|

Advanced Fiber Placement

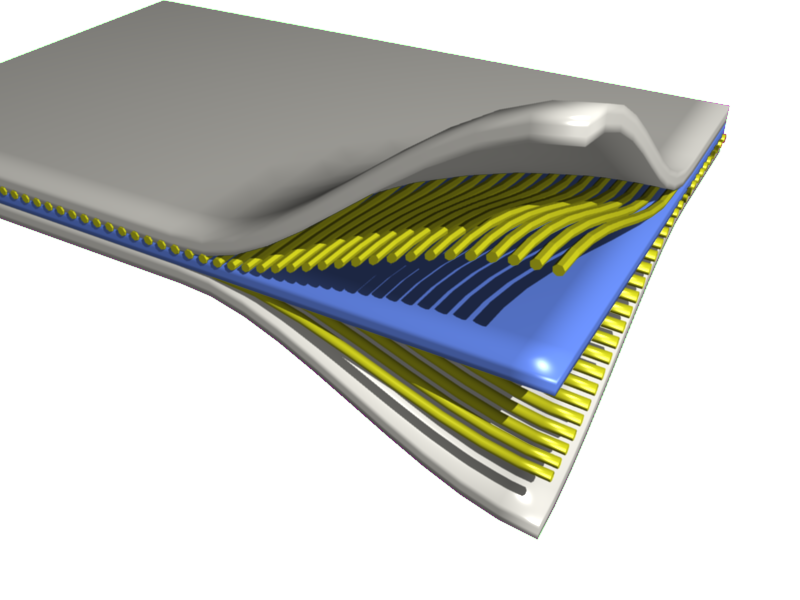

Automated fiber placement (AFP), also known as advanced fiber placement, is an advanced method of manufacturing composite materials. These materials, which offer lighter weight with equivalent or greater strength than metals, are increasingly used in airframes and other industrial products. Fiber Placement is an automated composites manufacturing process of heating and compacting synthetic resin pre-impregnated non-metallic fibers on typically complex tooling mandrels. The fiber usually comes in the form of what are referred to as "tows". A tow is typically a bundle of carbon fibers impregnated with epoxy resin and is approximately wide by thick and comes on a spool. Fiber placement machines (FPM) generally have a capacity of 12 to 32 tows or when placing all tows at a time in a course, have respective course widths of 1.5 in to 4 in. The tows are fed to a heater and compaction roller on the FPM head and through robotic type machine movements, are placed in courses across a to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Typical Materials, engineered composite materials include: *Reinforced concrete and masonry *Composite wood such as plywood *Reinforced plastics, such as fibre-reinforced polymer or fiberglass *Ceramic matrix composites (composite armor, composite ceramic and metal matrices) *Metal matrix composites *and other Advanced composite materials (engineering), advanced composite materials There are various reasons where new material can be favoured. Typical examples include materials which are less ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Airframe

The mechanical structure of an aircraft is known as the airframe. This structure is typically considered to include the fuselage, undercarriage, empennage and wings, and excludes the propulsion system. Airframe design is a field of aerospace engineering that combines aerodynamics, materials technology and manufacturing methods with a focus on weight, strength and aerodynamic drag, as well as reliability and cost.Michael C. Y. Niu (1988). ''Airframe Structural Design''. Conmilit Press LTD. History Modern airframe history began in the United States when a 1903 wood biplane made by Orville and Wilbur Wright showed the potential of fixed-wing designs. In 1912 the Deperdussin Monocoque pioneered the light, strong and streamlined monocoque fuselage formed of thin plywood layers over a circular frame, achieving . First World War Many early developments were spurred by military needs during World War I. Well known aircraft from that era include the Dutch desig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Synthetic Resin

Synthetic resins are industrially produced resins, typically viscous substances that convert into rigid polymers by the process of curing. In order to undergo curing, resins typically contain reactive end groups, such as acrylates or epoxides. Some synthetic resins have properties similar to natural plant resins, but many do not. Synthetic resins are of several classes. Some are manufactured by esterification of organic compounds. Some are thermosetting plastics in which the term "resin" is loosely applied to the reactant(s), the product, or both. "Resin" may be applied to one of two monomers in a copolymer, the other being called a "hardener", as in epoxy resins. For thermosetting plastics that require only one monomer, the monomer compound is the "resin". For example, liquid methyl methacrylate is often called the "resin" or "casting resin" while in the liquid state, before it polymerizes and "sets". After setting, the resulting poly(methyl methacrylate) (PMMA) is often r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mandrel

A mandrel, mandril, or arbor is a gently tapered cylinder against which material can be forged or shaped (e.g., a ring mandrel - also called a triblet - used by jewelers to increase the diameter of a wedding ring), or a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel (often called a plain mandrel) has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an identical thread is screwed onto the mandrel. On a lathe, mandrels are commonly mounted between centres and driven by a lathe dog (typically the flanged or tapered mandrels), but may also be gripped in a ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epoxy Resin

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted ( cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (usually called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of applications, including metal coatings, composites, u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoset

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening ("curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure, or mixing with a catalyst. Heat is not necessarily applied externally, but is often generated by the reaction of the resin with a curing agent (''catalyst'', '' hardener''). Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network. The starting material for making thermosets is usually malleable or liquid prior to curing, and is often designed to be molded into the final shape. It may also be used as an adhesive. Once hardened, a thermoset cannot be melted for reshaping, in contrast to thermoplastic polymers which are commonly produced and distributed in the form of pellets, and shaped into the final product for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers (or "thermosets"), which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling. Above its glass transition temperature and below its melting point, the physical properties of a thermoplastic change drastically without an associated phase change. Some thermoplastics do not fully cry ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Typical Materials, engineered composite materials include: *Reinforced concrete and masonry *Composite wood such as plywood *Reinforced plastics, such as fibre-reinforced polymer or fiberglass *Ceramic matrix composites (composite armor, composite ceramic and metal matrices) *Metal matrix composites *and other Advanced composite materials (engineering), advanced composite materials There are various reasons where new material can be favoured. Typical examples include materials which are less ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ingersoll Machine Tools

Ingersoll Machine Tools is a manufacturer located in Rockford, Illinois that produces large scale machine tools for use in metal cutting, 3D Printing, and automated fiber placement. History The company was founded in 1891 by Winthrop Ingersoll when he moved W.R. Eynon & Co. from Cleveland, Ohio to Rockford. Originally, Ingersoll Machine Tools focused almost entirely on milling machinery and processes for metal removal. It acquired contracts from General Electric and, by 1917, was closely involved with wartime production and had a workforce of 600. It went on to produce customized machines for industries such as airplane and auto manufacturing. In the period from the 1960s to the 1980s, the company employed around 2,000 people at its plant, also developing CNC technologies to introduce automation into its manufacturing processes. Bankruptcy In 2003, Ingersoll International went bankrupt. The company was purchased by the Italian Camozzi Group. Since its purchase by Camozzi, the c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |