|

Anticipate, Recognize, Evaluate, Control, And Confirm

Anticipate, recognize, evaluate, control, and confirm (ARECC) is a decision-making framework and process used in the field of industrial hygiene (IH) to anticipate and recognize hazards, evaluate exposures, and control and confirm protection from risks (Figure 1). ARECC supports hazard-informed exposure assessment, exposure-informed hazard assessment, and risk-informed decision making in any endeavor. History The ARECC decision-making framework began as ''recognize, evaluate, and control''. In 1994 then-president of the American Industrial Hygiene Association (AIHA) Harry Ettinger added the ''anticipate'' step to formally convey the duty and opportunity of the worker protection community to proactively apply its growing body of knowledge and experience to assessing and managing hazards, exposures, and resulting risks in existing and emerging situations. The ''confirm'' step was added in 2011 to clarify the necessity of confirming that all steps in the decision-making framework wer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Hygiene

Occupational hygiene (United States: industrial hygiene (IH)) is the anticipation, recognition, evaluation, control, and confirmation (ARECC) of protection from hazards at work that may result in injury, illness, or affect the well being of workers. These hazards or stressors are typically divided into the categories biological, chemical, physical, ergonomic and psychosocial. The risk of a health effect from a given stressor is a function of the hazard multiplied by the exposure to the individual or group. For chemicals, the hazard can be understood by the dose response profile most often based on toxicological studies or models. Occupational hygienists work closely with toxicologists (see Toxicology) for understanding chemical hazards, physicists (see Physics) for physical hazards, and physicians and microbiologists for biological hazards (see Microbiology Tropical medicine Infection). Environmental and occupational hygienists are considered experts in exposure science and ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bisphenol A

Bisphenol A (BPA) is a chemical compound primarily used in the manufacturing of various plastics. It is a colourless solid which is soluble in most common organic solvents, but has very poor solubility in water. BPA is produced on an industrial scale by the condensation of phenol and acetone, and has a global production scale which is expected to reach 10 million tonnes in 2022. BPA's largest single application is as a co-monomer in the production of polycarbonates, which accounts for 65–70% of all BPA production. The manufacturing of epoxy resins and vinyl ester resins account for 25–30% of BPA use. The remaining 5% is used as a major component of several high-performance plastics, and as a minor additive in PVC, polyurethane, thermal paper, and several other materials. It is not a plasticizer, although it is often wrongly labelled as such. The health effects of BPA have been the subject of prolonged public and scientific debate. BPA is a xenoestrogen, exhibiting hormone ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Prevention Through Design

Prevention through design (PtD), also called safety by design usually in Europe, is the concept of applying methods to minimize occupational hazards early in the design process, with an emphasis on optimizing employee health and safety throughout the life cycle of materials and processes. It is a concept and movement that encourages construction or product designers to "design out" health and safety risks during design development. The concept supports the view that along with quality, programme and cost; safety is determined during the design stage. It increases the cost-effectiveness of enhancements to occupational safety and health. This method for reducing workplace safety risks lessens workers' reliance on personal protective equipment, which is the least effective of the hierarchy of hazard control.National Institute for Occupational Safety and HealthPrevention through Design Accessed 9/24/08. Background Each year in the U.S., 55,000 people die from work-related injuries ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

American National Standards Institute

The American National Standards Institute (ANSI ) is a private non-profit organization that oversees the development of voluntary consensus standards for products, services, processes, systems, and personnel in the United States. The organization also coordinates U.S. standards with international standards so that American products can be used worldwide. ANSI accredits standards that are developed by representatives of other standards organizations, government agencies, consumer groups, companies, and others. These standards ensure that the characteristics and performance of products are consistent, that people use the same definitions and terms, and that products are tested the same way. ANSI also accredits organizations that carry out product or personnel certification in accordance with requirements defined in international standards. The organization's headquarters are in Washington, D.C. ANSI's operations office is located in New York City. The ANSI annual operating b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Personal Protective Equipment

Personal protective equipment (PPE) is protective clothing, helmets, goggles, or other garments or equipment designed to protect the wearer's body from injury or infection. The hazards addressed by protective equipment include physical, electrical, heat, chemicals, biological hazard, biohazards, and Atmospheric particulate matter, airborne particulate matter. Protective equipment may be worn for job-related occupational safety and health purposes, as well as for sports and other recreation, recreational activities. ''Protective clothing'' is applied to traditional categories of clothing, and ''protective gear'' applies to items such as pads, guards, shields, or masks, and others. PPE suits can be similar in appearance to a cleanroom suit. The purpose of personal protective equipment is to reduce employee exposure to hazards when engineering controls and administrative controls are not feasible or effective to reduce these risks to acceptable levels. PPE is needed when there a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Administrative Controls

Administrative controls are training, procedure, policy, or shift designs that lessen the threat of a hazard to an individual. Administrative controls typically change the behavior of people (e.g., factory workers) rather than removing the actual hazard or providing personal protective equipment (PPE). Administrative controls are fourth in larger hierarchy of hazard controls, which ranks the effectiveness and efficiency of hazard controls. Administrative controls are more effective than PPE because they involve some manner of prior planning and avoidance, whereas PPE only serves only as a final barrier between the hazard and worker. Administrative controls are second lowest because they require workers or employers to actively think or comply with regulations and do not offer permanent solutions to problems. Generally, administrative controls are cheaper to begin, but they may become more expensive over time as higher failure rates and the need for constant training or re-certif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineering Controls

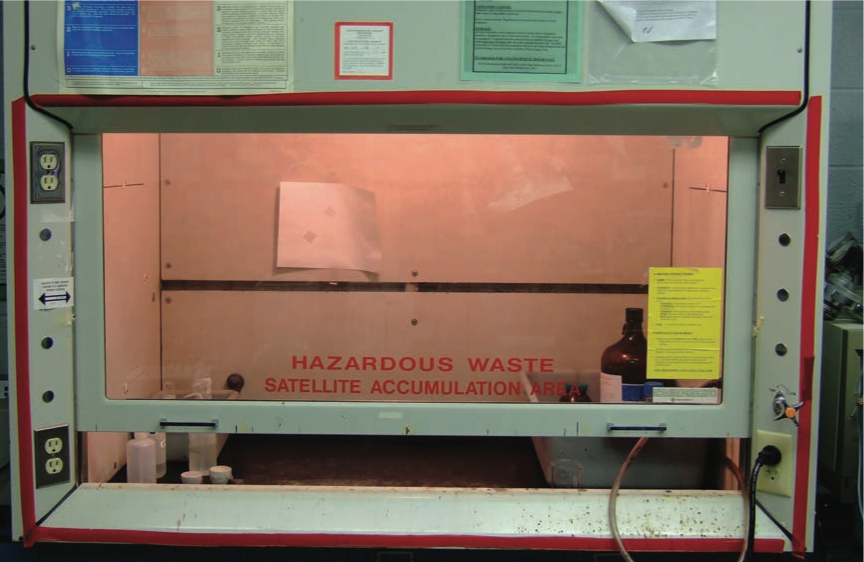

Engineering controls are strategies designed to protect workers from hazardous conditions by placing a barrier between the worker and the hazard or by removing a hazardous substance through air ventilation. Engineering controls involve a physical change to the workplace itself, rather than relying on workers' behavior or requiring workers to wear protective clothing. Engineering controls is the third of five members of the hierarchy of hazard controls, which orders control strategies by their feasibility and effectiveness. Engineering controls are preferred over administrative controls and personal protective equipment (PPE) because they are designed to remove the hazard at the source, before it comes in contact with the worker. Well-designed engineering controls can be highly effective in protecting workers and will typically be independent of worker interactions to provide this high level of protection. The initial cost of engineering controls can be higher than the cost of ad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bisphenol S

Bisphenol S (BPS) is an organic compound with the formula (HOC6H4)2SO2. It has two phenol functional groups on either side of a sulfonyl group. It is commonly used in curing fast-drying epoxy resin adhesives. It is classified as a bisphenol, and a close molecular analog of Bisphenol A (BPA). BPS differentiates from BPA by possessing a sulfone group (SO2) as the central linker of the molecule instead of a dimethylmethylene group (C(CH3)2), which is the case of Bisphenol A. Use BPS is used in curing fast-drying epoxy glues and as a corrosion inhibitor. It is also commonly used as a reactant in polymer reactions. BPS has become increasingly common as a building block in polyethersulfone and some epoxies, following the public awareness that BPA has estrogen-mimicking properties, and widespread-belief that enough of it remains in the products to be dangerous. However, BPS may have comparable estrogenic effects to BPA. BPS is now used to a variety of common consumer products. In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

American Industrial Hygiene Association

The American Industrial Hygiene Association (AIHA) is a 501(c)6 non-profit organization, whose mission is "Creating knowledge to protect worker health." The American Industrial Hygiene Association works to provide information and resources to Industrial Hygienists and Occupational Health professionals. About The American Industrial Hygiene Association (AIHA) is an official participant of the OSHA Alliance Program. Through the AIHA-OSHA Alliance, AIHA helps OSHA provide AIHA members and the general public information on OSHA's rule making and employer compliance laws, in order to fulfill the mutual mission of ensuring safe and healthy conditions for workers. The actionable plan is twofold: 1). raise awareness, and 2). be a source of outreach and communication. AIHA worked with OSHA to provide resources available to employers and employees regarding specific hazards pertaining to relevant industries, in order to create awareness with workers and employers. AIHA has provided several a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hazard Substitution

Hazard substitution is a hazard control strategy in which a material or process is replaced with another that is less hazardous. Substitution is the second most effective of the five members of the hierarchy of hazard controls in protecting workers, after elimination. Substitution and elimination are most effective early in the design process, when they may be inexpensive and simple to implement, while for an existing process they may require major changes in equipment and procedures. The concept of prevention through design emphasizes integrating the more effective control methods such as elimination and substitution early in the design phase. Hazard substitutions can involve not only changing one chemical for another, but also using the same chemical in a less hazardous form. Substitutions can also be made to processes and equipment. In making a substitution, the hazards of the new material should be considered and monitored, so that a new hazard is not unwittingly introdu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hazard Elimination

Hazard elimination is a hazard control strategy based on completely removing a material or process causing a hazard. Elimination is the most effective of the five members of the hierarchy of hazard controls in protecting workers, and where possible should be implemented before all other control methods. Many jurisdictions require that an employer eliminate hazards if it is possible, before considering other types of hazard control. Elimination is most effective early in the design process, when it may be inexpensive and simple to implement. It is more difficult to implement for an existing process, when major changes in equipment and procedures may be required. Elimination can fail as a strategy if the hazardous process or material is reintroduced at a later stage in the design or production phases. The complete elimination of hazards is a major component to the philosophy of Prevention through Design, which promotes the practice of eliminating hazards at the earliest design s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |