|

BSA B25

The BSA B25 was a series of unit construction single-cylinder OHV four-stroke motorcycles made by the Birmingham Small Arms Company. Developed from the BSA C15 The BSA C15 was a 250 cc single-cylinder ohv motorcycle manufactured by the British company BSA from September 1958 until 1967, and was BSA's first four-stroke unit-construction bike. For most of that period, after the introduction of 'L ..., the machines were produced between 1967 and 1971. The B25 was the fastest British production 250. Technical details The 247 cc engine was a higher performance development of that used the existing C15. Bore (engine), Bore and Stroke (engine), stroke of 67 x 70 mm was retained, but a new alloy Cylinder (engine), barrel and cylinder head were introduced featuring square fins. The pushrod tunnel was cast into the barrel rather than being a separate item as on earlier models. Tappet adjustment was by eccentric Rocker arm, rocker shaft. To improve performance the inlet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

BSA Motorcycles

BSA motorcycles were made by the Birmingham Small Arms Company Limited (BSA), which was a major British industrial combine, a group of businesses manufacturing military and sporting firearms; bicycles; motorcycles; cars; buses and bodies; steel; iron castings; hand, power, and machine tools; coal cleaning and handling plants; sintered metals; and hard chrome process. A government-organised rescue operation in 1973 led to the takeover of BSA-Triumph motorcycle operations by Norton-Villiers, later known as Norton Villiers Triumph. At its peak, BSA (including Triumph) was the largest motorcycle producer in the world. In the late 1950s and early 1960s poor management and failure to develop new products in the motorcycle division led to a dramatic decline of sales to its major USA market. The management had failed to appreciate the importance of the resurgent Japanese motorcycle industry, leading to problems for the entire BSA group. When Norton Villiers Triumph was liquidated in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Birmingham Small Arms Company

The Birmingham Small Arms Company Limited (BSA) was a major British industrial combine, a group of businesses manufacturing military and sporting firearms; bicycles; motorcycles; cars; buses and bodies; steel; iron castings; hand tool, hand, power tool, power, and machine tool, machine tools; coal cleaning and handling plants; sintered metals; and hard chrome process. After the Second World War, BSA did not manage its business well, and a government-organised rescue operation in 1973 led to a takeover of such operations as it still owned. Those few that survived this process disappeared into the ownership of other businesses. History of the BSA industrial group Machine-made guns BSA began in June 1861 in the Gun Quarter, Birmingham, England. It was formed by a group of fourteen gunsmith members of the Birmingham Small Arms Trade Association specifically to manufacture guns by machinery. They were encouraged to do this by the War Office which gave the BSA gunsmiths free access ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conrod

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end. The predecessor to the connecting rod is a mechanic linkage used by water mills to convert rotating motion of the water wheel into reciprocating motion. The most common usage of connecting rods is in internal combustion engines or on steam engines. __TOC__ Origins The predecessor to the connecting length is the mechanical linkage used by Roman-era watermills. The earliest known example of this linkage has been found at the late 3rd century Hierapolis sawmill in Roman Asia (modern Turkey) and the 6th century s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Big End

Big or BIG may refer to: * Big, of great size or degree Film and television * ''Big'' (film), a 1988 fantasy-comedy film starring Tom Hanks * '' Big!'', a Discovery Channel television show * ''Richard Hammond's Big'', a television show presented by Richard Hammond * ''Big'' (TV series), a 2012 South Korean TV series * '' Banana Island Ghost'', a 2017 fantasy action comedy film Music * '' Big: the musical'', a 1996 musical based on the film * Big Records, a record label * ''Big'' (album), a 2007 album by Macy Gray * "Big" (Dead Letter Circus song) * "Big" (Sneaky Sound System song) * "Big" (Rita Ora and Imanbek song) * "Big", a 1990 song by New Fast Automatic Daffodils * "Big", a 2021 song by Jade Eagleson from '' Honkytonk Revival'' *The Notorious B.I.G., an American rapper Places * Allen Army Airfield (IATA code), Alaska, US * BIG, a VOR navigational beacon at London Biggin Hill Airport * Big River (other), various rivers (and other things) * Big Island (disambi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roller Bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls on to it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See " bearings" for more on the historical development of bearings. A rolling element rotary bearing uses a shaft in a much larger hole, and cylinders called "rollers" tightly fill the space between t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams, in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han Dynasty in China, and they were widespread by the medieval period. The camshaft was described in 1206 by engineer Al-Jazari. He employed it as part of his automata, water-raising machines, and water clocks such as the castle clock. Once the rotative version of the steam engine was developed in the late 18th century, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

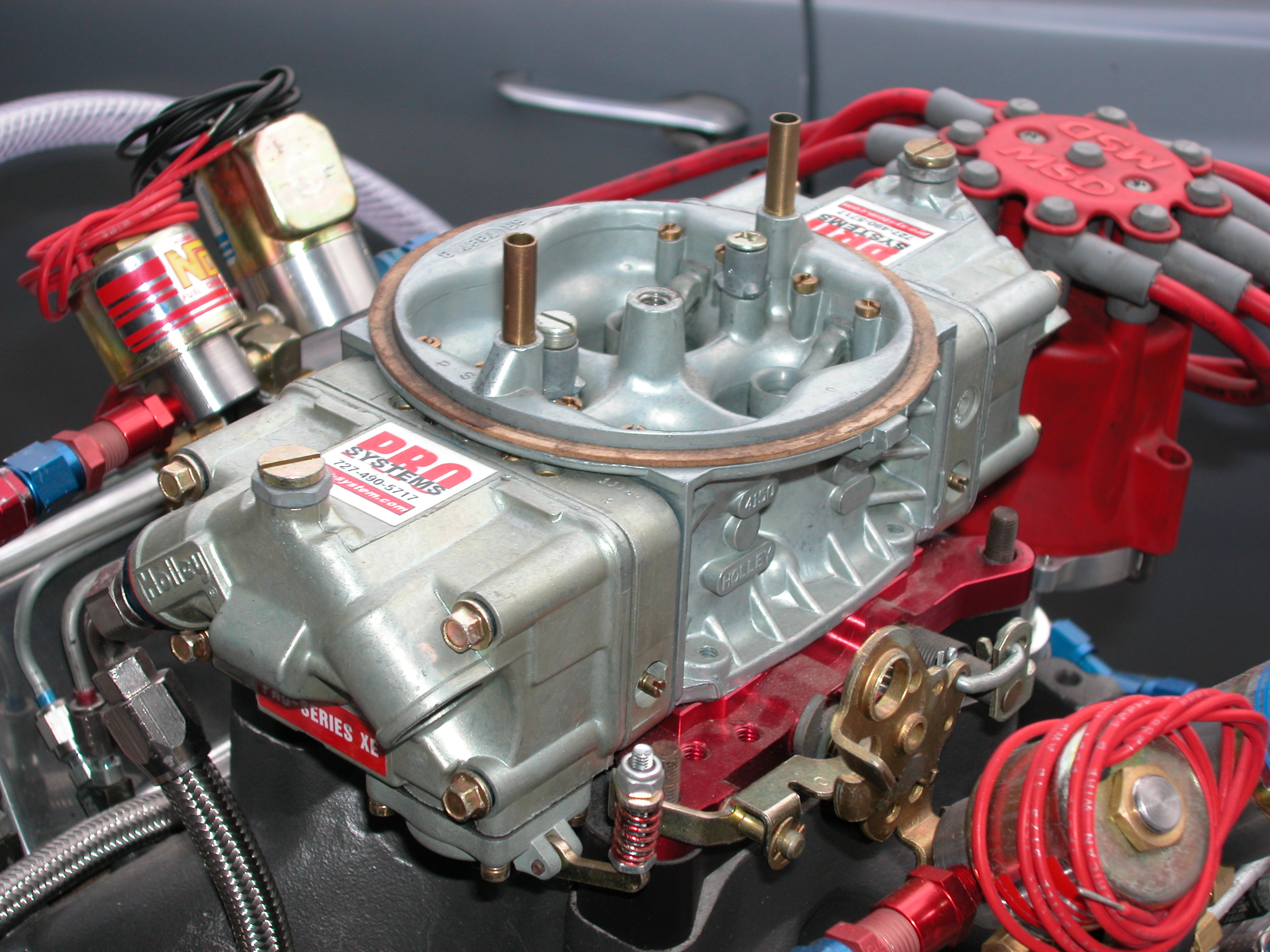

Carburettor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main metering circuit, however various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, however carburetors are still used by some small engines (e.g. lawnmowers, generators and concrete mixers) and motorcycles. Diesel engines have always used fuel injection instead of carburetors. Etymology The name "carburetor" is derived from the verb ''carburet'', which means "to combine with carbon," or in particular, "to enrich a gas by combining it with carbon or hydrocarbons." Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG). The name is spelled "carburetor" in American English a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

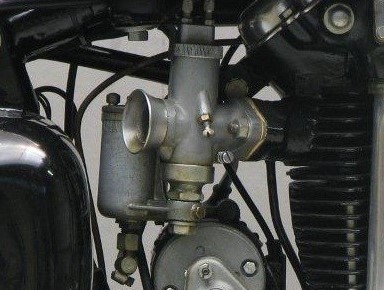

Amal Concentric

AMAL was a British engineering company servicing the motorcycle and other light-engineering motor industries between 1927 and 1993Amalgamated Carburetters Grace's Industrial Guide. Retrieved 2013-07-09 based in . AMAL is a British trademark. Amal was the supplier of carburettors to many marques within the British motorcycle industry including the largest of British manufacturers, such as [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rocker Arm

In the context of an internal combustion engine, a rocker arm is a valvetrain component that typically transfers the motion of a pushrod to the corresponding intake/exhaust valve. Rocker arms in automobiles are typically made from stamped steel, or aluminum in higher-revving applications. Some rocker arms (called ''roller rockers'') include a bearing at the contact point, to reduce wear and friction at the contact point. Overview In the typical use-case of an overhead valve (pushrod) engine, the camshaft at the bottom of the engine pushes the pushrod upwards. The top of the pushrod presses upwards on one side of the rocker arm (located at the top of the engine), which causes the rocker arm to rotate. This rotation causes the other end of the rocker arm to press downwards on the top of the valve, which opens the valve by moving it downwards. A ''roller rocker'' is a rocker arm that uses needle bearings (or a single bearing ball in older engines) at the contact point between the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tappet

A tappet is most commonly a component in an internal combustion engine which converts the rotating motion of the camshaft into linear motion of the valves, either directly or indirectly. An earlier use of the term was for part of the valve gear in beam engines beginning in 1715. The term is also used for components in pneumatic cylinders and weaving loom. __TOC__ Beam engines The first recorded use of the term tappet is as part of the valve gear in the 1715 Newcomen engine, an early form of steam engine. Early versions of the Newcomen engines from 1712 had manually operated valves, but by 1715 this repetitive task had been automated through the use of tappets. The beam of the engine had a vertical 'plug rod' hung from it, alongside the cylinder. Adjustable blocks or 'tappets' were attached to this rod and as the beam moved up and down, the tappets pressed against long levers or 'horns' attached to the engine's valves, working the cycle of steam and injection water valves ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pushrod

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: * Flathead engine: The camshaft and the valves are located in the engine block below the combustion chamber. * Overhead valve engine: The camshaft remains in the block, however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: The valves and camshaft(s) are in the cylinder head above the combustion chamber. Components The valvetrain consists of all the compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinders and forms the roof of the combustion chamber. In sidevalve engines, the head is a simple sheet of metal; whereas in more modern overhead valve and overhead camshaft engines, the cylinder head is a more complicated block often containing inlet and exhaust passages, coolant passages, valves, camshafts, spark plugs and fuel injectors. Most straight engines have a single cylinder head shared by all of the cylinders and most V engines have two cylinder heads (one per bank of cylinders). Design A summary of engine designs is shown below, in chronological order for automobile usage. Sidevalve engines In a flathead (''sidevalve'') engine, all of the valvetrain components are contained within the block, therefore the head is usually a simple sheet of metal bolted to the top of the engine block. Sidevalve engines were once universal in automobiles but are now lar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_-_29843848861.jpg)