|

Batch Production

Batch production is a method of manufacturing where the products are made as specified groups or amounts, within a time frame. A batch can go through a series of steps in a large manufacturing process to make the final desired product. Batch production is used for many types of manufacturing that may need smaller amounts of production at a time to ensure specific quality standards or changes in the process. This is opposed to large mass production or continuous production methods where the product or process does not need to be checked or changed as frequently or periodically. Characteristics In the manufacturing batch production process, the machines are in chronological order directly related to the manufacturing process. The batch production method is also used so any temporary changes or modifications can be made to the product if necessary during the manufacturing process. For example, if a product needed a sudden change in material or details changed, it can be done in be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mass Production

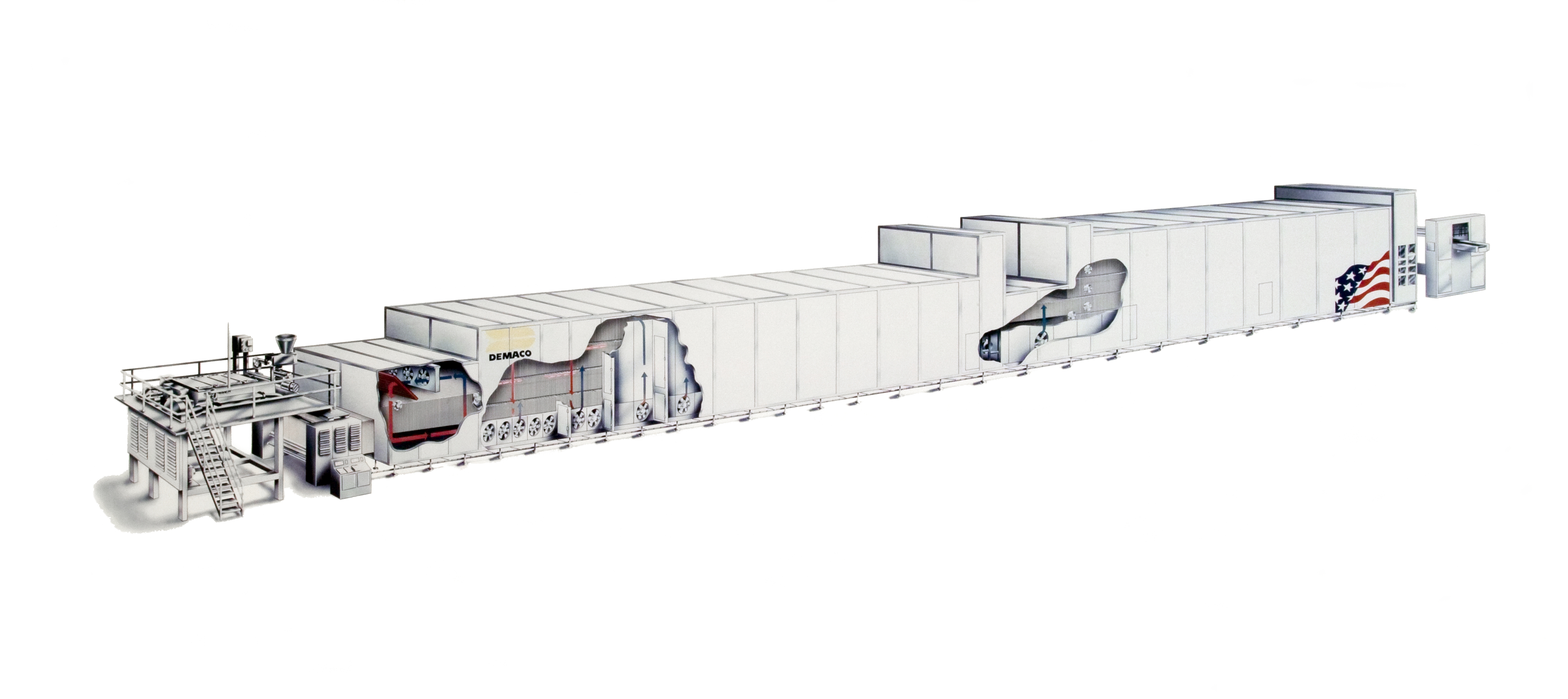

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch production, it is one of the three main production methods. The term ''mass production'' was popularized by a 1926 article in the ''Encyclopædia Britannica'' supplement that was written based on correspondence with Ford Motor Company. ''The New York Times'' used the term in the title of an article that appeared before publication of the ''Britannica'' article. The concepts of mass production are applied to various kinds of products: from fluids and particulates handled in bulk (food, fuel, chemicals and mined minerals), to parts and assemblies of parts (household appliances and automobiles). Some mass production techniques, such as standardized sizes and production lines, predate the Industrial Revolution by many centuries; however, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continuous Production

Continuous production is a flow production method used to manufacture, produce, or process materials without interruption. Continuous production is called a continuous process or a continuous flow process because the materials, either dry bulk or fluids that are being processed are continuously in motion, undergoing chemical reactions or subject to mechanical or heat treatment. Continuous processing is contrasted with batch production. Continuous usually means operating 24 hours per day, seven days per week with infrequent maintenance shutdowns, such as semi-annual or annual. Some chemical plants can operate for more than one to two years without a shutdown. Blast furnaces can run from four to ten years without stopping. Common processes Some common continuous processes are the following: * Oil refining *Chemicals *Synthetic fibers *Fertilizers *Pulp and paper *Blast furnace (iron) *Metal smelting *Power stations *Natural gas processing *Sanitary waste water treatment *Con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lot Number

A lot number is an identification number assigned to a particular quantity or lot of material from a single manufacturer. Lot numbers can typically be found on the outside of packaging. For cars, a lot number is combined with a serial number to form the Vehicle Identification Number. The lot number enables tracing of the constituent parts or ingredients as well as labor and equipment records involved in the manufacturing of a product. This enables manufacturers and other entities to perform quality control checks, calculate expiration dates, and issue corrections or recall information to subsets of their production output. It also gives consumers an identifier that they can use in contacting the manufacturer and researching the production of goods received. For example to trace back the origin of fish or meat, in case of a public health problem. Some lot numbers are generated with the use of date and time stamps to help identify a specific lot. See also *Batch production *Heat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ativan Blister Packs

Lorazepam, sold under the brand name Ativan among others, is a benzodiazepine medication. It is used to treat anxiety disorders, trouble sleeping, severe agitation, active seizures including status epilepticus, alcohol withdrawal, and chemotherapy-induced nausea and vomiting. It is also used during surgery to interfere with memory formation and to sedate those who are being mechanically ventilated. It is also used, along with other treatments, for acute coronary syndrome due to cocaine use. It can be given by mouth or as an injection into a muscle or vein. When given by injection onset of effects is between one and thirty minutes and effects last for up to a day. Common side effects include weakness, sleepiness, low blood pressure, and a decreased effort to breathe. When given intravenously the person should be closely monitored. Among those who are depressed there may be an increased risk of suicide. With long-term use, larger doses may be required for the same effect. P ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lot Number

A lot number is an identification number assigned to a particular quantity or lot of material from a single manufacturer. Lot numbers can typically be found on the outside of packaging. For cars, a lot number is combined with a serial number to form the Vehicle Identification Number. The lot number enables tracing of the constituent parts or ingredients as well as labor and equipment records involved in the manufacturing of a product. This enables manufacturers and other entities to perform quality control checks, calculate expiration dates, and issue corrections or recall information to subsets of their production output. It also gives consumers an identifier that they can use in contacting the manufacturer and researching the production of goods received. For example to trace back the origin of fish or meat, in case of a public health problem. Some lot numbers are generated with the use of date and time stamps to help identify a specific lot. See also *Batch production *Heat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |