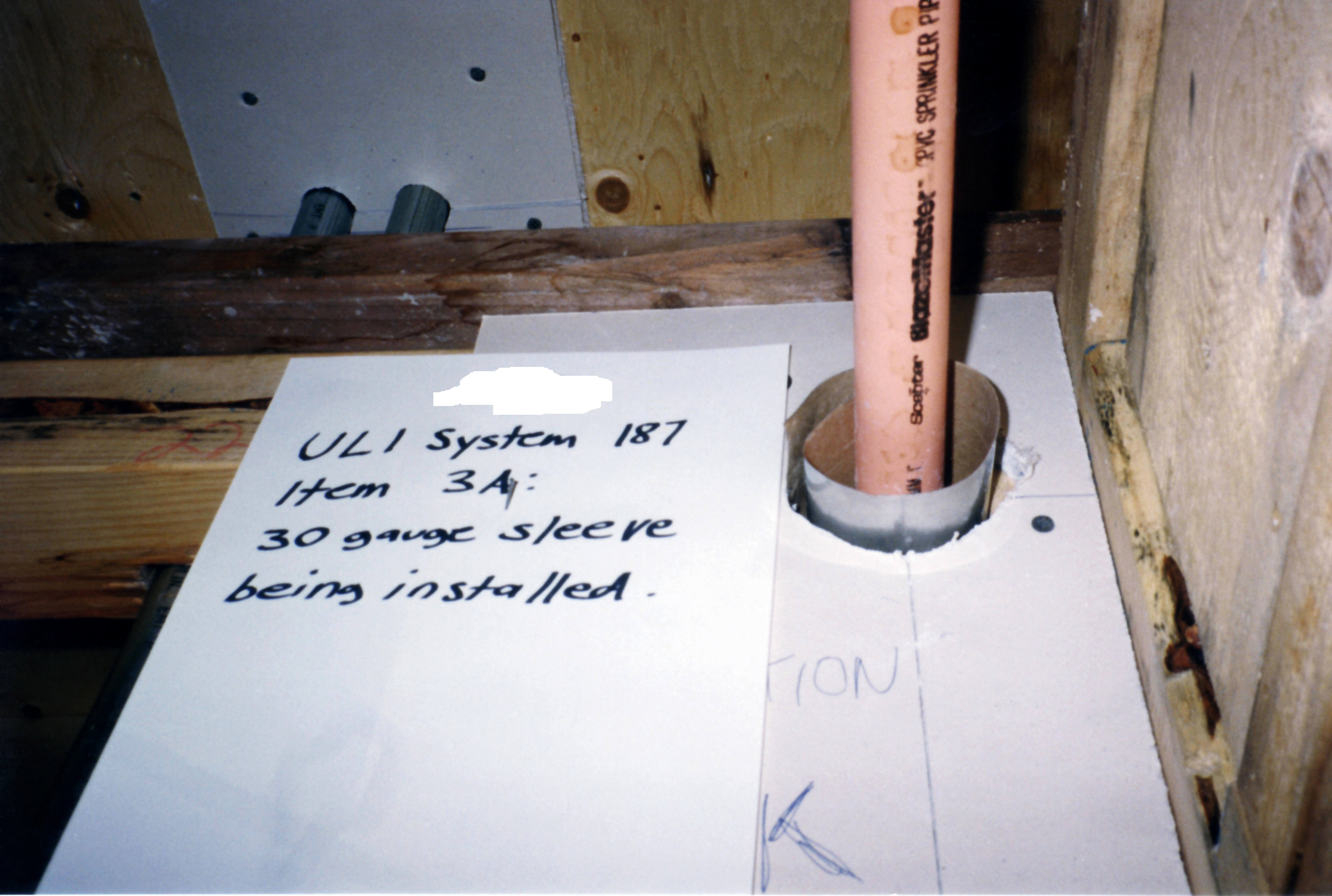

Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin. CPVC is significantly more flexible than PVC, and can also withstand higher temperatures. Uses include hot and cold water delivery pipes and industrial liquid handling. CPVC, like PVC, is deemed safe for the transport and use of potable water. History Genova Products located in Michigan initially created the first CPVC tubing and fittings for hot- and cold-water distribution systems in the early 1960s. The original tetrahydrofuran (THF) / methyl ethyl ketone (MEK) formulas for CPVC cements were developed by Genova in conjunction with the B.F. Goodrich Company, the original developer of the CPVC resin. Production process Chlorinated polyvinyl chloride (CPVC) is PVC that has been chlorinated via a free radical chlorination reaction. This reaction is typically initiated by application of thermal or UV energy utilizing various approaches. In the process, chlorine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PVDF

Polyvinylidene fluoride or polyvinylidene difluoride (PVDF) is a highly non-reactive thermoplastic fluoropolymer produced by the polymerization of vinylidene difluoride. PVDF is a specialty plastic used in applications requiring the highest purity, as well as resistance to solvents, acids and hydrocarbons. PVDF has low density 1.78 g/cm3 in comparison to other fluoropolymers, like polytetrafluoroethylene. It is available in the form of piping products, sheet, tubing, films, plate and an insulator for premium wire. It can be injected, molded or welded and is commonly used in the chemical, semiconductor, medical and defense industries, as well as in lithium-ion batteries. It is also available as a cross-linked closed-cell foam, used increasingly in aviation and aerospace applications, and as an exotic 3D printer filament. It can also be used in repeated contact with food products, as it is FDA-compliant and non-toxic below its degradation temperature. As a fine powder gra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

FRP Tanks And Vessels

FRP ( Fibreglass Reinforced Plastics, also known as GRP, or Glass Reinforced Plastics) is a modern composite material of construction for chemical plant equipment like tanks and vessels. Chemical equipment that range in size from less than a metre to 20 metres are fabricated using FRP as material of construction. FRP Chemical Equipments are manufactured mainly by Hand Lay-up and filament winding processes. BS4994 still remains a key standard for this class of items. Dual Laminate Due to the corrosion resistant nature of FRP, the tank can be made entirely from the composite, or a second liner can be used. In either case, the inner liner is made using different material properties than the structural portion (Hence the name dual (meaning two) and laminate (a word commonly used for a layer of a composite material)) The liner, if made of FRP is usually resin rich and utilizes a different type of glass, called "C-Glass", while the structural portion uses "E-Glass". The thermoplasti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |