|

BSA Unit Twins

The BSA unit twins were a range of unit construction twin-cylinder motorcycles made by the Birmingham Small Arms Company (BSA) and aimed at the US market. A range of , and twins were produced between 1962 and 1972, but they were really developments of the older pre-unit A7/A10 model range with less weight. The engines had a reputation for vibration, but acceleration was good for the time, to a top speed of . Models for the US generally had smaller petrol tanks and higher wider handlebars than the UK models, and prior to 1966 different model names were used for the two markets. The 500cc models were discontinued in 1971 when the single cylinder B50 model was introduced. The BSA Group faced worsening financial difficulties and in 1973 merged with Norton-Villiers. As part of a rationalisation by the newly formed Norton Villiers Triumph, production of BSA motorcycles ceased. Design Background Precipitated by Lucas's intent to discontinue magnetos and dynamos in favour of alt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

BSA A65 Rocket

The BSA A65R Rocket was one of a series of unit construction twin cylinder Birmingham Small Arms Company (BSA) motorcycles made in the 1960s. A version branded as the A65 'Thunderbolt Rocket' was aimed at the US market. The A65R Rocket was produced from 1964 but was stopped in 1965 when all development at BSA was halted by financial difficulties. Development The A65R was a development of the old model range led by Bob Fearon, Managing Director and General Manager of BSA and Chief Development Engineer Bert Perrigo they developed the unit construction ''Star twins''. To make the A65R more of a 'sports version' of the original BSA A65 Star (and in anticipation of more stringent noise control legislation) it was given 'siamesed' 2 into 1 exhaust pipes with a special baffle, as well as chrome plated mudguards and headlight brackets. Able to cruise at 85 mph (137 km/h) and with a top speed of 108 mph (174 km/h) it was sold as the fastest BSA in production. A special versi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

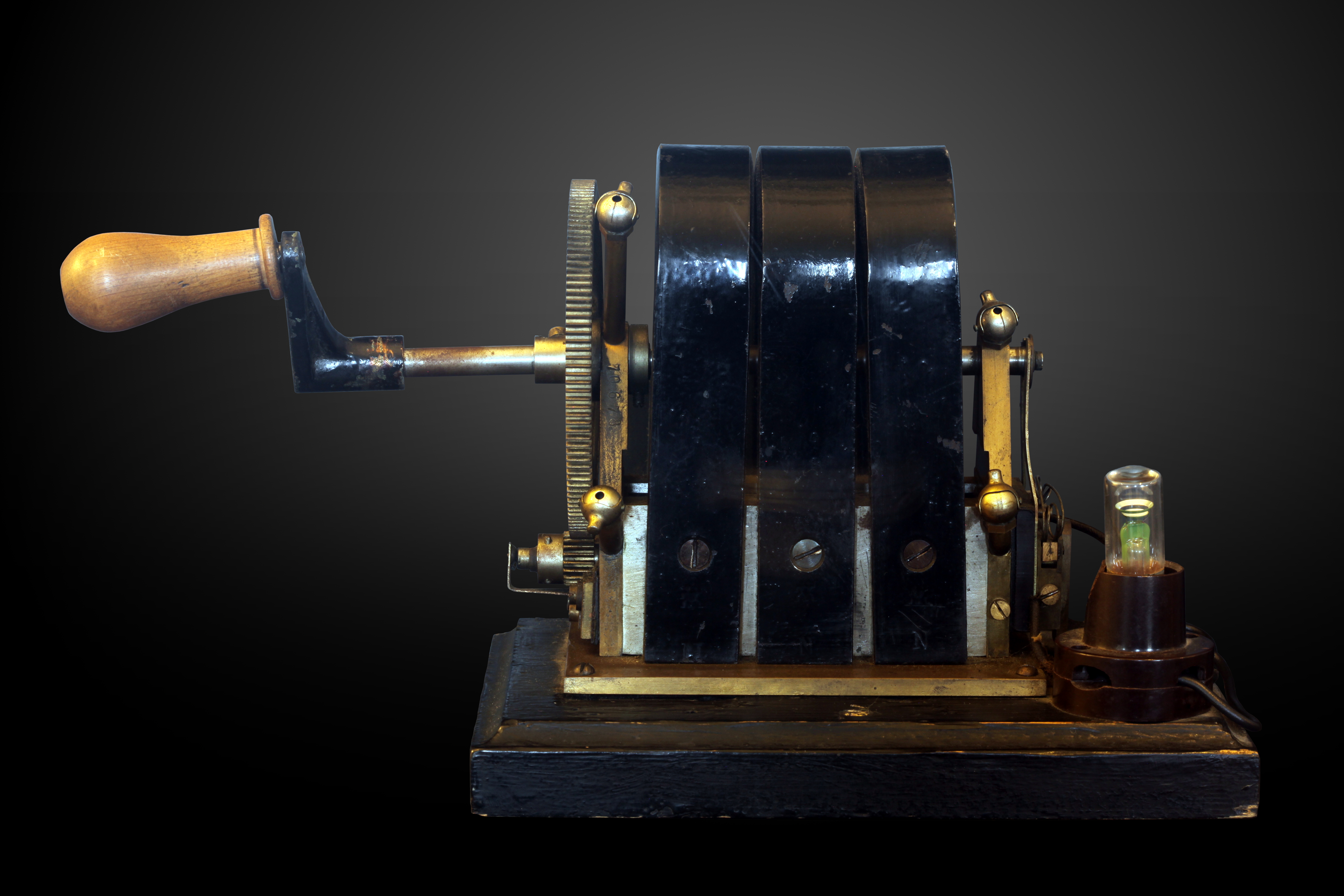

Magneto

A magneto is an electrical generator that uses permanent magnets to produce periodic pulses of alternating current. Unlike a dynamo, a magneto does not contain a commutator to produce direct current. It is categorized as a form of alternator, although it is usually considered distinct from most other alternators, which use field coils rather than permanent magnets. Hand-cranked magneto generators were used to provide ringing current in telephone systems. Magnetos were also adapted to produce pulses of high voltage in the ignition systems of some gasoline-powered internal combustion engines to provide power to the spark plugs. Use of such ignition magnetos for ignition is now limited mainly to engines without a low-voltage electrical system, such as lawnmowers and chainsaws, and to aircraft engines, in which keeping the ignition independent of the rest of the electrical system ensures that the engine continues running in the event of alternator or battery failure. For redundancy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

BSA A65 Star

The BSA A65 Star was a Birmingham Small Arms Company (BSA) motorcycle aimed at the US market for unit construction twins. As well as giving a clean look to the engine, with the pushrod passages part of the cylinder block casting, unit construction reduced the number of places oil could leak from. A range of A65 Star twins was produced between 1962 and 1972. Development The decision by Lucas in the late 1950s to switch production of motorcycle electrical components (from magneto/dynamo systems to alternators/coil systems) forced British motorcycle manufacturers to completely redesign their engines. Triumph and BSA took the opportunity to move from pre-unit and semi-unit construction to full unit construction, that is, with the engine and gearbox together in an integrated casting. At the same time, Bob Fearon, managing director and general manager of BSA, recognised the need for a new look that built on the best features of the A10s but would succeed in the potentially lucrative, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

BSA Royal Star

The BSA Royal Star was a Birmingham Small Arms Company (BSA) motorcycle whose new engine design paved the way for a range of successful unit construction twins. As well as giving a clean look to the engine, with the pushrod passages part of the cylinder block casting, unit construction reduced the number of places oil could leak from. Development The decision by Lucas in the late 1950s to switch production of motorcycle electrical components (from magneto/dynamo systems to alternator/coil systems) forced British motorcycle manufacturers to completely redesign their engines. Triumph and BSA took the opportunity to move from pre-unit and semi-unit construction to full unit construction, that is, with the engine and gearbox together in an integrated casting. At the same time, Bob Fearon, Managing Director and General Manager of BSA recognised the need for an updated look that built on the best features of the A10 but which would succeed in the potentially lucrative but competitiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

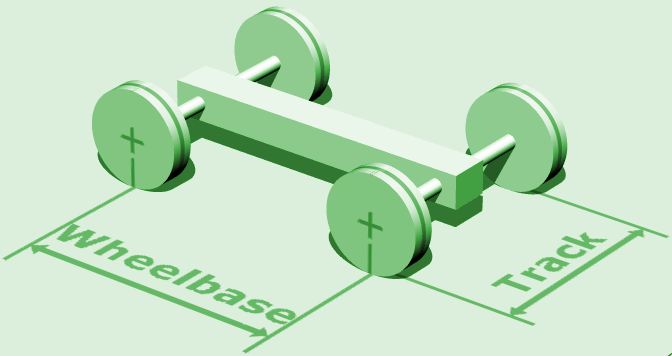

Wheelbase

In both road and rail vehicles, the wheelbase is the horizontal distance between the centers of the front and rear wheels. For road vehicles with more than two axles (e.g. some trucks), the wheelbase is the distance between the steering (front) axle and the centerpoint of the driving axle group. In the case of a tri-axle truck, the wheelbase would be the distance between the steering axle and a point midway between the two rear axles. Vehicles The wheelbase of a vehicle equals the distance between its front and rear wheels. At equilibrium, the total torque of the forces acting on a vehicle is zero. Therefore, the wheelbase is related to the force on each pair of tires by the following formula: :F_f = mg :F_r = mg where F_f is the force on the front tires, F_r is the force on the rear tires, L is the wheelbase, d_r is the distance from the center of mass (CM) to the rear wheels, d_f is the distance from the center of mass to the front wheels (d_f + d_r = L), m is the mass ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Motorcycle Fork

A motorcycle fork connects a motorcycle's front wheel and axle to its frame, typically via a yoke, also known as a triple clamp, which consists of an upper yoke joined to a lower yoke via a steering stem, a shaft that runs through the steering head, creating the steering axis. Most forks incorporate the front suspension and front brake, and allow the front wheel to rotate about the steering axis so that the bike may be steered. Most handlebars attach to the top clamp in various ways, while clip-on handlebars clamp to the fork tubes, either just above or just below the upper triple clamp. The fork and its attachment points on the frame establish the critical geometric parameters of rake and trail, which play a major role in defining how a motorcycle handles and dives during braking. While the standard telescopic fork arrangement is found with few major differences among mainstream street motorcycles since the 1970s, historically there have been many variations, including trailin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shock Absorber

A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated. Most shock absorbers are a form of dashpot (a damper which resists motion via viscous friction). Description Pneumatic and hydraulic shock absorbers are used in conjunction with cushions and springs. An automobile shock absorber contains spring-loaded check valves and orifices to control the flow of oil through an internal piston (see below). One design consideration, when designing or choosing a shock absorber, is where that energy will go. In most shock absorbers, energy is converted to heat inside the viscous fluid. In hydraulic cylinders, the hydraulic fluid heats up, while in air cylinders, the hot air is usually exhausted to the atmosphere. In other types of shock absorbers, such as electromagnetic types, the dissipated energy can be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Swinging Arm

A swingarm, or "swinging arm" (UK), originally known as a swing fork or pivoted fork, is a single or double sided mechanical device which attaches the rear wheel of a motorcycle to its body, allowing it to pivot vertically. The main component of the rear suspension of most modern motorbikes and ATVs, it holds the rear axle firmly, while pivoting to absorb bumps and suspension loads induced by the rider, acceleration, and braking. Originally motorcycles had no rear suspension, as their frames were little more than stronger versions of the classic diamond frame of a bicycle. Many types of suspension were tried, including Indian's leaf spring suspended swingarm, and Matchless's cantilevered coiled-spring swingarm. Immediately before and after World War II, the plunger suspension, in which the axle moved up and down two vertical posts, became commonplace. In the latter, the movement in each direction was against coiled springs. Some manufacturers, such as Greeves, used swingarm d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plain Bearing

A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing), is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal (i.e., the part of the shaft in contact with the bearing) slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe. Plain bearings, in general, are the least expensive type of bearing. They are also compact and lightweight, and they have a high load-carrying capacity. Design The design of a plain bearing depends on the type of motion the bearing must provide. The three types of motions possible are: * ''Journal'' (''friction'', ''radial'' or ''rotary'') ''bearing'': This is the most common type of p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball Bearing

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other. Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races. History Although bearings had been developed since ancient times, the first mod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling-element Bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls on to it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See " bearings" for more on the historical development of bearings. A rolling element rotary bearing uses a shaft in a much larger hole, and cylinders called "rollers" tightly fill the space between t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft located within the engine block, held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cylin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |